Additive Manufacturing

Generative design and continuous 3D fiber deposition

Generative design replicates nature’s evolutionary approach by combining artificial intelligence (AI) and cloud computing to provide thousands of solutions to one engineering problem.

WatchHenkel opens Innovation and Interaction Center for 3D Printing

The center will be Henkel’s European regional hub for technology presentations, demonstrations, training and testing, as well as customer service for 3D Printing solutions.

Read MoreArevo's 3D-printed commuter bike supported by Hexcel carbon fiber

Arevo recently secured financing to build on the full-scale commercialization of the technology demonstrated by the world’s first true 3D-printed bike.

Read MoreStartup company sets sights on tailor-made thermoset composite parts

Researchers from Politecnico di Milano’s +LAB, winner of 2017 JEC Innovation Award, have started Moi Composites to offer tailor-made thermoset high performance parts.

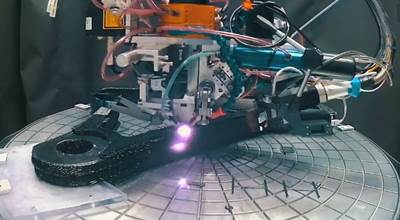

WatchArevo in 2018: Industrialized production of continuous fiber 3D-printed parts

With new CEO and $12.5 million in B-series financing, Arevo will have eight direct energy deposition (DED) cells attacking its parts production backlog by year-end.

WatchSABIC launches new filaments for fused deposition modeling

The new filaments add to the company’s fast-growing additive manufacturing materials portfolio.

Read MoreMade In Space to propose Phase II of Archinaut technology to NASA

The core technology of Archinaut is the Extended Structure Additive Manufacturing Machine, an additive manufacturing capability that enables manufacturing of large structures in space.

WatchM. Holland Co. to distribute Owens Corning filaments for 3D printing

M. Holland will manage a network of sub-distributors and directly distribute XSTRAND filaments to M. Holland clients in the thermoplastic resin industry

Read MoreAdditive manufacturing factory floor solutions from Stratasys

Stratasys has unveiled a range of new solutions designed to accelerate the use of additive manufacturing on the factory floor.

Read MoreAdditive manufacturing: Big and going commercial

A demonstration of large-format 3D printing delivers parts for an excavator cab, from CAD data to ready for assembly, in only five hours.

Read More