Nacelle manufacturers optimize hand layup and consider closed molding methods

Focused on optimizing traditional hand layup, nacelle and thrust reverser manufacturers cast an eye on future use of automation and closed molding.

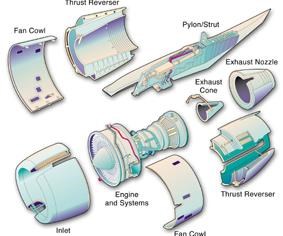

The smooth shape of an aircraft nacelle, the structure that surrounds the jet engine, belies its underlying complexity. While providing an aerodynamic shell for minimum drag, a nacelle also incorporates deicing capability, noise attenuation and mechanisms to reverse engine thrust for braking. First conceived and manufactured in the mid-1970s, composite nacelles are designed for lower weight to provide better engine fuel economy and, more importantly, to attenuate engine noise to meet increasingly stringent airport noise regulations. Today most commercial aircraft - particularly those with long-range capability - are outfitted with composite nacelles.

Nacelles and thrust reversers are big business: total market size is about $2.8 billion annually, including commercial transports, business jets and general aviation aircraft, according to Nigel Barker, director of research and development at Goodrich Aerostructures (formerly nacelle pioneer Rohr Inc., Chula Vista, Calif., U.S.A,). Research firm Jane's Information Group cites a current demand of about 1,000 nacelles annually for Boeing and Airbus aircraft. Major manufacturers include Goodrich Aerostructures; The Boeing Co. (Wichita Division, Wichita, Kan., U.S.A.); NORDAM Group (Tulsa, Okla., U.S.A.), GKNAS (formerly GKN Westland Aerospace, St. Louis, Mo., U.S.A. and Isle of Wight, U.K.); Vought Aerospace (Dallas, Texas, U.S.A.); Middle River Aircraft Systems (MRAS, Baltimore, Md., U.S.A.), a division of General Electric; and Hurel Hispano, a new division of Snecma Group (which includes former bizjet nacelle maker Hurel Dubois). Hurel Hispano makes nacelle structures for Airbus (Meudon-la-Foret Cedex, France). A large number of smaller firms manufacture spares and replacements under U.S. Federal Aviation Admin. (FAA) type certificates.

Here, HPC gets under the skins of these complex structures and, in conversation with three of the top nacelle manufacturers, sees what fabrication strategies may lay beyond traditional layup.

Nacelles in a nutshell

In simplest terms, a nacelle is analogous to the hood of a car. Cylindrically shaped, the nacelle forms the outer, aerodynamically smooth covering for a jet engine. The nacelle wraps around and encases the engine - wider at the front or inlet and narrower at the back or aft end. By way of background, a jet engine takes air in through the inlet. Part of that air is compressed and burned in the combustion chamber and expelled as high-velocity exhaust jet. A larger amount of air bypasses the combustion process, pushed rearward by a high-velocity, internal fan like a propeller through a bypass fan duct. The bypassed air mixes with the hot core exhaust to gain overall thrust with less expenditure of fuel and with less noise.

The forward one-third of the nacelle, termed the inlet cowl, is the smoothly contoured opening that directs air into the engine's fan and compressor blades. While the inlet is primarily composite, the leading edge, referred to as the lipskin, is often metal because of the potential for damage from ground vehicles or debris kicked up during landings. The inlet cowl typically has a built-in de-icing system, heated by hot air from the engine to prevent ice buildup. Making up the middle third is the fan cowl, the cylindrical sleeve that covers the fan and compressor as well as the combuster portions of the engine. This cowling typically features two, three or more hinged panels that can be raised for engine inspection and maintenance. A number of small access doors are cut into the cowling, to facilitate visual inspection of key engine components as well.

The aft third and most complex, highly loaded part of the nacelle is the thrust reverser. As its name implies, the thrust reverser redirects the flow of the jet engine's exhaust and/or bypassed air from backwards to forwards to decelerate during landing or rejected takeoffs.

There are two general types of thrust reversers: 1) "buckets" or "target reversers" that open like a clamshell to block both the engine core exhaust and the bypass air and redirect them forward, or 2) "cascade" type reversers, in which large panels ("transcowls") translate backwards, exposing an open grid or cascade through which only the bypassed air is redirected. Buckets are typical on business jets and commercial aircraft fitted with fuselage-mounted engines, like the McDonnell Douglas MD-80, while the cascade type are found on underwing nacelles, such as Boeing's 737, 747, 757, 767 and 777.

Composites are selected for nacelles for several reasons: the most obvious being weight, says Kevin Jackson, technical sales manager of NORDAM Nacelle/Thrust Reverser Systems Division of the NORDAM Group. "Most business jets have a rear-mounted engine, as far back from the center of gravity as you can get. By making the engine nacelle and thrust reverser lighter, it not only saves weight at the engine location, it saves overall aircraft weight, because you don't have to add as much weight in the nose to balance the plane," explains Jackson.

