National Composites Centre launches net-zero flight plan

New technology innovation partnership program with South West Europe IAAPs and the universities of Bristol and Bath will focus on hydrogen fuel systems to increase U.K. technology, infrastructure and innovation capabilities.

A technology innovation partnership for net-zero aviation in the South West of Europe has been launched. Focused on delivering transformational innovation to advance net-zero flight, the founding partners are the National Composites Centre (NCC, Bristol, U.K.), advanced propulsion R&I center IAAPS (Bath, U.K.), and the universities of Bristol and Bath. The partnership anticipates the creation of a significant national capability that, combined, will exceed working independently.

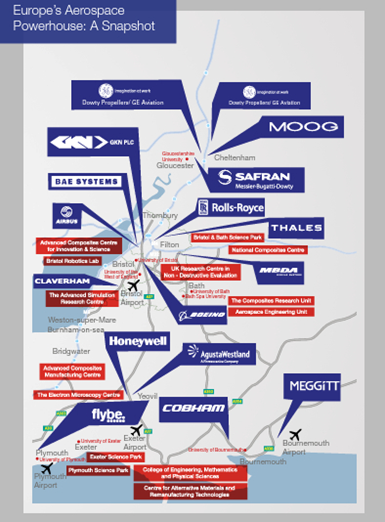

The South West is home to an aerospace and advanced engineering cluster worth more than £7 billion. Leveraging more than £250 million of investment that partners have already secured to underpin technology, infrastructure and innovation capabilities, the partnership will further embed the region’s research and innovation leadership in the decarbonization of aviation.

Consultation with industry-leading organizations has identified a set of pre-competitive challenge areas that will underpin technology exploration. These range from new cryogenic-suitable materials, their characterization and industrial application, through to the design, manufacture and testing of sub-systems. These will form the basis of Joint Industry Programs to be announced later this year. Together, they will help establish a strong hydrogen supply chain.

An underpinning theme across the program is materials innovation, crucial for future aircraft. This will be led by the NCC’s expertise in high-performance composites, combined with the exploration of novel materials initiatives by Bristol Composites Institute and Bristol Innovations, through the University of Bristol. The academic strengths of Bristol and Bath universities in translational research will lay the foundation of the partnership’s rapid development of net-zero technologies. Moreover, IAAPS, a commercial subsidiary of the University of Bath, ranked among the top three independent R&I centers, supports industry in the development and validation of zero carbon propulsion technologies for integration into commercial applications.

Photo Credit: Invest Bristol & Bath

Boosted by R&D advances each organization has achieved, a combined focus will be on innovating hydrogen fuel systems. The NCC has successfully designed, manufactured and tested a composite cryogenic storage tank with liquid hydrogen (LH2), and will launch its manufacturing and test facility for hydrogen storage at the end of the year, while IAAPS is leading on strategic ventures to develop hydrogen fuel-cell powered transport, with a key focus on aircraft. More than £56.5 million of industry funding, grant capture as well as training and capability building awards have been invested in pioneering hydrogen-related initiatives at IAAPS and the University of Bath.

“Combining our respective strengths and expertise will catalyze transformative change for net-zero aviation in the South West,” Richard Oldfield, chief executive, NCC, says. “As a collaboration, our commitment to decarbonizing aviation will unlock the full potential of hydrogen-powered aircraft and cutting-edge propulsion systems, enabling industry to accelerate engineering expertise, and secure future U.K. commercial competitiveness.”

Industry organizations interested in engaging with the partnership can contact NCC Strategic Partnerships at strategicpartnerships@nccuk.com or IAAPS Commercial and Strategic Partnerships at iaaps@iaaps.co.uk.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.