Carbon Fibers

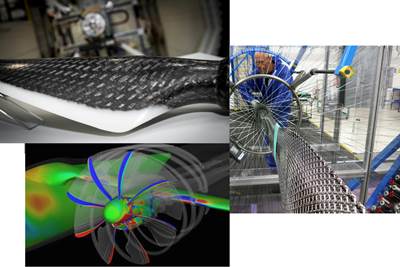

DigiProp positions Dowty Propellers and its customers for sustainable, next-generation platforms

AMRC aids R&D program including foam thermoforming, complex braiding, thermoplastics and digital twin/thread for higher performance, lower weight with first applications in process.

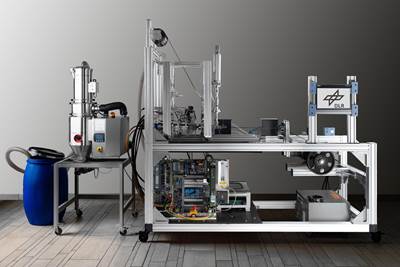

Read MoreReducing the cost of continuous fiber 3D printing materials

DLR has developed a novel approach to produce thermoplastic impregnated fibers for lower cost versus current slit-tape materials.

Read MoreNorth Carolina State University develops CFRP skin for stealth aircraft

The carbon fiber skin will enable the design of more reliable, durable and efficient stealth jets, offering better electromagnetic conduction and high temperature capabilities.

Read MoreMultifunctional composite structures across end markets

Innovators find new ways to add functions — from anti-icing to 5G signal transmission to structural batteries and beyond — into structural composites.

Read MoreAdditive manufacturing adds versatility to large marine structures

Dive Technologies and Moi Composites are among those extending composite 3D printing’s design flexibility past prototyping and into customizable end-use parts.

Read MoreQarbon Aerospace launches composite aircraft icing protection system

The thermoplastic composite Helios system will be distributed by AIR Group for use on the leading edges of turboprop aircraft wings and other components.

Read MoreEpic Aircraft receives FAA type certification for E1000 GX aircraft

The new E1000 GX is equipped with the Hartzell five-blade composite propeller, offering improved performance, safety, comfort and versatility.

Read MoreÉireComposites, Manna and NUIG to develop carbon fiber composite drone airframe

The aim to develop additive manufacturing and automation technologies for high-volume manufacturing of drones for 36% reduction in cost per drone.

Read MoreULA, RUAG Space extend and expand Atlas and Vulcan Centaur rocket programs cooperation

Contract adds additional order volume for RUAG Space’s supply and manufacture of carbon fiber composite structures until 2024.

Read MoreCevotec fiber patch placement improves storage efficiency of composite tanks

Cevotec’s solution is to apply carbon fiber patches to the dome areas of Type IV pressure vessels, which reportedly yields 15% in material, weight and cost savings.

Watch