The nacelle, and particularly the thrust reverser, has to be strong enough to withstand air loads during flight and braking, but, according to Jackson, "If we make it stiff enough to resist deflection, typically it will be strong enough for those loads." Eccentric loads are even more important, says Goodrich's Barker. "If the engine loses a fan blade, the unbalanced fan creates forces in the inlet worse than anything you'd see in flight," he says. "You also have to consider shock loads, which could occur if, for example, a line ruptures in the engine, as well as acoustic vibration fatigue and rejected take-off air loads. Nacelle design is really a tradeoff among a number of different performance requirements."

Temperature resistance is yet another design driver, especially for thrust reversers. The cooler bypassed air tends to insulate the nacelle and thrust reverser panels from the hot core exhaust flux, making high-temperature (177°C/350°F cure) epoxies an appropriate choice, as long as components in the immediate vicinity of the engine are protected with insulation, says Boeing's Mike Borgman, of the stress engineering group at Wichita's Strut, Nacelle & Composite Responsibility Center. "But, even with our insulation protection, we're close to the service threshold for epoxy. We would, of course, like to get rid of the weight and expense of the insulation. A composite resin system with a service temperature even greater than BMI [bismaleimide] is required. Polyimide and high-temperature oligomers offer potential, but material costs and processing difficulties currently limit their use - but we're always looking for materials with higher service use temperatures." Adds John Welch, associate technical fellow at Wichita, "Research entities like NASA are continuing to advance material systems."

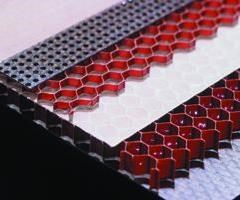

Increasing pressure to reduce aircraft noise has driven manufacturers to incorporate sound attenuation characteristics into nacelle and thrust reverser structures. While some panels and smaller access doors are solid laminates, the majority of the parts are structural cored sandwich panels, specifically designed to absorb acoustic energy yet strong enough to transmit loads between the engine and the aircraft. The inner panel skins that are in contact with engine airflow are perforated with thousands of holes, typically in the range of 1 mm/0.04 inch in diameter. The perforations help to attenuate the jet engine's noise by damping the energy response, directing the sound into the honeycomb core, rather than presenting a hard surface that simply deflects the sound. Most suppliers add a perforated inner septum or porous layer to the honeycomb core, effectively doubling the number of cells, for greater noise suppression and a wider range of attenuated frequencies. Cores are "septumized" using a variety of proprietary methods, such as dipping the core in resin or sandwiching material between two or more honeycomb layers.

Nacelles are complex assemblies of multiple curved panel components, of varying thickness, that are fitted together to encase the engine. Manufacturers typically hand lay up the panels, in both female and male molds. For example, the cascade-type thrust reverser for the Boeing 777 is made up of a smooth outer sleeve (ultimately painted), which can be either a sandwich panel or a solid laminate with rib stiffeners; an inner acoustic lining sandwich panel as described above; and a smaller inner wall assembly that conforms to the engine combustion chamber. The gap between the inner wall and the outer/acoustic panel forms the duct for the bypassed air. All components are fitted with a combination of composite and metallic connectors that enable attachment to the engine. In addition, the panels also support hydraulic hoses, electrical and air lines related to the engine's function. A metal mesh is typically included in the outer sleeve's laminate for lightning strike protection. The engine is bolted to a pylon structure or strut, which is part of the aircraft's structural airframe, and the nacelle panel is shaped to fit around the pylon.

Design and manufacturing efficiencies streamline hand layup

Boeing is both a buyer and fabricator of nacelles. While many components for its commercial aircraft, including some nacelle components, are subcontracted to Tier 1 suppliers, Boeing's Wichita Division fabricates and assembles nacelle components, for the 747, 757 and 767 aircraft, and thrust reversers for the NG737 (next-generation) and 777 models. The company takes an established approach to nacelle fabrication, using standard qualified materials, but adding innovative twists.

Doug Scott, director of NG737 and 777 thrust reversers, says the Wichita group makes parts for thrust reversers that accommodate all of the "big three" jet engine suppliers - General Electric, Pratt & Whitney and Rolls Royce. "We have a history with metals, but in terms of composites, we're coming down the curve and are competitive with metals on a cost basis - we practice lean manufacturing and have partnered with our suppliers to reduce our costs and cycle times."

