Zenvo Automotive announces partnership with Managing Composites

New benchmarks for performance, design and safety can be anticipated with the Aurora platform, backed by Managing Composites’ support of the hypercar and supercar industry, and its extensive knowledge in composite materials and simulation.

Photo Credit: Zenvo Automotive, Managing Composites

Zenvo Automotive (Præstø, Denmark) announces its technical partnership with engineering and simulation specialists, Managing Composites (Madrid, Spain), for the build of the all-new Aurora hypercar. This second major technical partner announcement cements Zenvo’s intentions of firmly establishing its presence in the hypercar sector.

Together with Managing Composites, Zenvo is targeting a composite platform with a rigidity of 63,000 newton-meters/degree between suspension hardpoints, while weighing under 120 kilograms, (or an equivalent monocoque exceeding 75,000 newton-meters/degree in less than 64 kilograms). The Aurora is said to solidify Zenvo Automotive’s commitment to push the limits of what is possible and to meet the latest, extreme requirements for hypecars by working with Managing Composites as an authority in composites engineering and development.

Zenvo cites Managing Composites’ reputation in providing support for many of the supercar and hypercar OEMs around the world, noting that the company’s founders have been working within the super and hypercar industry for more than 15 years.

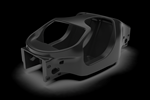

Due to the secrecy required around this work, Managing Composites is generally not able to talk about these projects. However, Zenvo does report that Managing Composites will spearhead the development of a carbon fiber platform for the Aurora. At the heart of this platform is the monocoque, a critical component that ensures structural integrity and rigidity in the hypercar construction. Applying its understanding of composite materials, design peculiarities and advanced simulation techniques, Managing Composites is expected to deliver a distinctive carbon fiber structure that not only delivers high performance but also mesmerizing aesthetics.

“Jens and I have previously worked together on other projects,” says Lluc Martí, CEO at Managing Composites, “and then he reached out to me. I could feel his passion and excitement around the Aurora. From the very beginning, it was evident that this was a project we had to be a part of. And I must say, it has exceeded all of our expectations. It is truly a game changer in every sense.”

The partnership between Zenvo Automotive and Managing Composites goes far beyond just the monocoque. With extensive expertise in crash and structural simulation, Managing Composites will help to ensure that the Aurora project surpasses the highest safety standards. By incorporating composite crash structures inspired by Formula 1 technology, Aurora will provide enhanced energy absorption and occupant protection during impact scenarios. Safety will be as paramount as performance.

In addition to their contributions to the core platform, Managing Composites have a pivotal role in the design and development of body panels and trim. Leveraging vast experience and a “design for manufacturing” mindset, the Madrid-based team will create lightweight and aerodynamically efficient components which will not only enhance the overall performance of Aurora but also deliver a sense of automotive artistry and craftsmanship.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.