Design & Tooling

Thermoplastic components successfully flight tested on Bell V-280 Valor

The components were manufactured for Bell by GKN Aerospace for the V-280 Valor tiltrotor.

Read MoreF-35 Lightning program adopts closed molding technology

Reduced manufacturing time and high part-to-part dimensional repeatability are some benefits of Matrix Composites’ HiRPM molding technology.

Read MoreGermany's aerodyn launches rotor blade for 11-15 MW turbines

The rotor blade boasts CFRP-GFRP spar caps, a 128-meter rotor diameter, an adjustable design and more.

Read MoreBroetje-Automation presents automated sealer for aircraft components.

The automated, modular system enables clean, safe and speedy production for all aircraft component sealing.

Read MoreComposites speed concrete facade fabrication

The 45-story One South First building, on the 11-acre Domino Park campus in Brooklyn, N.Y., features a geometrically complex concrete facade made, in part, with composite molds fabricated using large-format additive manufacturing.

Read MoreToray introduces high tensile modulus carbon fiber and thermoplastic pellet

With a carbon fiber diameter of 7 microns, the Torayca T series balances cost performance with a high tensile modulus.

Read MoreCoriolis Composites and Edixia develop inline inspection for AFP

Video and discussion of how the sensor and software operate to boost composites productivity

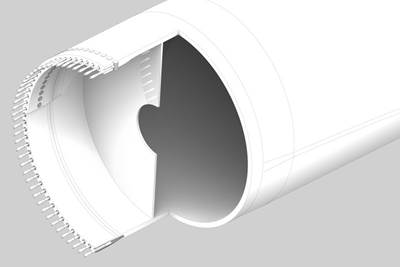

WatchMagnum Venus products launches fusion filament winder

Ideal for winding pressure vessels, the Fusion filament winder is a compact, adaptable design.

Read MoreAnomalies force Virgin Orbit to terminate LauncherOne test

Despite the termination, the test flight provided data necessary to make adjustments for future launches.

Read MoreVertical Aerospace used Plyable to go from CAD to first flight in less than 90 days

Composite tooling specialist’s online portal, distributed manufacturing network and automated tool design helped optimize CFRP molding tools and timeline.

Read More