Composite nacelle assemblies have been designed for fast manufacturing, says Welch, accomplished by consolidating to achieve the lowest part count while minimizing part complexity. Current transcowl assemblies integrate a large number of parts that existed as separate assemblies on prior designs. "Our NG737 and 777 transcowl designs have reduced part count by 66 percent, while reducing weight by 25 percent and assembly time by 22 percent," says Welch. The hand layup process has been streamlined as much as possible. A dedicated material cutting and kitting area is outfitted with several automated cutting tables that prepare part kits as needed. The kits are packaged and delivered to technicians, who lay up the materials in metal Invar molds, both concave and convex. Materials come from "typical suppliers," says Scott, whose materials are qualified on most Boeing aircraft programs. Laser projection systems from Laser Projection Technologies Inc. (Londonderry, N.H., U.S.A.) enable efficient ply placement.

Boeing Wichita produces its own tools in-house for the nacelle parts. "Our current tendency is to use Invar tools," says Borgman. "They offer a life-cycle advantage compared to carbon composite tools, and also provide a more uniform cure temperature profile over the component surface area. We've found that's very important for consistent part quality when curing large components in a large autoclave."

Scott notes that one of his company's manufacturing innovations is dedicating a tool to each part throughout the manufacturing process - from fabrication to cure to final machining, the part stays in one tool until finished. "We can control part variation with this procedure," says Scott. "By breaking a part out of a layup tool and placing it in a different milling fixture, you can induce variation."

Boeing's nacelle panels incorporate patented innovations for noise suppression that have been developed over time by the Wichita group. The group uses a proprietary method to form the acoustic perforations in the panels' inner skins. "We mold the holes in the sandwich facing skins during cure, which makes them stronger compared to other methods like drilling, with a resulting weight advantage," says Welch. A variety of core materials are used, including aluminum, fiberglass and pitch-based carbon fiber. Boeing's acoustic septum is inserted in a proprietary process that involves laser drilling to produce the holes, effectively doubling the number of cells.

Borgman points to the company's expertise in producing very thick sandwich structures for thrust reversers, which provides room for the "blocker doors" to nest when not deployed. (Blocker doors are the inner panels that block the bypass air, directing its flow through the cascade.)

"We provide a pocket for them to fold into by stacking a thicker core (more than 3 inches) on a thinner core (about 1 inch) separated by an intermediate laminate," explains Borgman. "We then machine the thick core down to the laminate, to form the pocket." To address raw honeycomb edge issues, Borgman says that edge closeout material is added during fabrication so that no edge dressing is required after final panel machining. He notes that the 76 mm/3-inch thick honeycomb can be formed to contours as tight as 1.1m/44-inch radius curves.

Repair of nacelles is a huge consideration, especially for aircraft with engines mounted below the wings and vulnerable to damage. The round fan cowling and thrust reverser panels are made in segments (halves, thirds or even quarters of the total circumference) allowing easy removal of the damaged segment. But, says Borgman, the tradeoff is more seams, which can cause aerodynamic disruption. To ensure minimal aero drag, sub-structure support and structural joints that support the nacelle are engineered with tight tolerances. Scott notes that the company is working with Wichita State University's National Institute of Aeronautical Research (NIAR) on continuous improvement of repair technology. In addition to collaborative repair research efforts with NIAR, the FAA and other entities, Boeing has developed repair kits for fleet customers, which, with support from Boeing company personnel, have enabled repairs in the field in a matter of days. The Boeing Wichita facility is an FAA-certified repair facility that, on average, repairs 200 nacelle components per year.

"The diameter of a 777 nacelle is about the same as the fuselage diameter of a 737," says Scott. "We've made hand layup a good solution, but as we move toward the 7E7, we're looking at automated methods." The company also is investigating new resins and additive materials to increase high-temperature performance, such as the addition of phosphorous amides to polyimides for extreme heat situations.

A legacy of nacelle design

Goodrich Aerostructures comes to the nacelle and thrust reverser market through its acquisition of aircraft part manufacturer Rohr Inc., the first to produce a commercial composite nacelle. Goodrich supplies complete nacelles for Airbus' A300, A310, A320 and A340 and Boeing's 717. The company also makes nacelle components for Boeing's 747 and 767, and produces the inlet cowls and fan cowls for the 737NG. Most recently, the company was selected to provide nacelles for a new Japanese military cargo plane, the C-X. "For longer-range aircraft, the designs are driven to composites for weight and other advantages, like resistance to corrosion from deicing fluids," says Barker.

Like other suppliers, Goodrich uses standard engineering design tools, including CATIA from Dassault Systemes (Woodland Hills, Calif., U.S.A.), NASTRAN and PATRAN for structural analysis, and internally developed codes for laminate design.

