Aerocomposites: The move to multifunctionality

Designers envision aircraft components that do more than bear structural loads, but must first confront great complexities to actualize greater functional efficiency.

Much has been written in these pages about the pressing need to reduce commercial air carrier fuel costs and CO2 emissions by lightweighting aircraft through the use of composite materials. The next wave in this movement is almost certain to be multifunctional composites. What are they? Composite laminates that not only provide lightweight, load-bearing structures, but also perform additional functions. Structural health monitoring is the most developed example of such a function to date, and was explored in CW’s August issue (see “Structural health monitoring: NDT-integrated aerostructures enter service,” under "Editor's Picks" at top right). But there are many other potential functions, among them thermal and/or electrical conductivity/storage, impact resistance, acoustic damping and, eventually, self-healing and morphing or shape-changing.

Multifunctional composites spring from at least two stimuli. The first is biological structures, the observation of which has spawned an engineering practice called biomimicry. “All natural materials are multifunctional,” asserts Sathiskumar Ponnusami, a Ph.D student at Delft University of Technology (TU Delft, The Netherlands) and the leader of a team called MultiFun, which has designed an aircraft wing that integrates piezocomposites and battery (energy-storage) composites to harvest vibrational energy, convert it to electrical energy and store that energy for use in local subsystems, eliminating the need for external batteries and cabling.

The second stimulus is the current lack of functions, such as electrical conductivity, in fiber-reinforced polymers that are inherent in legacy aircraft metals. “The weight benefits of composites are being compromised by having to add extra layers,” explains Tamara Blanco, research & technology airframe materials engineer for Airbus Operations (Getafe-Madrid, Spain). For example, metal mesh/foil must be added to the surfaces of composite airframes to meet lightning strike requirements, notes fellow Airbus airframe engineer Enrique Guinaldo, “but it would be better to incorporate the metals into the laminate.”

For Dr. Dineshkumar Harursampath, head of the Nonlinear Multifunctional Composites Analysis and Design (NMCAD) lab, Department of Aerospace Engineering at the Indian Institute of Science (Bangalore, India), the key question is, “At what scale are you integrating multiple functions and materials?” The potential benefits increase, in fact, as the level/scale decreases — from macro to micro to nano. However, as multifunctional composites advance down the geometric scale, the level of complexity increases, as do the challenges.

Stepwise approach to multifunctional airframes

There are two basic approaches to the task of creating multifunctional composites. “You can combine different materials via layers or modify the building blocks/components of the materials themselves,” says Blanco. The former is easier, and there is debate in the multifunctional research community as to whether the result can even be called a true multifunctional composite. And yet, that is the basis of Blanco’s and Guinaldo’s patented “Multifunctional Composite Material Including a Viscoelastic Interlayer” (US 2014/0011006 Al). Modifying the building blocks is preferred because it produces greater benefits, but it will also take longer, Blanco explains, “because we must fully characterize, qualify and certify these new structural materials.” Thus, the two engineers see their patented technology as a first step, enabling progress in the near term because some of the laminate’s constituents are already qualified for use on aircraft.

Complicating the pursuit of multifunctionality in either approach is the inevitability of trade-offs. “The idea was to have a structure that can withstand high-energy impacts (3,000J), for example, from ice shedding,” Guinaldo notes, “but also be capable of acoustic damping to reduce noise entering the cabin from engine-derived high-frequency vibrations.” The team began by embedding viscoelastic rubber materials into the laminates, but despite optimization of parameters, Guinaldo recalls, “we found out that mechanical properties decrease due to the lower stiffness of elastomeric materials vs. the carbon fiber composite, thus acting as a defect between the structural plies.”

The team also is pursuing use of thermoset resin doped with graphene, CNTs, carbon particles or metallic particles and fibers modified at the molecular level. “We are trying to incorporate nanoparticles in aircraft structure so that we have electrical conductivity through and between components in order to withstand lightning strike events,” says Guinaldo. “Right now, a metallic bonding network must be used, which adds weight, complexity and manufacturing cost.”

