IIAMS wing box road map to certification

Airbus DS uses Clean Sky demonstrators as part of broad strategy to ready next-gen aircraft technology for flight.

This online sidebar to the March 2021 article, “Advancing the OOA infused wing box,” gives more details regarding how Clean Sky 2 projects like IIAMS fit into road maps for maturing liquid resin infusion (LRI) and thermoplastic composite (TPC) technologies while completing the work required to certify them in out-of-autoclave (OOA) composite structures for next-generation aircraft.

Airbus DS, FTB#2 and future turboprop aircraft

Airbus Defence and Space (Airbus DS, Cadiz, Spain) entered the Clean Sky European Union research and technology program as EADS CASA. Founded as Construcciones Aeronáuticas SA in 1923 in Getafe, Spain, CASA has a long history in aircraft production and was one of the original members of the Airbus Consortium. Its second site was established in Cadiz in 1926, and the company has produced 22 aircraft models as well as components for Airbus and Eurofighter military aircraft and for commercial aircraft produced by Airbus and Boeing.

Airbus DS has progressed from a co-leader of the Green Regional Aircraft (GRA) integrated technology demonstrator (ITD) in the original Clean Sky program (2008-2017) to co-leader of the AIRFRAME ITD as well as leader for the flight test bed 2 (FTB#2) in the REGIONAL integrated aircraft demonstrator platform (IADP) within the follow-on Clean Sky 2 program (2014-2024).

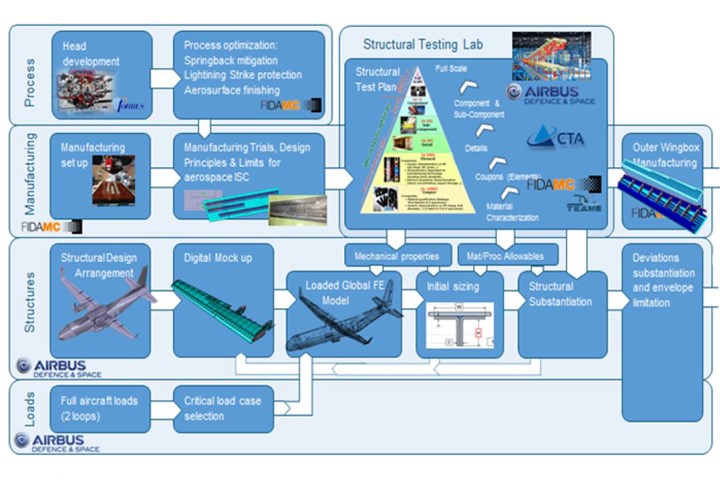

A.E. Jiménez Gahete, with the Structures and Design, Engineering & Technology Directorate at Airbus DS, describes FTB#2 development in the Sep 2020 Materiales Compuestos article titled, “Airbus Defence and Space highly integrated wing box section manufactured by dry fiber placement and liquid resin infusion”. This work by Airbus DS in Clean Sky 2 will be applied to a future military transport or commercial regional turboprop aircraft. One of its main objectives is to develop the external wing for the FTB#2, which will feature OOA composite primary structures, including an integrally stiffened thermoplastic composite upper wing box cover and a one-piece, one-shot wing box made using automated fiber placement (AFP) with dry fiber tapes and liquid resin infusion.

The latter is indeed the structure MTorres developed and produced within the Clean Sky 2 IIAMS project, as described in CompositesWorld’s March 2020 article, “Advancing the OOA infused wing box.” Notably, that wing box integrates the lower skin, front and rear spars, but does not include the upper skin. It becomes obvious from the illustrated road maps below that the upper skin will be thermoplastic composite.

