Share

Read Next

CW photo | Scott Francis

July 20, 2019 marked the 50-year anniversary of the first Apollo moon landing. Though, at the time the Apollo capsule was built, the composites industry was still in its infancy and the materials were not yet in widespread use, the Apollo capsule used early composite technology in the form of an ablative heat shield made from Avcoat, an epoxy novolac resin with silica fibers in a fiberglass-phenolic honeycomb matrix. A fiberglass honeycomb was bonded to the primary structure and the paste-like material was injected into each cell individually. Since Apollo, advanced composites have evolved by leaps and bounds, and have played a significant role in space programs with use in launch vehicles, the space shuttle, satellites, space telescopes and the International Space Station.

Today, the human race finds itself poised for some exciting new steps into space exploration. The current administration has called for a return to the moon by U.S. astronauts by 2024 and has announced a 2021 budget of more than $25 billion for the National Aeronautics and Space Administration’s (NASA, Washington, D.C., U.S.) human space exploration program. NASA administrator Jim Bridenstine says the budget is “one of the strongest budgets in NASA history.”

Old school. Apollo’s heat shield was made of epoxy phenolic novolac resin in a fiberglass honeycomb. CW photos | Scott Francis

In addition to another moon shot, NASA has current and forthcoming missions to study our solar system from the sun to the icy moons of the outermost planets and beyond. Missions to explore the sun are currently underway: at the time of this writing, the Parker Solar Probe is currently monitoring the sun’s atmosphere and a Solar Orbiter has successfully launched. Efforts are also underway to further the exploration of exoplanets and distant galaxies through the Transiting Exoplanet Survey Satellite (TESS) mission and the James Webb Space Telescope, the latter of which has made strides toward launch-readiness over the past year.

New spacecraft and programs have also resulted in recent years from increased collaboration between national and international space agencies as well as commercial companies. For example, SpaceX (Hawthorne, Calif., U.S.), with its Crew Dragon spacecraft, and Boeing Space and Launch (Arlington, Va., U.S.), with its Starliner spacecraft, are racing toward the first crewed U.S. spaceflight since the discontinuation of the space shuttle program in July 2011. The two companies have been performing test flights with NASA in hopes of a crewed mission in 2021.

From the increased support of NASA’s space program to the explosive growth of commercial space, the human race seems truly poised for the next great space age. Composites and advanced materials play an increasingly larger role in the manufacture of the launchers, spacecraft and instruments that make all of this exploration possible.

Source | NASA

Moon

The overarching program to return humans to the moon is named after Artemis, the Greek goddess of the moon and the hunt, the twin sister of Apollo — and the scope of the program is vast. Artemis will establish a lunar-orbit base, allowing astronauts to not only further explore the moon, but also use the moon as an outpost for eventual missions to Mars. Several projects make up the Artemis program, including a new heavy launch system known as the Space Launch System (SLS), the Orion crew vessel, a lunar orbit space station known as Gateway and a lunar lander. Advanced composites factor into all of these components in one way or another.