Blanco asserts that multifunctional materials are mandatory enablers for integration of cabin, systems and airframe to save weight — for example, structural parts with built-in electrical systems/electronics. “We are progressing here,” she says, but there are challenges including manufacturability, repair and maintenance. Blanco stresses that working with material suppliers is critical, “because if we cannot scale up, then we are not interested in the technology. The materials also have to be affordable. If we increase functionality but also weight and/or cost, it will be difficult to make the business case.”

Guinaldo explains that with the patent’s “first-step” approach, “we can adapt the manufacturing process to meet the tolerances and quality level required, but this becomes more difficult with each functionality you attempt to incorporate. Thus, we must focus on which areas need which functionalities.” He notes some areas need electrical conductivity most, while elsewhere, anti-erosion and anti-icing are more critical. “We want structures that work well for all needed functions: electrical, noise/acoustics, anti-erosion — which we do with coatings that can be mixed with anti-impact solutions — anti-icing and fire barriers,” says Blanco, adding, “And, in the long term, we will need to combine different functionalities for specific applications. We are also looking at sensing capabilities, while other capabilities such as morphing are interesting for lift and control devices/surfaces.” But she acknowledges many of these are still decades away and “you have to find the right balance between gaining functionality and sacrificing other properties.”

MultiFun’s hybrid composite

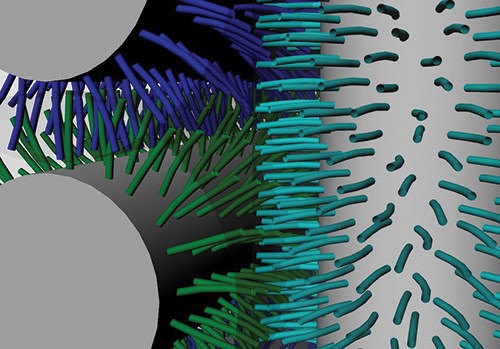

The Ponnusami-led MultiFun team’s “Hybrid Battery-Piezoelectric Composite Structure for Next Generation Aircraft” project is an example of the “building blocks” approach — integrating energy harvesting and storage into wing structures. Winner of the fourth biennial Airbus Fly Your Ideas competition, Ponnusami explains, “The unique aspect of our design is that we combined the piezocomposite and the battery composite into a single, hybrid material.” Combining two different fibers in a single laminate with the same epoxy matrix, the hybrid is able not only to harvest vibrational energy but also to store it as electricity and then release it later for use. “Typically, piezoelectric materials are used in the form of thin plates along with electrodes on the tops and bottoms of structures, creating small electrical currents from dynamic deformations,” says team advisor Harursampath of NMCAD. “But this is inefficient. Just as composites’ anisotropy offers load-carrying optimization vs. metals, if we make piezoelectric materials into a fiber form, they have much larger sensitivity and/or actuation authority along the fiber, which translates into higher efficiency.”

How much energy can be “recycled”? Ponnusami responds, “It’s not a huge amount, but enough to power the numerous low-power electrical subsystems on the wing.” The group calculated a possible 5% fuel savings for an intercontinental flight, based on wing and fuel usage data for various aircraft. He notes that aircraft in general are moving more toward electric power, such as the Airbus E-Fan: “In this aircraft, we see huge benefits for the structure doubling as battery, saving as much as 20% in weight.”

Although the approach has been demonstrated virtually through computer analysis and design calculations, Ponnusami admits, “There are a lot of challenges we must face in order to realize an actual part.” One is that the piezocomposite and battery composite materials are relatively new, with the latter not yet commercially available. “It is not just a part you have to design and build, but also the electrical system that enables charging and then discharging to a device,” he adds. An interfacing circuit/medium must exist between the harvesting piezocomposite and the charging/discharging battery composite, which adds another manufacturing complexity. The structural properties of this new hybrid composite also must be matched to ensure that the overall design has sufficient load-carrying capability. “We know the density of these multifunctional materials is higher,” explains Ponnusami, “but you are storing energy in the structure now, so you no longer need batteries and cabling. All of this should balance, but the optimization and tailoring work to make sure the wing design is not compromised still needs to be completed.”

The team, now spun off as a company of the same name, has patented several of the technologies and plans to build demonstrators based on them in 2016.