The company's acoustic panel structures, branded as DynaRohr, are made in a unique fabrication process, says Barker. Goodrich perforates the carbon fiber/epoxy face skins of its nacelle and thrust reverser sandwich panels with an "erosion" technique called NPT (New Perf Technology). The method places a perforated sheet over the selected honeycomb material, (aluminum, fiberglass, aramid or titanium). A proprietary blasting medium propelled by compressed air is used to creates the holes. To make the septum within the core, Barker says that a very fine areal weight woven mesh is "bonded into the core blanket" to create a double cavity within each core cell. "Our DynaRohr acoustic panels have been shown in testing and through modeling to suppress a wider frequency range of sound than other designs," he maintains.

Barker's group is constantly searching for new materials and manufacturing methods. While most fabrication is hand layup in Invar tools, the company investigated has investigated filament winding for improved efficiencies. Today, Goodrich is experimenting with liquid molding techniques, including resin film infusion (RFI) and resin transfer molding (RTM), to drive down costs, based on some successful prototype parts built for NASA's reusable space launch vehicles. A proprietary method of sealing honeycomb core material against resin ingress has been perfected so that the core can be used in the RTM process, says Barker. "A new manufacturing method is hard to introduce into existing programs. We're currently making small access doors and other small parts to gain acceptance."

On the materials side, the company has investigated the use of high-temperature polyimide resin for the inner panel of a thrust reverser and engine core cowl. These included both honeycomb sandwich acoustic structures and hollow, hat-stiffened, solid laminates. Temperatures in that area, close to the engine core and jet exhaust, can reach 315°C/600°F, and the parts are traditionally made with aluminum panels or carbon/epoxy protected with insulating blankets. When flight-tested for more than 5,000 hours, the carbon/polyimide part "microcracked badly," says Barker. "But we're continuing the search for composites that can take those kinds of service temperatures."

Goodrich, a member of the Commercial Aircraft Composite Repair Committee (CACRC), includes "repair schemes" with all of its products, says Barker. "We have an extensive product support network, including representatives to the airlines and structural repair manuals to help facilitate needed repairs. Of course, we can do larger, custom repairs at our facilities in the U.S., Europe and Asia," he says. CACRC airline operator members are advocating a single repair material and streamlined procedures, and progress is being made toward that goal, reports Barker.

The bizjet market

At the other end of the spectrum, NORDAM is the largest manufacturer of nacelles and thrust reversers for business and small jets, as well as a major repair facility. Customers include Cessna, Dassault, Gulfstream and Bombardier. The company makes many types of nacelle components, some all-metal, some metal/composite and some all-composite.

NORDAM makes its parts in open Invar production tools, using 177¡C/ 350¡F cure carbon/epoxy prepregs supplied by Cytec Engineered Materials Inc. (Tempe, Ariz., U.S.A.) and Hexcel (Dublin, Calif., U.S.A.). Invar tools are preferred because of the relatively high production rate and large number of parts produced each year. Jackson reports that the company uses an automated cutting and kitting table from Gerber Technology Inc. (Tolland, Conn., U.S.A.) to prepare material kits for layup. FiberSIM laminate design software from VISTAGY Inc. (Waltham, Mass., U.S.A.) interfaces with the company's CATIA design programs and a Virtek Laser Systems Inc. (Waterloo, Ontario, Canada) laser projection system, to facilitate layup in the molds.

All composite nacelle and thrust reverser parts are cured in the company's two large production autoclaves. After post-cure, the inner skins of the acoustic sandwich panels are drilled in a customized jig to produce the holes that align over the honeycomb core, for noise suppression. At the current time, says Jackson, the company does not add a septum to the core.

NORDAM is close to introducing a new thrust reverser product, made with carbon fiber/BMI prepreg and a fiberglass honeycomb core. "Our epoxies have a hot/wet service temperature of about 138°C/280°F," says Jackson. "With the BMI, we can go quite a bit higher." Despite significantly higher cost for BMI prepregs, the new thrust reverser saves 400 lb per aircraft compared to the metallic part that it replaces, which will translate to overall aircraft cost savings in the long run.

NORDAM is somewhat unique in the industry in that it has an active engine and thrust reverser test facility, capable of not only measuring engine thrust levels up to 24,000 lb but also testing installed nacelle and thrust reverser components. Says Jackson, "Thanks to our location in the country, so far we haven't had noise restrictions imposed upon the facility." The test pylon can measure pressure, temperature, strains and vibrations on nacelle components and can determine static noise levels in compliance with FAA requirements.

The company also is FAA-certified to perform repairs and maintains facilities at its Tulsa headquarters and in Singapore and South Wales, U.K. as well. NORDAM also maintains ties with NIAR's repair and material certification programs, and is currently in the process of using NIAR's testing laboratory to qualify composite materials.

With optimized hand layup, nacelle manufacturers are producing very high-performance parts designed for multiple performance requirements, but automation and advanced high-temperature materials are likely options.

Related Content

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More