Feature

Reprocessable thermosets and thermoplastic epoxies: An expanding landscape

New chemistries give thermosets new thermoplastic-like versatility.

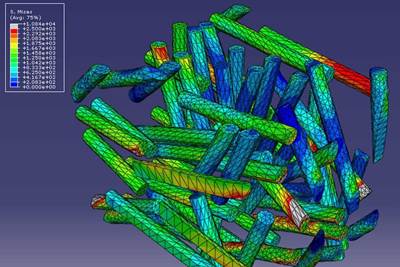

Read MoreNext-generation composites qualification

Fully digital qualification hasn’t yet arrived, but simulation and analysis software continue to evolve and work together with physical testing practices.

Read MoreBridging the gap between CFRP and CMC

Novel composites offer performance up to 1000°C with faster processing.

Read MoreAutomated aerocomposites production: Liquid molding or welded thermoplastic?

Two materials and process approaches are demonstrated for CFRP bulkhead production.

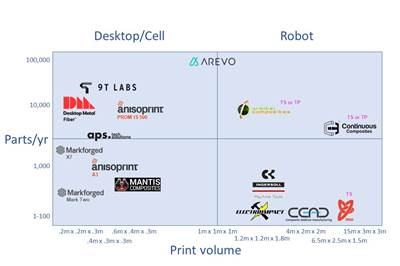

Read More3D printing with continuous fiber: A landscape

Growth continues in suppliers, part size, production volume and markets.

Read MoreComposite aerostructures in the emerging urban air mobility market

In the not too distant future, point-to-point, limited-distance, piloted and autonomous air travel for people and cargo will be the norm. Composites will make it possible.

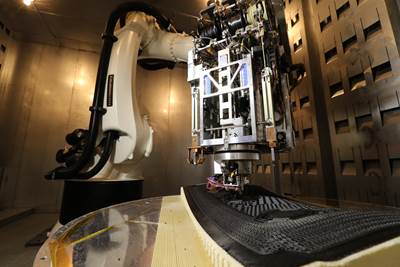

Read MoreCombining AFP with 3D printing for flexible parts production

Electroimpact creates a multifunctional manufacturing cell for complex, aero-quality continuous fiber composite parts.

WatchUpdate: Lower wing skin, Wing of Tomorrow

Airbus is evaluating several advanced composites technologies as part of its Wing of Tomorrow program. Among these is liquid resin infusion of the lower wing skin, being developed by Spirit AeroSystems.

WatchComposites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

Read MoreComposites in the race to space

Advanced materials use in current and upcoming NASA missions.

Read More