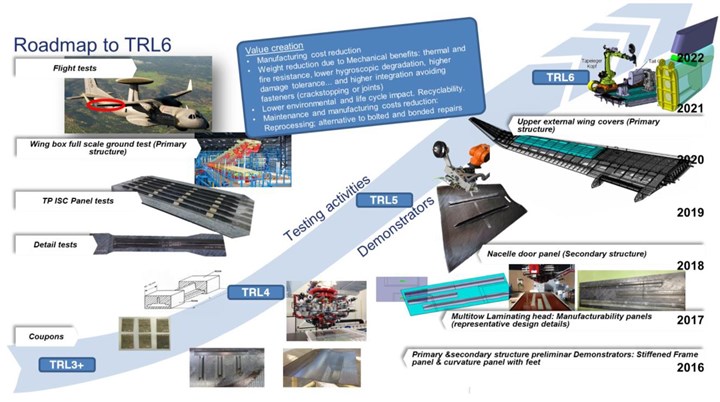

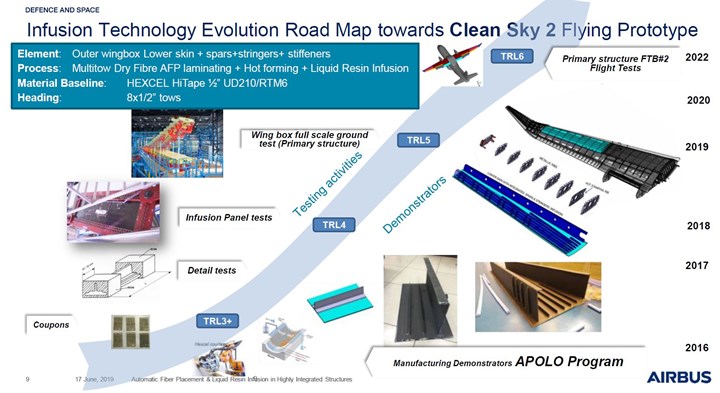

Fig. 8. Road map liquid resin infusion (LRI) manufacturing. Photo Credit: see below.

Fig. 9. Road map for thermoplastic composite (TPC) in-situ consolidation (ISC) manufacturing. Photo Credit: “Structural Radar Research of Airbus Defense and Space as Clean Sky Partnership” by Manuel Iglesias Vallejo, Rubén Tejerina Hernanz, Antonio Jiménez, et al., Airbus Defence and Space, 8th European Conference for Aeronautics and Space Sciences (EUCASS), July 1-4, 2019.

FTB#2 external wing goals and background

“Any future aircraft design will require more eco-efficiency into the whole life cycle,” says Gahete. This should include:

- Less energy into component production

- Less scrap primary material

- Decreased consumption of manufacturing liquids and ancillary materials

- Increased recyclability.

Such improvements were key factors in the development of the structural design and production process for the FTB#2 external wing, along with targets for reduced weight (-10%) and manufacturing cost as well as increased production efficiency.

Thermoplastic composites and resin infusion both play a key role in the FTB#2 external wing. In-situ consolidated (ISC) thermoplastic composites (TPC) and dry fiber/resin infusion enable large primary structures to be manufactured OOA at reduced cost compared to traditional autoclave-based processes. Thermoplastic welding and highly integrated structures infused in one shot also reduce the impact of assembly, mechanical fasteners, machining for those fasteners and inspection throughout.

Infusion technology developments in Clean Sky 2 started with previous Clean Sky projects such as GRA, ECO-DESIGN, APOLO and CERTERIN. Meanwhile, ISC TPC has been matured in Clean Sky projects ICARO, TARGET, ECO-DESIGN, and Green Regional Aircraft-Light Weight (GRA-LW), allowing this technology to be included in the Clean Sky 2 FTB#2 flight demonstrator.

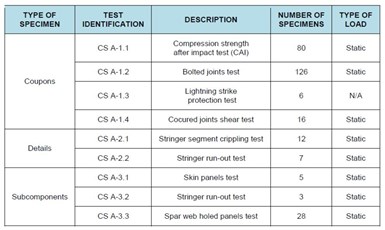

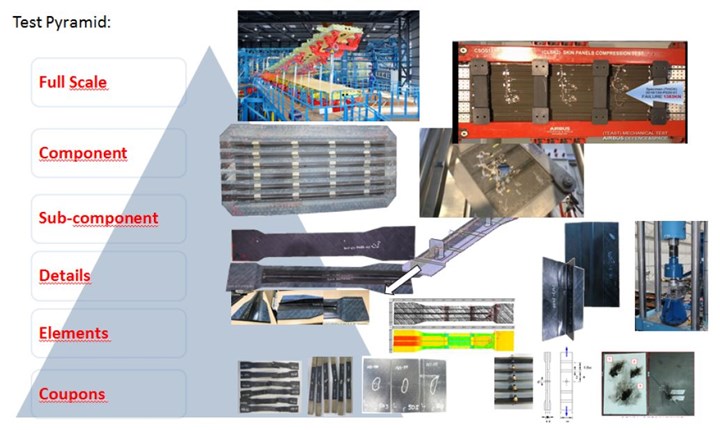

Fig. 10. Test pyramid. Photo Credit: “Airbus Defence and Space highly integrated wing box section manufactured by dry fiber placement and liquid resin infusion,” by A.E. Jiménez Gahete, Materiales Compuestos Vol. 4, No. 4, pp. 19-26, Sep 2020.