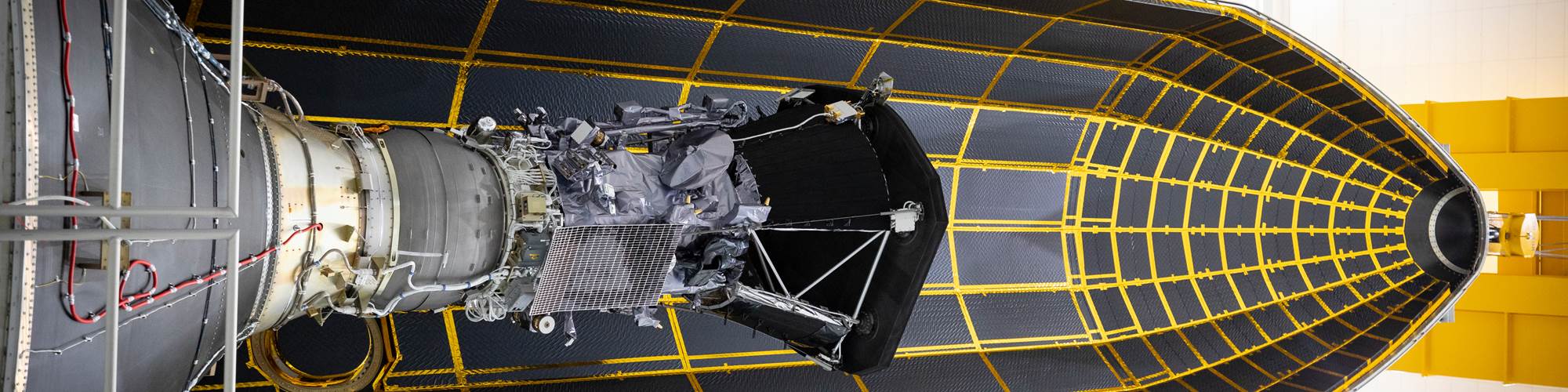

Heavy launcher. SLS Rocket Stage being prepared for shipping. Source | NASA

The Space Launch System (SLS)

NASA’s new heavy launch vehicle is aimed at enabling exploration beyond Earth’s orbit. In 2015 NASA invested in an Electroimpact (Mukilteo, Wash., U.S.) automated fiber placement (AFP) machine to manufacture large-scale rocket parts comprising sandwich structures of more than 8 meters in diameter made of carbon fiber skins with an aluminum honeycomb core. The AFP head holds up to 16 spools of carbon fiber and is positioned at the end of a 21-foot robot arm that places the fibers onto a tooling surface in precise patterns to form structures of varying shapes and sizes.

Similar sandwich structures are created by RUAG Space (Decatur, Ala., U.S.; renamed to Beyond Gravity) using a manual layup process. The company is working with Dynetics (Huntsville, Ala., U.S.) on a Universal Stage Adapter (USA) that will join the upper stage of SLS to the Orion crew module. RUAG Space will manufacture the adapter’s 8.4-meter-diameter shell comprising four composite honeycomb core quarter panels that will be hot-bonded together (Learn more).

Crew module. The Orion spacecraft being prepared for thermal testing. Source | NASA

The Orion Multi-Purpose Crew Vehicle

Consisting of a command module manufactured by Lockheed Martin (Bethesda, Md., U.S.) and a service module provided by the European Space Agency (ESA, Paris, France) and manufactured by Airbus Defence and Space (Ottobrunn, Germany), Orion is the heart of the Artemis program and will carry astronauts to space, serve as the exploration vehicle during space travel and return the crew to Earth.

Solid rocket motor case. Aerojet Rocketdyne is using a new carbon fiber winding machine to produce solid rocket motor cases at its Huntsville, Ala., U.S., Advanced Manufacturing Facility. Source | Aerojet Rocketdyne

Orion’s propulsion system includes numerous components manufactured by Aerojet Rocketdyne (Sacramento, Calif., U.S.), including eight 110-pound thrust biopropellant auxiliary engines based on Aerojet Rocketdyne's R-4D engine family. Aerojet Rocketdyne also provides the the Launch Abort System (LAS) jettison motor and composite overwrapped pressure vessels for the spacecraft. In early 2020, Aerojet Rocketdyne installed a carbon fiber winding machine to produce its solid rocket motor cases (Learn more).

Heat shield. Orion’s carbon fiber heat shield is manufactured using an out-of-autoclave prepreg from Toray Advanced Composites. Source | Lockheed Martin

For reentry, Orion uses a 5-meter diameter carbon fiber heat shield manufactured by Lockheed Martin that is manufactured as a sandwich structure featuring carbon fiber skins and a titanium honeycomb core. The heat shield is then covered in panels of Avcoat — the same ablative material used for the Apollo missions (Learn more).

Four compression pads of ablative material are attached to the heat shield with titanium bolts at points where the command module attaches to the service module. The compression pads must resist structural loads during launch and ascent, as well as pyro-shock (from explosive bolts) during the separation of the two modules. They must also meet reentry demands for high-temperature resistance and ablation. Carbon fiber/phenolic pads were used on the first flight Orion test vehicle, but showed evidence of inter-laminar cracks post flight and were replaced with a 3D woven solution known as 3D Multifunctional Ablative TPS (3D-MAT) that uses a 3D woven quartz material from Bally Ribbon Mills (Bally, Pa., U.S.) and a cyanate ester resin system from Toray Advanced Composites (Learn more).

