Engine exhaust structures made with PyroXide (left) and PyroSic (right) materials. PyroXide uses 3M Nextel aluminum oxide fibers, resulting in a composite very similar to Ox-Ox CMCs in a conformable prepreg that does not require darting and pleating to make complex shapes. Photo Credit: Pyromeral

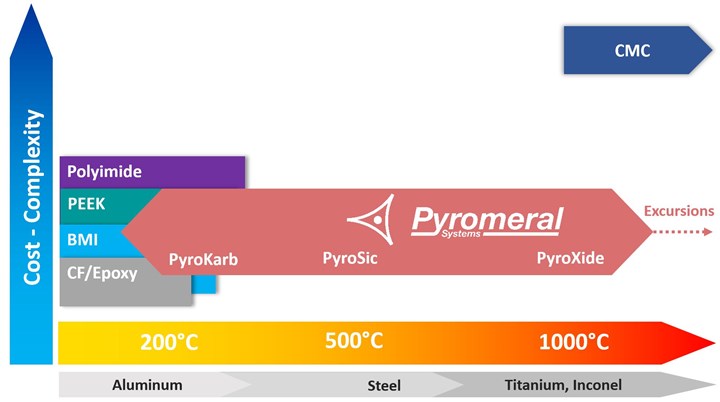

Materials that enable high-performance structures at service temperatures above 500°F/230°C are limited. The options are basically metals such as titanium and alloys like Inconel, polyimides (PI) or ceramic matrix composites (CMC). All of these are significantly more costly than conventional carbon fiber-reinforced polymer (CFRP) composites, but CMC have been gaining interest due to their low density — roughly one-third that of Inconel and one-half that of titanium. The downside of CMC has been the long processing times required to make parts — just short of 30 days, according to an April 2019 article in the American Ceramic Society Bulletin.

However, Pyromeral (Barbery, France) has developed a family of products that bridge this gap, offering performance up to 1,500°C with processing that is more akin to CFRP, producing parts in roughly one week. “We have developed novel chemistry that enables advanced glass-ceramic matrices reinforced with continuous fibers without the lengthy melt infiltration step,” explains Pyromeral’s sales and marketing director Guillaume Jandin. The company offers PyroKarb, PyroSic and PyroXide materials reinforced with high modulus carbon, silicon carbide and aluminum oxide fibers, respectively, typically in the form of two-by-two twill fabrics, resulting in composites with a fiber volume fraction (FVF) of 50%.

Fiber-reinforced glass-ceramic matrix parts

Pyromeral has developed a family of water-based, glass-ceramic matrix materials reinforced with carbon, silicon carbide and aluminum oxide fibers for its PyroKarb, PyroSic and PyroXide products respectively. Photo Credit: Pyromeral

Thermal performance factors

Jandin explains that while all three Pyromeral materials can perform above 1000°C for less than 1 hour, PyroKarb offers long-term (less than 1,000 hours) service at 200°C, and up to 100 hours at 500°C. PyroSic offers long-term service at 500°C and up to 100 hours at 800°C. PyroXide offers short service up to 1,500°C, very close to the performance of Ox-Ox CMC, but at a lower cost.

“Thermal performance in actual parts depends on many factors,” says Jandin. “These include the type of heat (radiative, convective), whether there is air flow to help cool down some areas of the part and also what structural properties are required — for example, a non-structural heat shield or semi-structural part. Whether the materials work at continuous high temperature or in short-duration flashes is also critical,” he adds. “PyroSic and PyroKarb work well with the latter, such as repeated cycles of 1000°C for one-tenth of a second, cool down and then repeat. Their low coefficient of thermal expansion (CTE) of roughly 3.10-6 µm/m/K is a benefit compared to metals, which tend toward a CTE greater than 10.10-6 µm/m/K. These types of metals incur stress to accommodate rapid, high-temperature thermal cycling and degrade due to fatigue, while our materials do not.”

CFRP-like processing, high-temp applications

Conformable prepreg, high-temp parts

Pyromeral materials result in a fireproof glass-ceramic matrix. At a one-millimeter wall thickness, PyroSic (shown here) can pass aerospace flame, smoke and toxicity tests and retain more than 90% of mechanical properties. Photo Credit: Pyromeral

“We invented our matrix materials to be liquid at room temperature and use impregnation machines to create prepreg,” notes Jandin. The prepregs are laid onto CF/epoxy tools. “We don’t work with metal tools because our matrix is alkaline and might react,” he adds. “The next step is autoclave densification at 100°C and 6 bar for roughly 12 hours.” Parts are demolded and then proceed, free-standing, through a two-stage thermal process at 500-1,000°C which, completes ceramization of the matrix, resulting in structural components.

Pyromeral found early success in Formula 1 race cars. “Our materials are used in heat shields around engines and also around brakes, which reach temps of 500-700°C,” says Jandin. “During the 2012-13 F1 season, every car except Sauber used our materials for parts to direct engine exhaust gas (800°C). These structures also resisted vibration from both the exhaust and chassis. We now have components on every car racing in F1.”

“Also, we can integrate high-performance insulation into our materials to withstand drops of 700°C with a 6-millimeter thickness,” he continues. “For example, we make components that enable an F1 race car gearbox made of CF/epoxy — which must stay below 180°C — to sit within 20 millimeters of the turbocharger at 900-950°C.” Other applications include a PyroXide heat shield qualified for the Ariane 5 launch vehicle and parts for the Ariane 6, as well as PyroSic exhaust exits for large unmanned aerial vehicles (UAVs).

Pyromeral has partnered with Composite Resources (Rock Hill, S.C., U.S.) to expand its market in the U.S. (see “The building of a composites manufacturing niche”). The companies are similar in size and share a long history in racing. “Our experience in parts design and manufacturing is complimentary to Pyromeral’s focus on chemistry and materials performance,” says Composite Resources business development director Melvil Clauson.

PyroSic materials allow processing more akin to CFRP compared to CMCs and are generating interest for a wide range of aerospace, defense, automotive and industrial applications.Photo Credit: Pyromeral

The two companies are working to meet customer demands for even higher temperature resistance and to characterize PyroXide’s high radio frequency (RF) transparency for use in radomes and antennas. “We’re seeing interest regarding supersonic aircraft and very broad-based defense applications beyond the Air Force, as well as in commercial jet engines,” notes Clauson.

“Pyromeral products are also future-looking,” says Clauson, “because they contain no petroleum-based substances — only water as a solvent. The other constituents are minerals, enabling us to process end-of-life parts into powder that can be reused in other applications.”

Related Content

MATECH C/ZrOC composite is deployed in hypersonic aeroshells

Ultra high-temperature insulating CMC targets hypersonics, space heat shields and other demanding applications, tested up to 2760°C under extreme stagnation pressures.

Read MoreBombardier begins manufacture of Global 8000 business jet

Ultra-long range business jet featuring CMC-intensive engine and a range of 8,000 nautical miles is set to enter service in second half of 2025 as it remains on track for flight testing.

Read MoreDeveloping milling for CMC because grinding takes too long

Economical processes that can cut machining time by 70% are being tested on aeroengine turbine blade demonstrators by Hufschmied and DLR in the SCANCUT project.

Read MoreMATECH’s FAST technology achieves ultra-high density C/C composites

Targeting demanding hypersonic missile applications and ballistic reentry, the patent-pending process increases C/C composite ablation and oxidation resistance by 20 times.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More