Functionalized Interleaf Technology

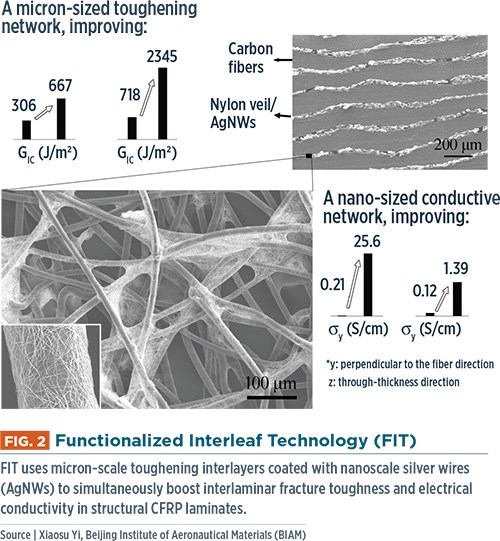

Dr. Xiaosu Yi at the Beijing Institute of Aeronautical Materials (BIAM) has demonstrated a micron-sized toughening network for laminates via polyamide interleaving, adding silver nanowires (AgNWs) to boost electrical conductivity. At the 19th International Conference of Composite Materials (ICCM-19, Jul. 28-Aug. 2, 2013, Montreal, QC, Canada), Dr. Xiaosu Yi presented “How to Make Structural Composites Multifunctional,” highlighting his research team’s developments in Functionalized Interleaf Technology (FIT), improving both electrical conductivity and impact damage resistance of carbon fiber-reinforced polymer (CFRP) composites for aircraft applications. “My group is pursuing a three-step strategy,” says Yi. “First, improve the impact damage resistance of high-performance structural composites; second, integrate multifunctionality; and third, make composites sustainable.”

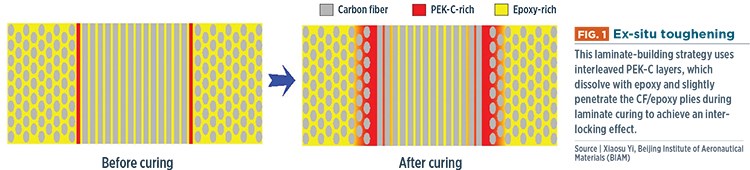

As part of step one, Yi’s team has developed Ex-situ toughening, which interleaves 10- to 20-μm thick layers of solid phenolphthalein polyetherketone (PEK-C) — an amorphous thermoplastic with properties similar to polyetheretherketone (PEEK) — in a structural CFRP laminate. “Our goal was to increase the out-of-plane properties without sacrificing any in-plane properties,” says Yi. “This is why the polymer interlayers must be just thick enough to provide toughness but not compromise the carbon fiber volume fraction.” Yi explains that the achievement of Ex-situ toughening is to manage the conventional time-temperature processing parameters to control the interlaminar structure and diffusion depth of the thermoplastic to achieve an interlocking effect with the CF/thermoset plies (see Fig. 1, at left). Test results show this technique works well with epoxy, bismaleimide, polyimide and benzoxazine, as well as in prepregs for autoclave or preform-based liquid molding, such as resin transfer molding (RTM).

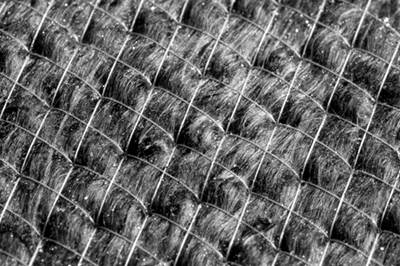

FIT, a step two initiative, uses perforated PEK-C film or polyamide veil as interlayers, coating them with 70-nm-diameter AgNWs for a tailored areal density of roughly 1.18 g/m2. The AgNWs form a densely interconnected web (see lower left image in Fig. 2, at left) across the interlayer surface and even across the thickness at the edge of the perforation holes. Thus, two interdependent network structures — the interlayers at the micron scale and the nanoscale AgNWs — coexist to provide substantial improvement in both interlaminar fracture toughness and electrical conductivity.

“For electromagnetic interference shielding and particularly for lightning strike protection, the biggest challenge is to significantly increase the through-thickness electrical conductivity,” says Yi, “because the polymer-rich interlayer is electrically isolated in the laminate.” He notes that modern airframes require a through-thickness electrical conductivity higher than 10-20 S/m (Siemens/meter is the SI unit for conductivity), but the best commercially available structural carbon composites show only 2 S/m. Notably, FIT has produced structural laminates with 139 S/m.

