Design & Tooling

Stratasys, Siemens partner to advance AM into volume production

The partnership aims to strengthen and expand the benefits of 3D printing in the manufacturing value chain.

Read MoreInnovation: Moving faster than ever

The rate of composites innovation is higher than I’ve ever seen, and the implications are significant.

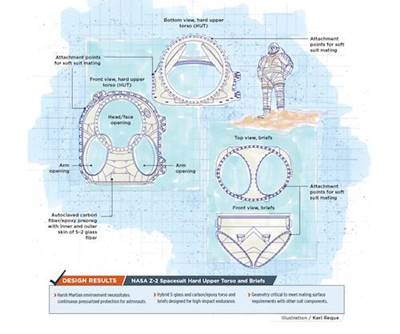

Read MoreOn Mars, not just any suit will do

NASA seeks impact resistance in next-generation space suit.

Read MoreComposite repair: Lessons learned, challenges and opportunities, Part I

As aerospace companies look to increase the scope and quality of repairs, through standardized training and increased automation, their lessons learned (outlined here in Part 1 of a two-part examination) can smooth the repair path for other industries.

Read MoreComposites enable portability in driving simulator

FRP design enables portable, light-tight, enclosure with an image-projection-grade inner surface.

Read MoreHistory, myths and urban legends of pultrusion

CW guest columnist and composites industry pultrusion consultant David E. Green tells us that many interesting stories have been told about the early days of pultrusion, and some of them are true.

Read MoreStratasys debuts Robotic Composite and Infinite-Build 3D printers

The company says this new 3D printing technology produces larger, lighter production parts for aerospace and automotive.

WatchBionic design: The future of lightweight structures

Biomimicry evolves into a systematic design process for optimizing efficient, lightweight structures.

WatchThe steadily growing list of IACMI resources

IACMI, the public-private composites consortium, is a little more than a year old and already has developed a strong collection of partnerships, facilities, equipment, software and material designed to help accelerate new technology development for the composites industry.

Read MoreMETYX Composites expands Turkey site

The expanded site is almost twice the size of the current factory, providing METYX with the space to double weaving capacity for glass and carbon fiber multiaxial fabrics.

Read More