Carbon Fibers

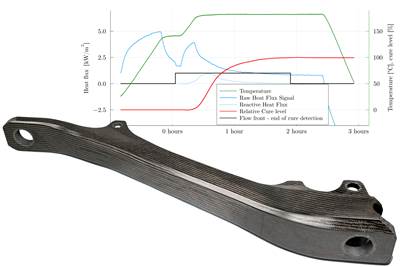

Speeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

Read MoreCobra International supports composite electric hydrofoil board evolution

Cobra continues to deliver materials, production process support, as well as manufacture Fliteboard’s carbon fiber Fliteboard Series 2 surfboards.

Read MoreQarbon Aerospace selected to assemble LIFT’s eVTOL aircraft

Leveraging its composite capabilities, Qarbon will perform the complete system integration and assembly for the carbon fiber HEXA eVTOL aircraft.

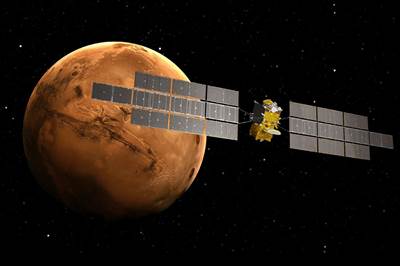

Read MoreESA and NASA validate Airbus Earth Return Orbiter design

Airbus and European suppliers prepare for production and assembly of the composites-intensive satellite to meet a 2025 delivery target date and 2026 launch.

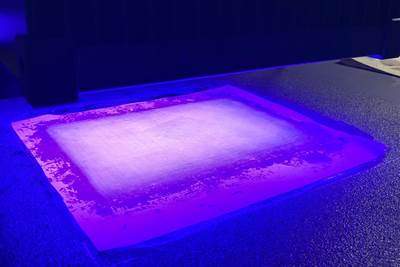

Read MoreEasy-to-use kits enable infield repair of composite structures

Portable kit enables patch repairs using UV-cure glass fiber/vinyl ester or room-temp stored carbon fiber/epoxy prepregs and battery-powered curing equipment.

Read MoreOptimization approach helps design lighter carbon fiber composites

Approach developed by Tokyo University of Science for manufacturing carbon fibers with optimized orientation and thickness achieves more than a 5% weight reduction in fiber-reinforced materials.

Read MoreTeijin Ltd. joins Spirit AeroSystem Aerospace Innovation Centre

Teijin expects to collaborate with Spirit and other AIC members to enhance innovative technology capabilities, including composites, in the aerospace industry.

Read MoreRobotic injection molding for functionalized composites

Anybrid enables compact, flexible hybrid injection molding/overmolding for smaller series and larger components.

WatchApply Carbon France invests in new manufacturing facility for recycled carbon fiber

The 15,600-square-meter facility will integrate the former ELG Carbon Fibre’s short carbon fiber business to address the growing market for sustainable technical fibers.

Read MoreSigmatex approved for National Manufacturing Competitiveness Levels funding

Industry-led program serves to increase Sigmatex’s CFRP capability and competitiveness relative to the changing needs of the automotive sector.

Read More