Additive Manufacturing

Cincinnati’s BAAM proves utility of recycled materials in AM

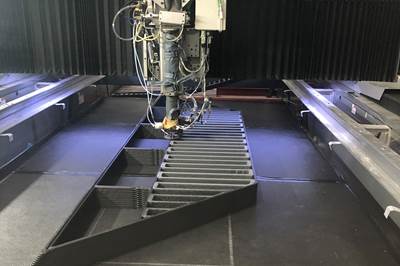

Cincinnati Inc. modified the extruder of its Big Area Additive Manufacturing (BAAM) system to be able to process virgin carbon fiber/ABS and recycled carbon fiber/ABS.

Read MoreContinuous fiber-reinforced, 3D printed houses on the horizon

3D-printed modular building manufacturer Mighty Buildings moves toward certification of higher-strength, more sustainable glass fiber-reinforced housing panels.

Read MoreQ&A: Importance of reliability in large-scale additive manufacturing

Thermwood Corp. CEO Ken Susnjara shares an LSAM supplier’s perspective on enabling reliable, continuous manufacturing performance.

Read MoreMarkforged next-generation fiber-reinforced 3D printer

Markforged will debut its newest continuous fiber-capable 3D printer, the FX20, at Formnext in November 2021.

Read MoreTeton Simulation joins Stratasys GrabCAD Software Partner Program

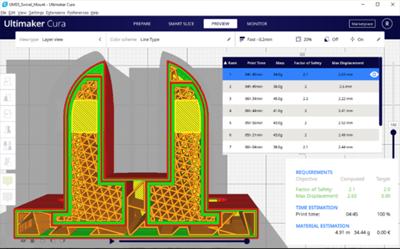

Teton’s SmartSlice software for plastics and polymers will be integrated with GrabCAD DFAM Software Development Kit for improved print parameter validation and optimization.

Read MoreRegistration opens for Additive Manufacturing Conference + Expo 2021

Additive Manufacturing Media leading event for industrial 3D printing is expanding to include an expanded exhibit hall, speakers, exhibitors and networking opportunities.

Read MoreVictrex launches LMPAEK polymer grade for 3D printing

Victrex AM 200 improve melt extrusion by filament fusion (FF), direct granule extrusion, and laser sintering processes and enhances z-strength and interlaminar strength.

Read MoreCEAD launches new E50 Robot Extruder for larger 3D-printed composites

New option offers higher material output (e.g., 84 kg/hr) and thermoplastic melt temperatures up to 400°C.

Read MoreArkema acquires 10% stake in additive manufacturer ERPRO 3D Factory

Investment enables Arkema to accelerate new development opportunities for high-performance polymers and potential fiber-reinforced materials in additive manufacturing.

Read MoreSABIC, Local Motors conduct feasibility study for reprocessed, 3D-printed thermoplastic parts and shavings

Anticipating the wider adoption of LFAM, the study explored more sustainable alternatives to landfilling large, printed parts, with results indicating the potential for material reuse.

Read More

.jpg;maxWidth=300;quality=90)