Design & Tooling

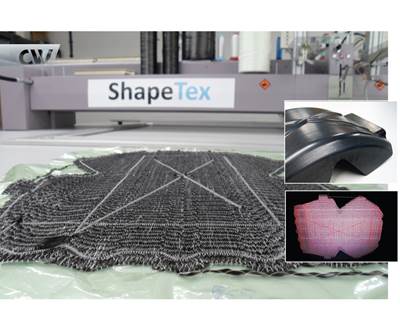

CAMX 2017 preview: Convergent Manufacturing Technologies

Convergent Manufacturing Technologies Inc. (Vancouver, BC, Canada) and its US-based partner Convergent Manufacturing Technologies US Inc. (Seattle, WA, US) are demonstrating their turnkey digital manufacturing solutions.

Read MorePreforming goes industrial: Part 2

Automated preforming isn’t only for 2D and 2.5D parts. Innovators are taking successful aim at building 3D preforms at production speeds.

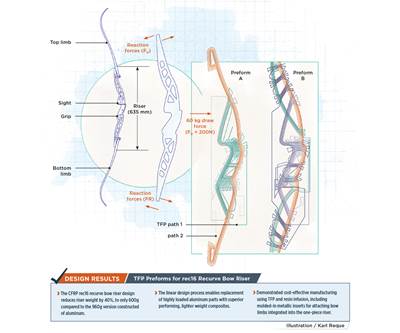

Read MoreVariable-axial composites open path to lighter composite structures

CFRP recurve bow riser demonstrates design and manufacturing approach with potential to cut weight vs. aluminum by 50-75% while increasing strength and stiffness.

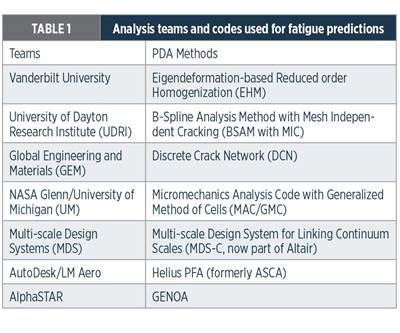

Read MoreHow ready are progressive damage analysis tools?

In the past 15 years, progressive damage analysis (PDA) for composites, implemented in finite element analysis software, has been under development.

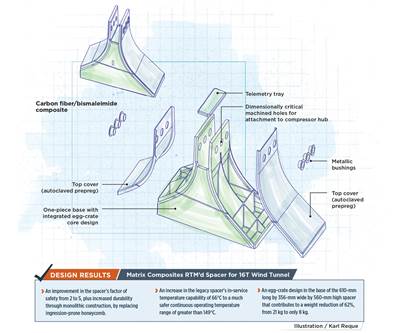

Read MoreRTM-based redesign advances safety for one-of-a-kind wind tunnel

Glass fiber and honeycomb spacers between compressor blades get upgraded to a higher factor of safety with less weight using solid carbon fiber and RTM.

Read MoreShape Machining shapes Elemental sports car

Designed and manufactured by a team of ex-McLaren designers, the recently launched RP1 features advanced aerodynamics and novel composite solutions, including an all-carbon composite passenger tub built to Formula 1 strength and stiffness standards.

Read MoreComposites in transit: Rolling robotic “stuff carrier” the new must-have

PPF’s Gita can move at a human walking pace or can accelerate up to 35 kph, fast enough to keep pace with a runner.

Read MoreAdditive manufacturing and composites: An update

Additive manufacturing has only begun to tap the potential available in the composite industry.

Read MorePreforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

Watch3D printed tools are in production at Dassault Falcon Jet

The trend of employing polymeric additive manufacturing (AM) or 3D printing for composite tooling is growing.

Read More

.jpg;maxWidth=300;quality=90)