Self-responsive composite materials to reduce aerospace production costs, improve sustainability

EU Horizon 2020 MASTRO project to develop intelligent bulk materials with carbon nanotube integration for self-cure, self-anti-icing and self-sensing properties.

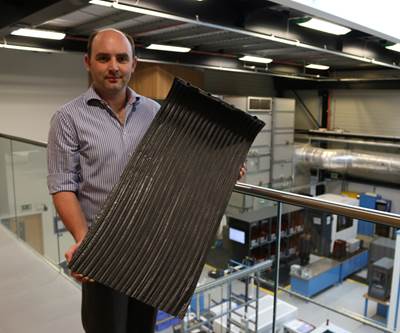

Research Engineer Matthew Collinson with a section of a composite leading-edge wing manufactured in the AMRC Composite Centre. Photo Credit: University of Sheffield AMRC.

According to the University of Sheffield Advanced Manufacturing Research Centre (AMRC, Catcliffe, U.K.), its composites researchers are currently at the heart of the European-wide MASTRO project to develop self-responsive aerospace composites that is said will significantly reduce greenhouse gas emissions and production costs in the aviation sector as it works toward a net zero goal by 2050.

For this project, the university is partnering with 16 industrial partners, which are tasked with developing intelligent bulk materials for a smart transport sector as part of Horizon 2020, an EU Research and Innovation program.

“There are three sections within MASTRO: automotive, infrastructure and aerospace. The AMRC is leading the aerospace section of the project alongside Embraer. We’re developing three main technologies: self-cure, self-anti-icing and self-sensing,” says Matthew Collinson, research engineer in the AMRC Composite Centre.

The AMRC team is developing materials through the integration of carbon nanotubes (CNTs) — measured in billionths of a meter — which can be turned into smart products, and are now in a position to demonstrate the advances they have made.

“For the first year-and-a-half we’ve been working on developing the materials, so the next stage is developing the smart demonstrators,” adds Matthew. “Now, we’ve reached a point where we can build a section of a composite leading-edge wing in order to show off the self-cure, self-anti-icing and self-sensing materials we have developed.”

Further, according to AMRC, the development of all three technologies centers on the electrically conductive nature of the composite structure, which is vital as the industry moves to more electrified aircraft, with the ultimate aim of one day being fully electric.

“First, self-curing is a new manufacturing technique for these composites. Currently, they are manufactured in an autoclave but they can be slow and expensive to run. Running electrical current through the composite fibers to act as the heating element to cure the component can be cheaper, quicker and uses much less energy. It also complements our work on anti-icing,” says Matthew.

Another disadvantage of using autoclaves to heat composite structures, says Dr Betime Nuhiji, technical lead at the AMRC Composite Centre, is that engineers are limited by its size. “An autoclave produces high-quality parts, but it takes a lot of energy, a lot of time, and you can only create a part that is as big as the autoclave,” Nuhiji says. “The Boeing 787 is manufactured in the biggest autoclave in the world, but it is expensive, not sustainable and not practical to build these huge autoclaves. The team has developed a heating system where a power supply is directly connected to the composite structure and a current is run through it so it heats up, just like a heating element.”

Nuhiji goes on to describe the benefits of using electrical current to heat composite structures, noting that while there are many, the “main ones are low energy output and low equipment costs. There is also the close control of heating, because when you turn an oven off it is still hot, so you are still effectively heating the part; when you turn off the electrical system no more power is going through it.”

Matthew says that similar technology is being used to investigate self-anti-icing: “Currently, aircraft remove surface ice by drawing hot air from the engine to melt the ice, but this takes power away from the engine and is less efficient. Because of this, we have been developing an electrical anti-icing system that doesn’t require separate heating elements in the component.

“Linked to both these technologies is self-sensing, monitoring the electrical resistance of the part to detect damage. When you get barely visible impact damage (BVID), the resistance changes so you can monitor that and detect where the damage is. BVID is something the aerospace industry is very interested in because it is very difficult to detect through visual inspection, which they currently do, on composite structures.”

Matthew adds that, to enable these smart functionalities, it has required some development on behalf of the resin. “Within a composite, the fibers are electrically conductive but the resin is electrically insulating,” he says. “Part of the project to develop these bulk materials is to make the component more conductive by mixing carbon nanotubes into the resin, so that the whole part is conductive, not just the fibers.”

According to Matthew, doing this should enhance every aspect of the MASTRO project. The self-curing and the anti-icing will reportedly perform better because the heat is distributed more evenly, which in turn will enable increased damage detection responses because the entire composite — not just the fibers — is conductive.

However, Betime says, the challenge now is creating panels that replicate how these materials would need to be used in a real-world environment on the leading-edge of an airplane wing.

“At the start of the project we conducted lots of trials on smaller panels to optimize how to detect damage and cure effectively,” he says. “Now we need to upscale; the final demonstrator we want to show is the leading-edge, which is two meters long.”

According to Matthew, the COVID-19 pandemic has meant work on the MASTRO project had to slow down briefly over the summer, but a physical demonstration of the work the AMRC team has been conducting is imminent.

“We started the latest work package at the start of 2020, which was making the two demonstrators — which have slightly different properties — then finishing the design and starting manufacture. We have been delayed but we have now manufactured our first self-curing, self-anti-icing and self-sensing part and can start testing very soon.”

The overall objective of the MASTRO project is to develop intelligent bulk materials, incorporating self-responsive properties that increase consumer safety, component life span and performance, while reducing maintenance and manufacturing costs, and greenhouse gas emissions.

This project was funded by the European Union’s Horizon 2020 research program under grant agreement No 760940, under the project titled MASTRO.

Related Content

JEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreHexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MorePlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreRead Next

AMRC develops 3D woven composite components for fusion nuclear reactor

The University of Sheffield AMRC is developing a ceramic composite breeder blanket capable of withstanding the extreme temperatures in a nuclear reactor.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More