Design & Tooling

Carbon fiber tooling addresses aerocomposites pain points

CAMX 2023: The result of extensive R&D, BlackBoard by Harcourt Industrial enhances efficiency, reduce costs and improve overall manufacturing performance compared to Invar tools.

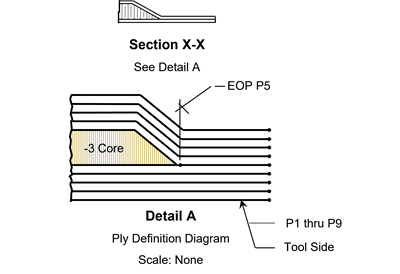

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

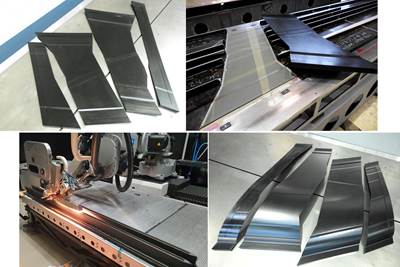

Read MoreMachine, equipment investment strengthens Ruckus Composites’ research, innovation

CNC services expansion, universal testing machines and advanced inspection enable Ruckus to delve deeper into the study and evaluation of carbon fiber damage, as well as nondestructive and destructive testing.

Read MoreVericut 9.4 enhances manufacturing workflow connectivity

CGTech’s latest release for the standalone software includes streamlined optimization, improved reviewer files, tool data enhancements and a new ToolsUnited interface.

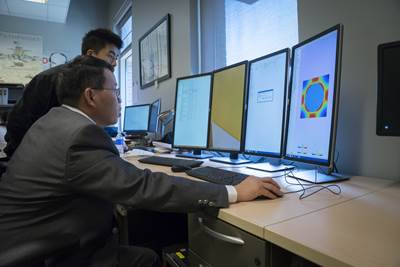

Read MoreAnalySwift receives $800,000 contract to improve composites simulation

The Phase II STTR contract from NASA, adding on to the company’s two Phase I programs in 2022, enables AnalySwift to develop and release DATEC, a design tool for engineers to design and analyze tailorable composite structures.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

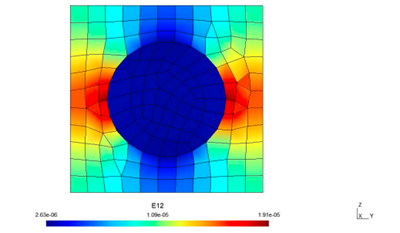

Read MoreBrazilian university leverages Swiftcomp simulation software for composites

The Federal University of Paraiba is studying composites with spherical inclusions of silicon carbide and aluminum matrix, aided by AnalySwift’s composites simulation code.

Read MorePlyable recognized as Boeing Aerospace Xelerated portfolio member

Composite tooling automation platform is a cohort 1 graduate from Boeing-backed accelerator program for digital startups that can move the aerospace industry forward.

WatchTake the Plataine composites industry survey

This short survey is designed to help assess the composites industry’s willingness and ability to adopt new technologies. Respondents receive results. Survey closes soon — complete yours today.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read More

.jpg;maxWidth=300;quality=90)