FTB#2 external wing certification

As explained by Gahete, “Step by step we [Airbus DS] are going through the entire airframe structures test pyramid from coupons to the full-scale structural tests of the outer wing.” Hexcel HiTape, UD 210 grams per square meter (gsm) and 12.7-mm wide with thermoplastic veil V800E on both sides (veil weight 4 gsm per side), infused with Hexcel HexFlow RTM6 180°C cure epoxy resin, has been fully characterized, including unidirectional and multi-angular properties. Test results showed that this material performs well in modulus but less well in strength compared to Hexcel’s HexPly M21E epoxy prepreg made with HexTow IMA intermediate carbon fiber, which is used to manufacture wing skins, spars and center wing box for the Airbus A350. Quasi-isotropic laminates showed good results compared to the same reference.

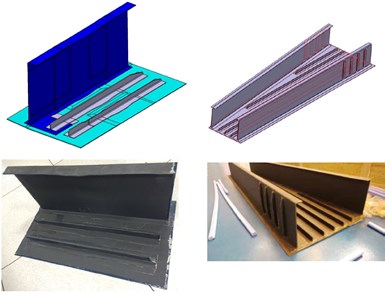

Figures 5-8. DEMO1 and DEMO2 manufacturing demonstrators. Photo Credit: Gahete, Materiales Compuestos Vol. 4, No. 4, pp. 19-26, Sep 2020.

Gahete explains that in addition to coupons for material characterization, and prior to details and panel subcomponent tests to obtain the design allowables, manufacturing demonstrators were used to help validate “which design features could be obtained with the selected manufacturing processes.” DEMO1 integrates a section of variable-thickness skin, J-spar with rib stiffeners and two stringers integrated into the skin and J-spar flange. And DEMO2 — measuring 3 meters long x 0.86 meter wide x 3.44 meters high — simulates the overall dimensions of the FTB#2 outer wing box and includes five stringers. Gahete notes that some process adjustments were made through a few iterations before obtaining successful results in structural part tests.

Fig. 9. Development test matrix for FTB#2 outer wing. Photo Credit: Gahete, Materiales Compuestos Vol. 4, No. 4, pp. 19-26, Sep 2020.

A design details test matrix was also completed, including lightning strike, stringer run-out and stringer crippling tests (for buckling and failure evaluation). Subcomponent panel tests have also been completed with positive results. With all of the test pyramid completed successfully, from coupons to subcomponents, says Gahete, only the final outer wing full-scale static and functional tests remain to obtain the FTB#2 qualification for flight. These tests are planned to be completed by the end of 2021.

FTB#2 as part of larger-scope technology development

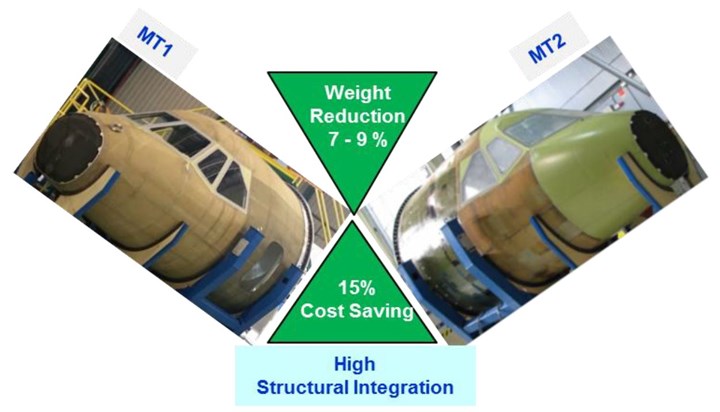

The external wing box is just one part of FTB#2 that Airbus DS is supplying. Other structural demonstrators — as explained in the 2019 paper, “Structural radar research of Airbus Defense and Space as Clean Sky partnership,” written by Airbus DS and published by the European Conference for Aeronautics and Space Sciences (EUCASS) in 2019 — include MT1 or MT2 cockpits (see image below) with high structural integration for weight and cost reduction, wing leading edges with morphing features and full external wing with winglet and morphing flap. (Note, the latter is being advanced via the Air Green 2 project by CIRA - Italian Aerospace Research Centre.)

MT1 and MT2 cockpit demonstrators. Photo Credit: Figure 2. CS1 (Clean Sky) GRA-LW (Green Regional Aircraft Light Weight) demonstrators to be exploited in CS2. “Structural Radar Research of Airbus Defense and Space as Clean Sky Partnership” published by (EUCASS), July 2019.