Orion compression pad. Source | NASA

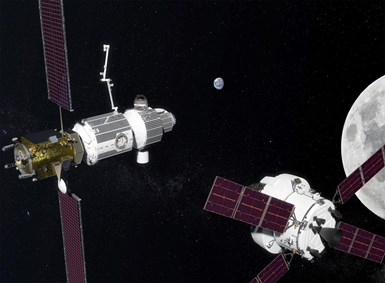

Gateway. Artists rendering shows Orion in the process of docking with the Lunar Orbital Platform-Gateway. Source | NASA

The Lunar Orbital Platform-Gateway (LOP-G)

Gateway is a lunar-orbit space station being developed by NASA along with international partners including Russian, Canadian, Japanese and European space agencies. Gateway's role is to support exploration of the moon and to serve as outpost for eventual missions to Mars. The various modules for the station are in development and will likely employ composite materials in some fashion.

A Roll-Out Solar Array (ROSA) developed by the Air Force Research Laboratory (AFRL; Dayton, Ohio, U.S.) and Deployable Space Systems using high-strain composites (HSC) will be used in the Gateway program. HSCs are thin, lightweight composite materials engineered to fit into small packages and deploy by unfurling. The ROSA system uses two carbon fiber HSC booms to roll out and tension a large solar array blanket. (Learn more about HSCs).

Another potential contribution to Gateway is the Canadarm-3. Proposed by the Canadian Space Agency (Longueuil, Quebec, Canada), the device is a 8.5-meter robotic arm built from carbon fiber composites. Previous Canadarm systems have been used on the space shuttle and the International Space Station (ISS).

Lunar landers

Numerous companies are working on lunar landing system concepts for Artemis, all of which include potential for composite materials. For example, Blue Origin (Kent, Wash., U.S.) is partnering with Lockheed Martin, Northrop Grumman (Falls Church, Va., U.S.) and Draper (Cambridge, Mass., U.S.) on a proposed three-vehicle lunar landing system: Blue Origin’s Blue Moon lunar lander, a “Transfer Element” vehicle provided by Northrop Grumman that will position the landing system in lunar orbit, and an “Ascent Element” vehicle provided by Lockheed Martin that will return astronauts to lunar orbit from the moon’s surface. A descent guidance system and flight avionics will be provided by Draper. Several other companies working on lunar lander concepts include Boeing, Dynetics, SpaceX and Sierra Nevada Corp. (Louisville, Colo. and Madison, Wis., U.S.).

In addition to crewed lunar landers, NASA anticipates the need for both small and mid-size lunar landers to enable a variety of science investigations and large technology demonstration payloads.

Artemis xEMU. NASA’s new EVA suit provides improved range of mobility. Source | NASA

Artemis suits

In October 2019, NASA unveiled two new spacesuit designs — a new Exploration Extravehicular Mobility Unit (xEMU) and the Orion Crew Survival System (OCSS) suit — both of which will be used for the Artemis program moon missions.

The xEMU suit is reported to offer a much improved range of mobility over suits currently in use for extravehicular activity (EVA). According to ILC Dover (Frederica, Del., U.S.), who has longstanding relationship with NASA manufacturing space suits, the xEMU suit is an update of an advance walking suit delivered to NASA in 2016 known as the Z-2.

“Since 2016, ILC Dover has continued to improve the design of walking suits, as well as zero-g suits and launch entry suits,” says Dan Klopp, product marketing for ILC Dover.

The Z-2 spacesuit prototype features a carbon/epoxy torso and hip elements in the design. (See "On Mars, not just any suit will do” for more on composites use in spacesuits.)

NASA’s OCSS spacesuit is designed as a pressurized launch and entry suit for Orion crew members. While NASA has not released details on the materials in the new design, it’s a safe bet that a fair amount composites are involved. Shuttle-era launch and entry suits featured an outer layer of DuPont’s (Richmond, Va., U.S.) flame-resistant meta-aramid Nomex. Previous Extravehicular Mobility Units (EMUs) have used combinations of Nomex, the para-aramid Kevlar (also developed by DuPont) and Gore-Tex, a waterproof, breathable fabric membrane manufactured by W.L. Gore & Assoc. (Newark, Del., U.S.) (Learn more).

