Composites 4.0

CAMX 2022 exhibit preview: Schuler North America

Schuler’s smart control systems are said to achieve high material savings by reducing waste throughout the material cutting, distribution and forming processes.

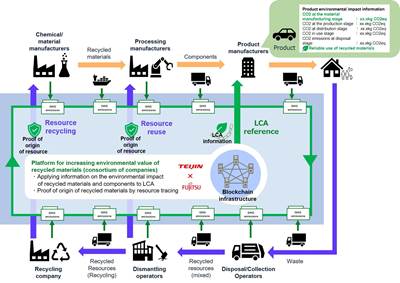

Read MoreTeijin, Fujitsu to develop blockchain-based commercial platform for recycled materials manufacturing

The platform aims to enhance the environmental value of recycled FRP materials for manufacturers through life cycle assessment calculations and more reliable information management.

Read MoreVoith Composites partnership with Gazechim Group delivers Carbon4Tool tooling system to Europe

With Gazechim Group as the European distributor, Voith hopes to empower faster, easier and more effective CFRP tool manufacturing via its next-generation technology.

Read MoreGerman UniFix project develops mobile holding fixture to enhance production efficiency of large CFRP structures

Fraunhofer IFAM and Airbus Operations in Stade demonstrate reduced manual handling and non-productive time in flow-oriented manufacturing of vertical tail plane.

WatchAtlas Copco’s GHS VSD+ vacuum pump range offer Industry 4.0 functionalities

Variable speed-driven, oil-injected screw vacuum pumps are well suited for the infusion process, complete with 15% smaller footprint, integrated HEX@TM controller and optimized performance.

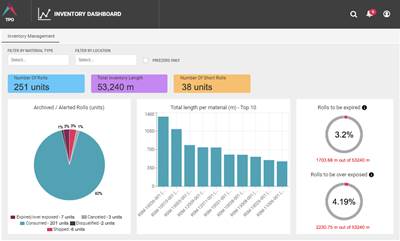

Read MorePlataine extends digital thread technology to overcome supply chain challenges in composites

Cloud and AI technologies provide composites manufacturers a traceable, secure digital thread to stretch from raw material to end product, improving supply chain visibility and quality control.

Read MoreComposites supply chain and production disruptions – how can AI and digitalization help?

Digitizing and creating the factory of the future is a journey, but it has the potential to help composites manufacturers address real-life disruptions and enable fast replanning of production operations for increased flexibility and enterprise-level performance.

Read MoreLaboratory for Intelligent Lightweight Production at CTC Stade advances digital solutions for industrial composites

Four-year, 12-million-euro LaiLa project with Helmut Schmidt University combines R&D with industry collaboration to solve real production pain points, validate solutions in digital lab/model factory at CTC and transfer knowledge to supply chain including customized training.

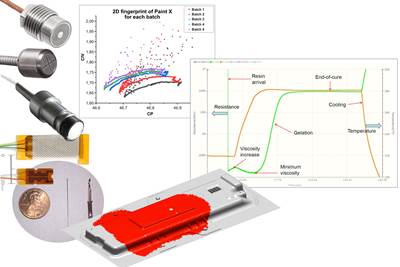

Read MoreSensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

WatchFACC seeks 200 new hires in IT, digitalization, innovation and automation

Upswing in aviation, including 2021 new contracts worth €1 billion, impels FACC investment of €150 million to support short-cycle processing of lightweight composites, recycling and expanded production via automation and next-gen manufacturing technologies.

Read More