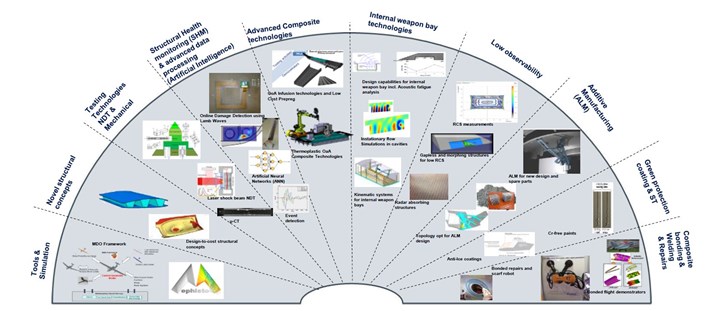

The illustration below shows various Airbus DS research within Clean Sky (CS1) and Clean Sky 2 (CS2), as part of a broad technology portfolio.

Fig. 1. Structural technology radar illustration. Photo Credit: “Structural Radar Research of Airbus Defense and Space as Clean Sky Partnership” by Manuel Iglesias Vallejo, Rubén Tejerina Hernanz, Antonio Jiménez, et al., Airbus Defence and Space, 8th European Conference for Aeronautics and Space Sciences (EUCASS), July 1-4, 2019.

Also explained in the EUCASS paper, these research projects have not only advanced composites technologies but also new developments in metals, as well as additive manufacturing, tooling and repair:

- Highly integrated primary structure

- One-shot co-cured stiffened multifunctional double-curved solid laminate

- High integration of bulk frames via liquid resin infusion (LRI)

- Solid laminate (lower former FR-9)

- Stiffened sandwich (forward pressure bulkhead FR-1)

- Lower skin and spars of FTB#2 wing box

- High integration via thermoplastic in-situ consolidation (ISC)

- Small curvature (FR-4 of MT1/MT2; upper skin of FTB#2 external wing box)

- Thermoplastic continuous forming (stringers)

- High/double curvature (leading edge and cowling)

- Fuselage frame/wing rib made in hot stamping light alloy sheet

- Secondary structure: low-cost TPC and ALM (additive layer manufacturing) window frames

- Tooling technologies: low-cost composite and ALM

- Repairs and maintenance

- Standard repair on highly integrated curved stiffened skin (pre-preg)

- Thermoplastic ISC co-consolidation and welding

- RTM-LRI structural items

- Prepreg patch application

- Dry material patches plus resin injection

- Resin injection to fix external multifunctional layers

Jig-less assembly has also been a recurring emphasis, as has maturing new 4.0 digital systems and testing technologies such as those listed in the EUCASS paper:

- Interferometry (DIC)

- Multi-impact mid energy testing

- Vibrational testing

- Thermography

- NDT application

- Structural behavior in hot environment

- SHM sensors and measurement techniques

- Fiber optics FBG (Fiber Bragg Grating)

- OBR (Optical Backscatter Reflectometry)

- MEMS (Micro-Electro-Mechanical Systems combining electrical and mechanical components on a single computer chip)

- p-U acoustic (pressure-velocity based in-situ absorption measurement method)

Collaborative EU framework for certification

A final note from the EUCASS and Gahete papers is the credit given to the close collaboration with and work accomplished by a number of key Airbus DS partners including NLR (Netherlands Aerospace Centre), Airborne (The Hague, Netherlands), Applus+ Laboratories (Barcelona, Spain), MTorres (Torres de Elorz, Spain) and FIDAMC (Getafe, Spain), the latter described as “significantly involved in all the technologies being developed with composite materials and their manufacturing processes.”

For some time, I have noted the activities and publications from engineers at Airbus in Getafe and written about the ISC TPC work done by FIDAMC and others. CW has also highlighted Airbus DS’ leadership in many of the articles written about Clean Sky projects. But until now, I did not understand how long-term and planned the Airbus DS strategy has been, making the most use of its participation in and contribution to Clean Sky programs. It makes perfect sense to lay the groundwork for certification during the development of new cockpit and wing demonstrators. CW wrote about this same approach being pursued by topic leader Airbus Germany within the Clean Sky 2 Multifunctional Fuselage Demonstrator (MFFD). In that case, full characterization of low-melt polyaryletherketone (LMPAEK) in welded joints will be achieved within the sub-project MECATESTERS.

The Airbus DS road maps and structural technology radar illustration shown in this report are yet another example of how the European aviation and composites industries are working together to be ready for the future. Clean Sky 2 continues to succeed by providing Europe’s aircraft and aerocomposites industries with an ambitious vision and a funded framework for working together to achieve clear targets. This work will also help as the industry pivots toward electrification, hydrogen and alternative fuels to overcome climate change, and both aviation and composites have key roles to play in that accomplishment.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More