Brazilian university leverages Swiftcomp simulation software for composites

The Federal University of Paraiba is studying composites with spherical inclusions of silicon carbide and aluminum matrix, aided by AnalySwift’s composites simulation code.

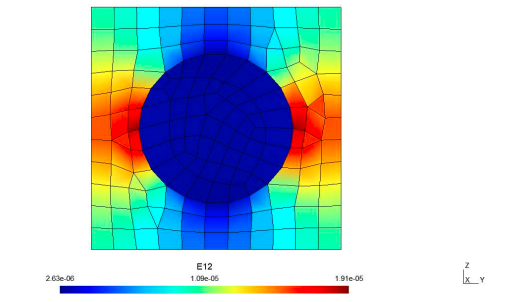

A simulation performed with the help of SwiftComp and third-party software provider, Ansys, demonstrates a deformation field for carbon fiber-reinforced epoxy composites. Photo Credit: Federal University of Paraiba, AnalySwift

The Federal University of Paraiba (João Pessoa, Brazil) is participating in AnalySwift LLC’s (West Lafayette, Ind., U.S.) Academic Partner Program (APP), and it is using its SwiftComp simulation software for researching composite materials. The work is part of the research being conducted in the Department of Mechanical Engineering.

The APP offers participating universities no-cost licenses of engineering software programs VABS and SwiftComp so students, researchers and faculty can leverage the tools in their academic research.

The SwiftComp program general-purpose multiscale modeling code that enables users to perform efficient and accurate modeling of composites and other advanced materials — such as metamaterials, architected materials, porous materials, tailorable composites, etc. It can be used either independently as a tool for virtual testing of composites or as a plugin to power conventional FEA codes with high-fidelity multiscale modeling.

“We studied the composite with spherical inclusion of silicon carbide and aluminum matrix,” says Raul Bernardo de Pontes Pires, a graduate student at Federal University of Paraiba working under the direction of Prof. Marcelo Cavalcanti Rodrigues. “Through SwiftComp, we were able to better understand the behavior of composite materials quickly and effectively. We

compared the methods of homogenization of the mean fields with the values obtained by SwiftComp and had excellent precision.”

“After validating the midfield homogenization models, the team developed a matlab software for homogenization of composite materials using the dilute suspension, Mori-Tanaka, a self-consistent and differential scheme for spherical inclusion, aligned and misaligned fiber composites,” continues Pires. He notes that several charts demonstrate the comparison of the homogenization through the homogenization model of the mean fields with the values obtained by SwiftComp, which show nice agreement. “I’d like to thank the AnalySwift team, because through this software I managed to greatly develop my knowledge about composite materials,” he adds. “I also commend the fact that they are supporting the development of science and technology through their Academic Partner Program.”

“SwiftComp saves hours in computing time and resources with accuracy comparable to modeling all the microstructural details using 3D FEA,” says Dr. Wenbin Yu, CTO of AnalySwift. “It can also predict accurate local stresses and strains in the microstructure for the purpose of predicting strengths, as well as thermal expansion of composites.”

AnalySwift’s SwiftComp program has aided several others in their work to virtually test composite materials, many of which can be viewed here.

Related Content

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

-

ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.