BMI

Open-hole compression testing

By the early 1980s, the emphasis was shifting from development of composite materials to development of tough, durable composite materials. The common catch phrase that emerged was "effects of defects." This new emphasis on toughness dictated the development of test methods that could measure this material

Read MoreComposites take off ... in some civil helicopters

Slowed by certification requirements, composites nevertheless are finding their way into the fuselages and rotor blades of commercial helicopters.

Read MoreAre high-temp thermosets ready to go commercial?

Developed for the U.S. military, these high-performance matrices are branching out into wider use.

Read MoreResin transfer molding and preforms for jet engine stators

New 3-D woven preforms and nanofillers will improve part quality and reduce manufacturing costs.

Read MorePost-show review of the 2004 U.S. SAMPE Symposium

Largest-ever Symposium serves up a large helping of news and new technologies from advanced composites suppliers.

Read MoreGENOA modeling software closely predicts composite structuralfailure

Progressive failure analysis and material-level damage modeling enable life prediction of composite structures.

Read MoreNacelle manufacturers optimize hand layup and consider closed molding methods

Focused on optimizing traditional hand layup, nacelle and thrust reverser manufacturers cast an eye on future use of automation and closed molding.

Read MoreComposites combat ready in UCAVs

As unmanned aircraft are designed from inception for combat duty, composites will carry the payloads in structural components.

Read MoreFiber Placement The Centerpiece Of NCAM

Cryogenic composites just one facet of Lockheed Martins National Center for Advanced Manufacturing.

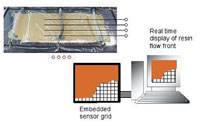

Read MoreLiquid Composite Molding Achieves Aerospace Quality

Improvements in materials, tooling and process control bring RTM and VARTM into the realm of aerospace components.

Read More