Composites 4.0

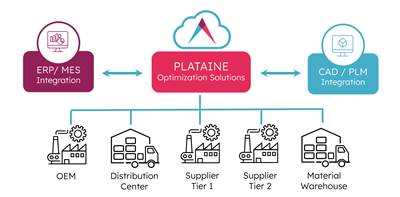

Plataine grows facility visibility, control with 3D Live Map launch

Composites manufacturers are able to proactively track, manage and streamline production status and resources use via a holistic, real-time view of the production environment.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreAitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.

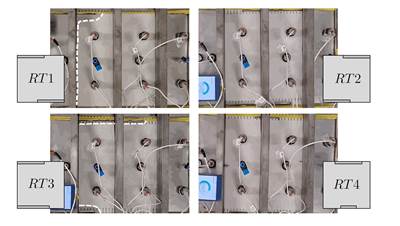

Read MoreCom&Sens presents workshop on fiber optic sensing for COPVs

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.

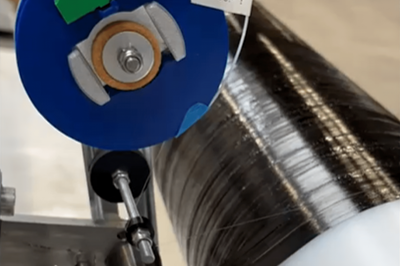

Read MoreIMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

Read MorePlataine expands NCC's AI, IoT optimization capabilities

Under this partnership, the NCC will leverage technologies such as time-sensitive material management and Plataine’s Digital Twin to further develop its composites R&D.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

WatchFIBRE4YARDS incorporates next-gen composites technologies to redefine shipbuilding

At the project’s completion, consortium members have unveiled final results and a 1:1 scale demonstrator, highlighting the opportunities for more collaborative, digitized, automated, efficient and environmentally friendly shipyards.

WatchPlataine releases enhanced version of Digital Thread Portal

The cloud solution delivers digital thread connectivity across multiple sites and organizations, enabling manufacturers to automate material receiving and maintain a complete digital genealogy of their products.

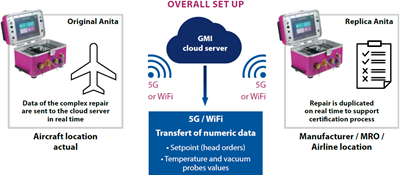

Read MoreGMI Aero enhances digital/physical twin network application for Anita hot bonder

EVOLVED-5G project seeks to test, validate and certify, in a vendor-agnostic experimentation 5G platform, Industry 4.0 network applications.

Read More