Design & Tooling

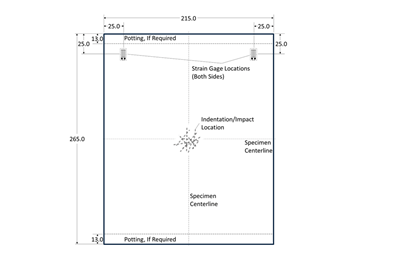

Damage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

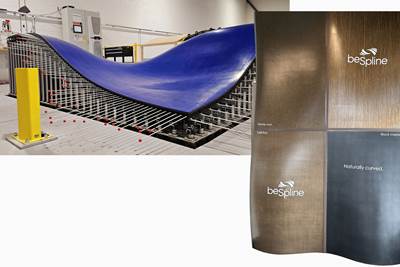

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreBelotti retrofits Vega CNC center in BEAD hybrid machine for D-Composites

Combined LSAM and five-axis CNC milling capabilities will optimize D-Composites’ production services, flexibility and cut time and cost for composite tooling manufacture.

Read MoreElement, Magma Global renew partnership to extend m-pipe capabilities

Evaluation of CFRTP m-pipe through Element’s U.K. facility aims to qualify the system for new operating environments.

Read MorePRF Composite Materials granted U.K. patent for Q.tool

Innovative prepreg tooling is highly drapable, capable of forming complex carbon fiber tooling shapes, in addition to reducing through thickness porosity and only requiring one debulk during layup.

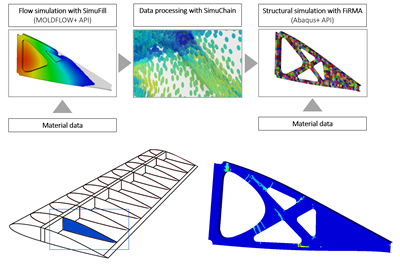

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

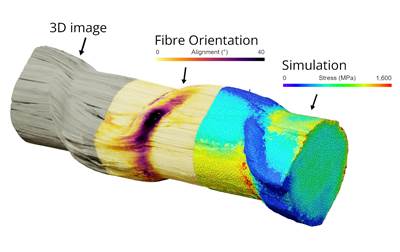

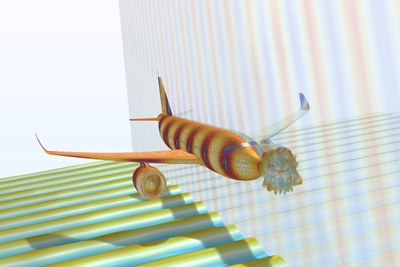

WatchNew Frontier Technologies launches digital twinning, high-fidelity simulation capability

3D imaging and analysis capability illustrates detailed, quality characterization and performance simulation of composites and other advanced materials that properly captures the as-manufactured component.

Read MoreComsol releases version 6.2 of Comsol Multiphysics software

Latest version of comprehensive simulation software speeds up computations and introduces surrogate model functionality.

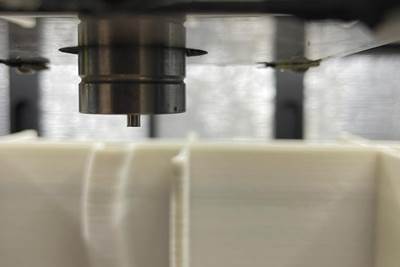

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

WatchFilton Systems Engineering is acquired by Element Materials Technology

Distinguished by its aerospace engineering and testing services, including work with composite hydrogen tanks, FSE increases Element’s digital engineering and aerospace capabilities.

Read More