Germany's aerodyn launches rotor blade for 11-15 MW turbines

The rotor blade boasts CFRP-GFRP spar caps, a 128-meter rotor diameter, an adjustable design and more.

Source | aerodyn

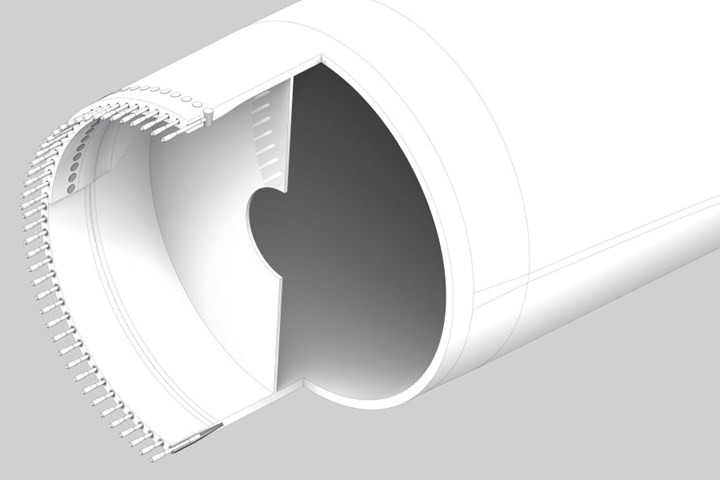

Wind turbine specialist aerodyn Energiesysteme GmbH (Rendsberg, Germany) reports that it has developed a 111-meter TC1B rotor blade for 11-15 MW wind turbines. To reduce the cost of using carbon fiber, aerodyn says the blade design features hybrid CFRP-GFRP spar caps and can be adjusted according to wind turbine specifications and site conditions.

At a rated power of 14,000 kilowatts, aerodyn’s rotor blade design features a 128-meter rotor diameter with a nominal speed of 7.54 rpm and nominal tip speed of 90 m/s. A 1B design class type, the 14-MW blade maintains a 7.018-meter maximum chord and has 4 meters of prebending at the blade tip. Additionally, the BCD blade root length reaches 5,050 millimeters.

The company is currently working on 10-MW offshore wind turbines, as well as a future generation of 15-MW systems. For more information, read aerodyne’s technical data sheet.

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Daher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.