Aerospace

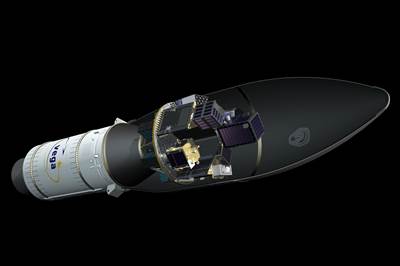

Vega VV16 rocket launches with Bercella composites dispenser structure onboard

The CFRP dispenser structure, developed for the Small Spacecraft Mission Service (SSMS), was successfully launched for the European Space Agency.

Read MoreComposite Factory receives PRI Registrar accreditation

The PRI Registrar recognizes Composite Factory for its commitment to continual improvement in its management system and quality excellence.

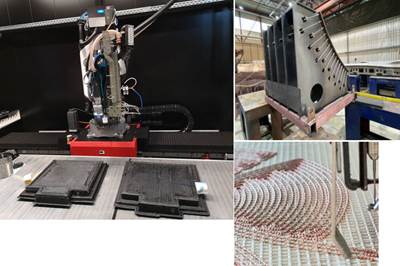

Read More3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

Read MoreCorrection: First CFRP fuselage in Mexico was Stela-M1 trainer

Aeromarmi built an all-composite fuselage before RHEM Composites.

Read MoreRock West Composites receives silver Boeing Performance Excellence Award

The company received the award for consistent performance excellence over a twelve-month period from October 2018 to September 2019.

Read MoreNikkiso, Airbus partner for UltraFan demonstrator project

The project aims to provide nacelle components for the engine UltraFan demonstrator. Nikkiso’s role is to reduce manufacturing costs by a new out-of-autoclave curing method.

Read MoreComposite Bonding & Repair Benefits and Solutions

Film and paste adhesives, wet peel-ply and potting compounds enable the aviation industry to utilize advanced materials that contribute to lightweighting, more efficient designs, and improved sustainability.

WatchHRC invests in new serial production center in China

Developed for the manufacturing of advanced aeronautic composite parts, the production center will be equipped with technologies for both thermosetting- and thermoplastic-based composites.

Read MoreKraibon elastomer improves adhesion and composite material properties

Gummiwerk KRAIBURG’s elastomer product protects against impact, directly adheres to materials, improves damping properties and more.

Read MoreCompoTech launches standard range for carbon finer epoxy beams

Produced via AFP and precision press molded results in a high-strength carbon epoxy composite beam with 10-15% higher stiffness in the axial direction.

Read More