Aerospace

Perseverance rover landing previews touchdown footage

NASA’s Perseverance rover relays a high-resolution still shot of its descent to the surface of Mars. Rover indicates positive health reports.

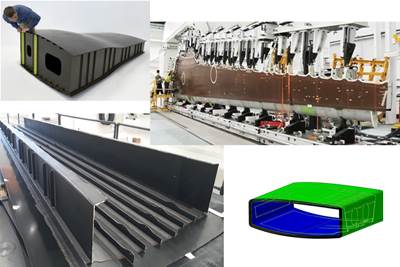

Read MoreAdvancing the OOA infused wing box

MTorres integrates lower cover, front and rear spars into unitized flying demonstrator using one-shot, low-cost, portable production.

Read MoreThe path to OOA wings with minimal fasteners

A review of the quest to eliminate both the autoclave and mechanical fasteners in composite wing structures.

WatchHot drape forming

Heat, vacuum and/or pressure advance from debulking prepreg layups to automated preforming of dry reinforcements for faster composites production.

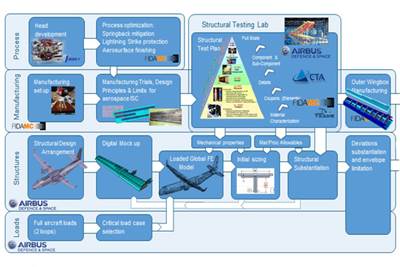

Read MoreIIAMS wing box road map to certification

Airbus DS uses Clean Sky demonstrators as part of broad strategy to ready next-gen aircraft technology for flight.

Read MoreEmbraer delivers 71 jets in Q4 2020, 130 total in 2020

Although deliveries accelerated during the fourth quarter of 2020 relative to the three previous quarters, 2020 numbers represents a decrease of almost 35% compared to 2019.

Read MoreCFRP use expanded in Porsche 911 GT3

Bigger than its predecessor, but with only a slight increase in mass thanks to light weight body panels.

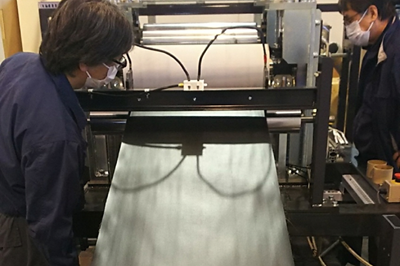

Read MoreMaruHachi installs new UD tape line for high-end applications

New focus on high-temperature thermoplastic tapes and multi-layer sheet laminates for aerospace, automotive and other demanding market segments.

Read MoreSelf-responsive composite materials to reduce aerospace production costs, improve sustainability

EU Horizon 2020 MASTRO project to develop intelligent bulk materials with carbon nanotube integration for self-cure, self-anti-icing and self-sensing properties.

Read MorePerseverance rover takes one step for composites on Mars

The rover’s successful landing on Feb. 18 begins a two-year science investigation of Mars’ Jezero Crater for ancient microbial life.

Read More