Yi notes that the patented Ex-situ and FIT technologies are both fully compatible with current industrial aerospace manufacturing, which should reduce the risk of inserting these technologies as well as the time and cost of scale-up. In fact, a specific collaboration was established between BIAM and Airbus last year to prove the capability and potential of this technology for Airbus composite material systems.

Aligned CNTs and nanostitching

Pontus Nordin is a technical fellow in aircraft design, airframe technology and systems integration at Boeing/Airbus Tier 1 partner Saab AB (Linkoping, Sweden). He also is one of the inventors of Saab’s patented multifunctional anti-icing/de-icing system, which he notes is the company’s first use of truly multifunctional nanocomposite structure.

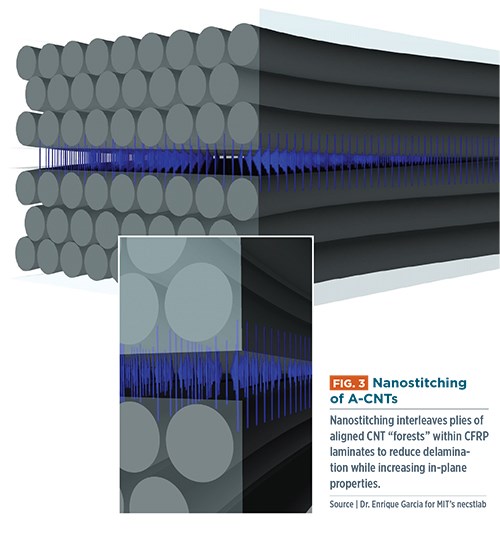

Nordin has worked with Dr. Brian Wardle and his Nano Engineered Composite Aerospace Structures (NECST) consortium’s “necstlab” research team (see “The end of delamination?” under "Editor's Picks") at the Massachusetts Institute of Technology (MIT, Cambridge, MA, US) to develop aligned carbon nanotubes (A-CNTs) and nanostitching, which improves laminate damage resistance and mechanical properties, while Saab’s graphene-based de-icing aerostructure is very close to flying.

“Typically, if you want this function, you add metal layers to generate resistive heat,” he explains. “However, it’s often very challenging to combine carbon fiber composites with metals because of mismatch in CTE and other properties.” Instead, Saab is using CNTs and graphene. “They are much more compatible with carbon fiber than metals, ceramics or even epoxy,” says Nordin, “and we can also tailor the electrical conductivity in the resulting composite.”

The A-CNTs are grown as aligned “forests” on a substrate (see Fig. 3, at left). “You dope a substrate, put it into an oven, introduce a carbonous gas and increase the temperature,” Nordin explains. “You then grow the A-CNTs to a predetermined height, based on process parameters.” The A-CNT forests can be released from the substrate and placed onto a prepreg surface either locally or globally. Conventional composite fabrication processes are then used to impregnate the dry A-CNT forests with the prepreg resin.

(MIT/Saab work published in 2012 detailed how vertically aligned carbon nanotubes (VACNTs) improved CFRP laminates. See the Side Story titled “VACNTs boost macro-properties,” at the end of this story or click on its title under "Editor's Picks").

But is this technology commercially viable? Nordin claims that when fabrication is scaled up, CNTs can be produced more cheaply than carbon fiber. He believes that demand will ramp gradually as the materials are slowly introduced, first into non-flight-critical applications to address specific weaknesses. This matches well the scale up he already sees at suppliers with which he works.

When will the patented graphene multifunctional de-icing wing structures fly? “It continues to take time,” responds Nordin, “because of the conservative nature of the aerospace industry and the requirements for qualification and certification.” His team has proven the technology through ground demonstrators in realistic conditions, and completed significant testing to confirm the most critical material and structure properties early in the development process. “But qualification is a tedious, expensive process. It is more an economic challenge now vs. a technical one.”

Multifunctional, macro-scale CNT fibers

Dr. Juan José Vilatela, has demonstrated composites that produce electricity from vibration, but using a macro-scaled CNT fiber, already being produced in commercial quantities. “Making materials multifunctional requires very good control of where they are and how they interact with each other,” says Vilatela. “This can only be done by building from the bottom up: small-scale to large-scale.”

