CAMX

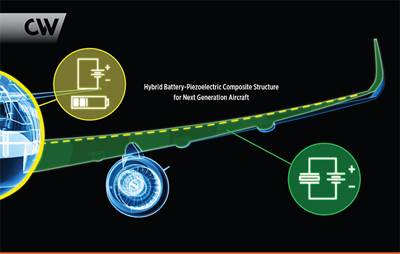

Aerocomposites: The move to multifunctionality

Designers envision aircraft components that do more than bear structural loads, but must first confront great complexities to actualize greater functional efficiency.

Read MoreCAMX Exhibit Previews: Part 2

CAMX 2015 is less than a month away (Oct. 26-29, Dallas, TX, US). If you're going to the show, or thinking of going, you might want to know a little about what will await you on the exhibit hall floor. CompositesWorld asked CAMX exhibitors to send previews of the products and technologies they'll have on display. Here is Part 2 of the response we received.

Read MoreCAMX Exhibit Previews, Part 1

CAMX 2015 is less than a month away (Oct. 26-29, Dallas, TX, US). If you're going to the show, or thinking of going, you might want to know a little about what will await you on the exhibit hall floor. CompositesWorld asked CAMX exhibitors to send previews of the products and technologies they'll have on display. Below is Part 1 of the response we received. Simply click on the company name to see what it has in store, and look for Part 2 in the next CAMX newsletter.

Read MoreKeynote Q&A: Gary Smyth, GM Global Research & Development

Gary J. Smyth, Ph.D., executive director, Global R&D Laboratories, GM Global Research & Development, will be the keynote speaker at CAMX 2015 (Oct. 26-29, Dallas, TX, US), discussing the carmaker's material and manufacturing strategies as it pursues lightweighting in new-car development. CompositesWorld offers this Q&A with Smyth, as a preview to the live event, Tuesday, Oct. 27, 9:00-10:30 a.m.

Read MoreResins for the Fast Zone

An automotive supplier must have the ability to produce a composite part in a minute, or at least in minutes — not hours or days, the norm for composites in most other industries. Meeting that part-per-minutes goal is a huge hurdle that a few composite fabricators have cleared, and many more are involved in development efforts, with OEM or Tier partners. CompositesWorld reviews how resin suppliers have evolved their products for this critical market.

Read More3D Printing Moves Into Tooling Components

Some pundits predict that 3D printing, or additive manufacturing (AM), will change our world forever. While that may yet be, one thing is clear: The growth of 3D printing over the past two decades has wrought significant change in composites tooling. Although AM’s most obvious advantage is direct part production without tooling, the growing trend in the aerospace and automotive sectors at present is its use for fast, on-demand builds of mold tools to keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

Read MoreHP-RTM on the rise

Decades of development have propelled it to prominence but its future demands industrial solutions for handling cost, complexity and process control.

Read MoreComposites in commercial aircraft engines, 2014-2023

The drive to boost aircraft operating efficiency continues to fuel adoption of polymer matrix composites in jet engines.

Read MoreA critical market sector: Downhole composites in oil and gas

Tremendous secrecy and non-disclosure has kept this profitable composites application out of the spotlight, while it has enabled the current shale oil energy boom.

WatchCAMX Panel Sheds Light on Monomer-free Sheet Molding Compound

Sheet molding compound (SMC) has had a long but not always happy history in the automotive industry, but it's being challenged by concerns over styrene emissions. An expert panel at CAMX 2014 evaluated the potential of a monomer-free future for SMCs.

Read More

_500.jpg;maxWidth=400;quality=70)

.jpg;maxWidth=400;quality=70)

.jpg;maxWidth=300;quality=90)