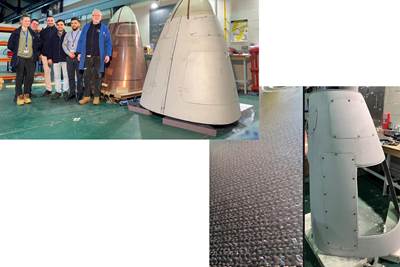

Design & Tooling

Composites UK launches best practice guide for composites tooling

“Mould Tooling for Fibre-Reinforced Polymer Composites” is latest in Composites UK’s series of good practice guides, available online for free.

Read MoreBase Materials announces new distributor to support growth in European composites market

B. Beyer GmbH will distribute Base Materials’ range of epoxy and polyurethane tooling board materials and ancillary products.

Read MoreCryogenic qualification services provide quality material evaluations

CAMX 2023: Precision Measurements and Instruments Corp. is an ISO/IEC 17025-accredited testing laboratory that characterizes materials from cryogenic to elevated temperatures.

Read MoreD-JOINTS project helps engineers protect composite aircraft structures from lightning strikes

Design of innovative composite hybrid joints with electromagnetic compatibility project tested and validated two types of joint technologies plus software tool for faster design.

Read MoreZenvo Automotive announces partnership with Managing Composites

New benchmarks for performance, design and safety can be anticipated with the Aurora platform, backed by Managing Composites’ support of the hypercar and supercar industry, and its extensive knowledge in composite materials and simulation.

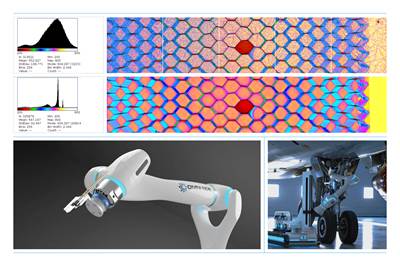

Read MoreAutomated NDE equipment brings new inspection capabilities

CAMX 2023: Omni-NDE combines cobots/small robots with novel sensors to provide automated, contactless inspection of composites.

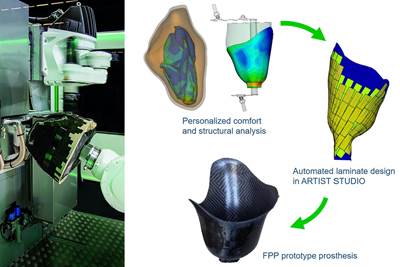

Read MoreCevotec’s fiber patch placement is part of digital process chain for automated composite prosthetics

Multiple partners work to develop automated data collection, composite laminate generation for customized medical applications using FPP technology in German-funded Patch2Patient project.

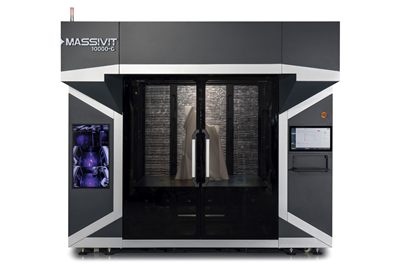

Read MoreLarge-scale additive system prints industrial molds for composites

CAMX 2023: The Massivit 10000-G, with gel dispensed printing offers an ultra-fast, sustainable and cost-effective way to digitize isotropic mold production for high-quality and more reliable composite parts.

Read MoreSolico engineers sustainable Duplicor composite façade for The Pulse

Using long-term client Holland Composites’ 100% bio-based composite solution, Solico optimized the engineering of the new building’s approximately 1,100 composite elements.

Read MoreOptimized approach to predict delamination failure in CFRTP structures

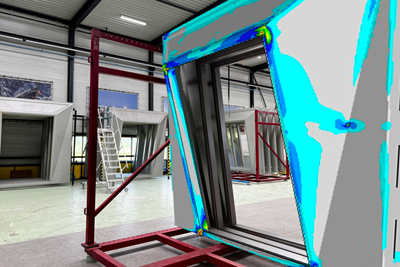

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read More

.jpg;maxWidth=300;quality=90)