A researcher in the Multifunctional Nanocomposites Group at IMDEA Materials(Madrid, Spain), a non-profit research institute funded by Madrid’s regional government, Vilatela also eschews mixing nanomaterials into resin to achieve multifunctional composites. “It is not a very efficient route,” he explains. Instead, he works with a macro-scale fiber made from carbon nanotubes, which has a unique combination of mechanical, electrical and thermal properties. “The fibers we use can be made from methane — essentially, natural gas — as the carbon source, so the process is intrinsically cheap, yet we can make kilometers per day.”

Comprising bundles of aligned CNTs, these porous, yarn-like fibers have a diameter similar to carbon fiber, strength and stiffness comparable to aramid fiber and very high electrical and thermal conductivity (see Table 1, at left), yet with a large surface area (10,000 times more than carbon fiber) for energy storage and transfer. “We chemically engineer the interfaces to control the properties of the final composite.” These CNT fibers also show much higher resistance to bending stress than carbon fiber and are easily woven into fabric.

Invented by Alan Windle’s research group at the University of Cambridge (Cambridge, UK), this direct spinning CNT fiber process has been scaled up by spin-off company Q-Flo Limited (Nottingham, UK) and TorTech Nano Fibres Ltd. (Sasa, Israel), a joint venture formed with lightweight armor supplier Plasan (Sasa, Israel). Nanocomp Technologies (Merrimack, NH, US) also produces continuous CNT fibers, as well as tapes and 4-ft by 8-ft sheets that are in commercial use by an impressive list of customers. “Qingwen Li’s group in China has demonstrated producing electrical energy from vibration using these materials, which are excellent at collecting energy on a molecular level when paired with a piezoelectric or photovoltaic material to convert the energy,” relates Vilatela. The IMDEA group is modifying the material’s structure to optimize not only electrical charge transfer but also charge storage. “In principle, our nanofiber materials can perform electrical, energy storage/transfer and mechanical functions simultaneously,” says Vilatela.

The group already has produced device demonstrators, but the materials are far from ready to form aircraft wings. “We still need to improve mechanical properties,” Vilatela acknowledges. “Making something that can harvest energy is easy. Making it structural as well is not.” However, current mechanical properties might be in line with secondary structure expectations or other composite markets. Aircraft interior components, for example, are already being developed to use recycled carbon fiber (see “Recycled carbon fiber update: Closing the CFRP lifecycle loop” and "Recycling carbon fiber for structural applications" under "Editor's Picks"). “Companies also need to continue scaling production capacity to tons per year,” Vilatela notes, “but we are at a point where this is more an engineering problem than one of fundamental science.”

State of the art

“Electrical conductivity is the most advanced functionality, because it is such a big issue for the composite airframe,” says Blanco. “We cannot yet eliminate the surface metal mesh for lightning strike protection, but we’re making good progress, have met specific electrical functions and identified specific additives that can work.” Ideas also are being developed for acoustic damping, but progress here is slower. Impact resistance is quite advanced, says Guinaldo, but self-healing, energy storage and morphing are longer-term, although the latter saw significant progress in the EU-funded SARISTU project.

Organizers of the 20th International Conference on Composite Materials (July 19-24, 2015, Copenhagen, Denmark), which featured more than 100 presentations on multifunctional composites, indicated that morphing and self-healing are probably 20 years away for commercial aircraft (see "Multifunctional composites: past, present and future" under "Editor's Picks"). Momentum is growing, however, and they believe energy-harvesting composites could see commercial use within a decade, most likely in UAVs and automotive structures. Although the promise is great, Guinaldo maintains, “The real multifunctional composites are those which add necessary functions but still meet all of the structural, manufacturing, cost, day-to-day service and end-of-life requirements of commercial aircraft parts.”

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

Recycling carbon fiber for structural applications

Research aims to characterize recycled carbon fiber (RCF) for use in aero interiors and also to recycle continuous carbon fiber.

Read MoreStructural health monitoring: NDT-integrated aerostructures

SHM moves from structural testing to an FAA-qualified inspection alternative, to reduce cost, streamline operations and mature toward lighter, more robust smart structures

Read More