ULA, RUAG Space extend and expand Atlas and Vulcan Centaur rocket programs cooperation

Contract adds additional order volume for RUAG Space’s supply and manufacture of carbon fiber composite structures until 2024.

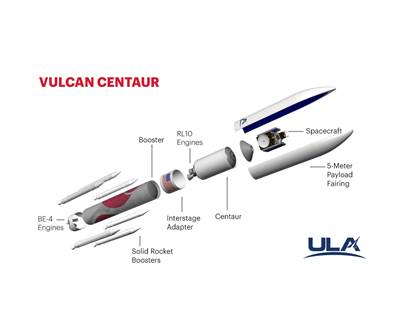

Photo Credit: ULA, RUAG Space

United Launch Alliance (ULA, Centennial, Colo., U.S.) and RUAG Space (Decatur, Ala., U.S. and Bern, Switzerland; renamed Beyond Gravity) have extended and expanded their cooperation. This announcement closely follows the signing of a contract for the fifth modification pertaining to the development and production contract (Mod5) for the Atlas and Vulcan Centaur rocket programs, which includes an additional order volume for RUAG Space composite products until 2024, amounting to 110 million Swiss francs (approximately $120 million).

“The partnership between ULA and RUAG has been a vital part of our successes over the many years,” says Daniel Caughran, ULA vice president of productions, operations and supply chain. “The recent contract modification reflects the ongoing trust and commitment to the partnership with RUAG Space as we proceed towards the first launch, and many future launches, of the Vulcan Centaur.”

Back in 2015, United Launch Alliance (ULA) announced a strategic partnership with RUAG Space to produce composite structures for the Atlas V rocket in the U.S. The move was part of the transition from the Delta and Atlas rocket programs to next-generation launch vehicles under the Vulcan family, of which components would be “flown first on Atlas V missions such as the solid rocket boosters, avionics, software, upper-stage engine and payload fairings, lowering the risk of the first flight,” according to CEO Tony Bruno. The Vulcan Centaur launch vehicle will be used for both satellite launches and manned missions.

Further, as part of the strategic partnership, RUAG Space set up shop in Decatur, Ala., U.S. in a 130,000-square-foot ULA building originally used for the Delta program and, following successful conversion, began operations in 2017 (see CW’s plant tour “Plant Tour: RUAG Space, Decatur, Alabama, U.S.”). Until 2017, the structures were produced at RUAG Space’s sites in Zurich and Emmen, Switzerland. The last structure manufactured in Emmen for the Atlas launch vehicle left Switzerland for the U.S. at the end of September 2020 on board an Antonov An-124 transport aircraft.

Now, partners report that production is taking place directly on site in Decatur, where RUAG Space will also manufacture the carbon fiber structures for the new Vulcan launch vehicle following successful development and qualification. The payload fairings, consisting of two half-shells that are mechanically joined together, are to be manufactured in a partially automated process and without the requirement of an autoclave, RUAG says. The fairings incorporate an aluminum honeycomb material sandwiched between an inner and outer cover layer of woven carbon fiber. A cork layer applied to the exterior reportedly provides thermal protection against frictional heat generated during launch. Carbon fiber will also be applied to the launch vehicle’s interstage adapters and heat shields.

In addition to the Vulcan launch vehicle, RUAG’s Decatur facility also currently supplies carbon fiber composite structures for ULA’s Atlas launch vehicles, including the payload fairing for the Atlas V-500 launch vehicle and the interstage adapter for the Atlas V-400. Since the beginning of the strategic partnership between ULA and RUAG Space, it it said that more than 120 successful rocket launches have been carried out by ULA using RUAG Space products.

Holger Wentscher, who heads the Launchers product group at RUAG Space, adds, “I would like to express my sincere thanks to ULA for the trust placed in us and for the cooperative partnership. With my colleagues at our Decatur facility, I look forward to continuing our shared success story.”

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreRead Next

United Launch Alliance progresses manufacture of Vulcan Centaur

Updates on the progress of the new launch vehicle, scheduled for launch in 2021, were announced at the 35th Space Symposium.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More