Additive Manufacturing

Swinburne 4.0 test lab to feature Fill's multilayer printing technology

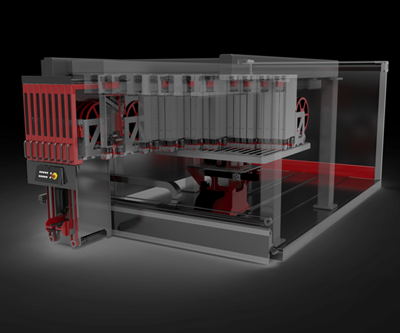

The centrepiece of Swinburne’s testlab is the world’s first industrial scale 3D printing “multilayer” approach to carbon fibre composite manufacture developed by Fill.

Read MoreLehvoss partners with Livrea Yacht to build 3D printed sailboat

World’s first 3D printed yacht to compete in the 2019 Mini-Transat solo transatlantic yacht race.

Read MoreCevotec and Composite Automation announce partnership agreement

The two companies join forces to meet the demand for automation solutions of North American composite manufacturers.

Read MoreSGL Group and ExOne collaborate to bring carbon to 3D printing market

Trial components made with CARBOPRINT are being developed for testing.

Read MoreJEC World 2018 preview: e-Xstream engineering

Digimat 2018 revolutionary material modeling platform

Read MoreCENIT presents initial results for bionic aircraft design project

CENIT reports development of CAD design tool for automated generation of bionic components and output for additive manufacturing.

Read MoreStratasys brings 3D printing to the Olympics

Stratasys teams with USA Luge to inject additive manufacturing into its quest for gold in Pyeongchang, South Korea this month.

Read MoreORNL offering additive manufacturing/composites post-doc

The postdoctoral position at Oak Ridge National Laboratory (ORNL) will conduct research in additive manufacturing related to advancement of current technologies, implementation of new processes, and development of material systems.

Read More3D printing for a Bonneville run

As a former (amateur vintage) racer myself, I appreciate all things motorsports. CRP USA LLC (Mooresville, NC, US), the maker of Windform SLS 3D printing materials as well as provider of custom additive manufacturing and machining services, sent me a case study of a motorsports team that recently set a new class record at the Bonneville Salt Flats, thanks to the fast part production possible with 3D printing.

Read More3D-printed composite wind blades and aircraft, closer than you think

Orbital Composites’ patented coaxial extrusion process is investigated at Airbus subsidiary CTC GmbH Stade and spins off advances in speed, scale, materials and multifunctionality as it aims for very large structures.

Read More