Feature

Cycling forward with bike frame materials and processes

Fine-tuning of conventional materials and processes characterizes today’s CFRP bicycle frame manufacturing, whether in the large factories of Asia or at reshored facilities in North America and Europe. Thermoplastic resins and automated processes are on the horizon, though likely years away from high-volume production levels.

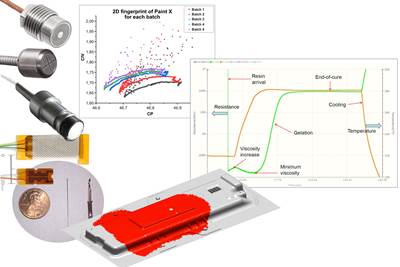

Read MoreSensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

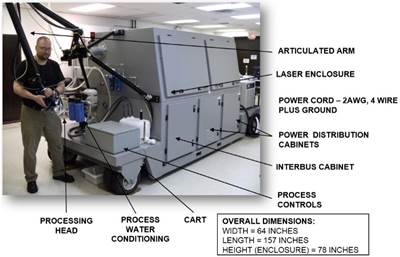

WatchLaser bondline inspection becomes reality

One of the Holy Grails of composites manufacturing has been reliable verification of adhesive bondline strength integrity. A technology that does just that has arrived.

Read More2021 CW Top Shops highlights strengths of top composites facilities

CW learned from some of this year’s designated Top Shops about what makes facilities stand out, from diverse capabilities to Industry 4.0 and sustainability.

WatchHydrogen is poised to fuel composites growth, Part 2

Potential for Type IV composite tanks in H2 refueling stations and distribution, plus targeted cost reductions and emerging technologies for tank recertification and monitoring.

Read MoreRefrigerated railcar floor expands composites horizons

TrinityRail, in an effort to update a 20-year-old design, seizes the opportunity to apply composites in a structural application in its refrigerated railcar. It’s a first for the rail and composites industry.

Read MoreHydrogen is poised to fuel composites growth, Part 1

Applications abound for composite tanks to store compressed H2 gas, but challenges exist in cost, size, efficiency and limited carbon fiber capacity.

Read MoreOut-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

Read MoreComposites AM research targets wind energy

The U.S. DOE, universities and industry leaders ramp up new efforts and funding to develop 3D-printed composite wind blade molds and end-use blade components.

Read MoreChallenges, opportunities when designing for fiber-reinforced AM

Bridging the gap between as-designed and as-made, and where do you put the fiber?

Read More