Mars. Source | NASA

Mars

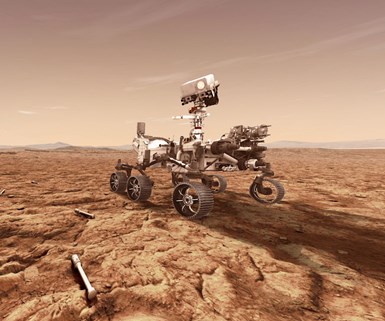

Rover. The Mars 2020 rover will weigh less than the average compact car. Source | NASA

A large part of the Artemis initiative is setting the stage to send humans to Mars. In the meantime, NASA also is working toward an unmanned mission to Mars this summer that will establish a new robotic rover and a robotic exploratory helicopter on the red planet.

Aeroshell. The aeroshell is designed to protect the Mars rover during atmospheric entry and landing. Source | Lockheed Martin

A capsule-shaped aeroshell will protect the Mars 2020 rover during entry into Mars’ atmosphere and landing. The aeroshell is made of an aluminum honeycomb with carbon fiber skins. The heat shield uses a tiled phenolic impregnated carbon ablator (PICA) thermal protection system.

Mars helicopter. More than 1,500 individual pieces of carbon fiber were used in the construction of the Mars helicopter. Source | NASA

The Mars 2020 Rover itself is approximately 10 feet long, 9 feet wide and 7 feet tall (3 meters long, 2.7 meters wide, 2.2 meters tall). While NASA hasn’t released details about the materials used to construct the rover, it is known that Advanced Composites Training (ACT, London, Ontario, Canada) served as a consultant to NASA’s Jet Propulsion Laboratory (JPL, Pasadena, Calif., U.S.) on the use of composite materials for construction of the Mars 2020 rover (Learn more).

At 2,314 pounds (1,050 kilograms), the rover will weigh less than the average compact car. It needs to be both lightweight and durable for the journey to the red planet, and also needs to be strong enough to carry cameras and scientific instruments, as well as the Mars Helicopter — another composites-intensive craft that will be used to explore the planet.

The Mars Helicopter is constructed of more than 1,500 individual pieces of carbon fiber, flight-grade aluminum, silicon, copper, foil and foam and weighs no more than 4 pounds (1.8 kilograms) (Learn more).

Sun. Source | NASA

Sun

Two missions are currently underway to improve our understanding of the sun and its behaviors, both with the ultimate goal of forecasting solar storms that can affect terrestrial electrical systems, satellite communications and GPS.

Solar probe. Parker Solar Probe’s carbon fiber composite foam TPS is designed to withstand the heat of the sun's corona. Source | NASA

Parker Solar Probe

The Parker Solar Probe launched in August 2018 and performs in-situ measurements and imaging to study the corona of the sun and solar wind. In order to endure the extreme temperatures in this region, the probe uses a 4.5-inch-thick lightweight reflective shield. This thermal protection system (TPS) is made from carbon fiber composite foam sandwiched between two carbon laminates and coated with white ceramic paint on the sun-facing surface. The shield was designed by Johns Hopkins Applied Physics Laboratory (Laurel, Md., U.S.) and built at Carbon-Carbon Advanced Technologies (Kennedale, Texas, U.S.).

Most of the probe’s instruments are tucked behind the TPS, and sensors along the edge of the heat shield keep the spacecraft positioned correctly. Solar arrays that are used to power the craft can be retracted into the heat shield’s shadow for protection. A simple cooling system that operates by circulating about a gallon of water is also employed to keep the solar arrays and instrumentation cool.

In January 2019, NASA reported that Parker Solar Probe was operating as designed following its fourth close approach to the sun, known as a perihelion. The craft’s TPS reached a new record temperature of 1,134º F (612º C), though the spacecraft and instruments behind this protective heat shield remained at a temperature of about 85º F (30º C). During the spacecraft’s closest three perihelia in 2024-25, the TPS will see temperatures around 2,500º F (1,370º C).

Solar shield. A carbon fiber composite/titanium layered solar shield protects the Solar Orbiter from the heat of the sun. Source | ESA

Solar Orbiter

Solar Orbiter, a collaborative mission between the European Space Agency (ESA) and NASA , launched in February 2020. The orbiter is on a unique trajectory that will allow its comprehensive set of instruments to provide the first-ever images of the sun's poles.

The spacecraft is protected by a carbon fiber composite/titanium layered solar shield with apertures for various instruments. The 324-pound heat shield can withstand up to 970º F (521º C) and uses a 0.05-millimeter-thick layer of titanium foil to reflect heat. The shield is supported by a 2.94-by-2.56-meter support panel that is about 5 centimeters thick and made of lightweight aluminum honeycomb with two high thermal conductivity carbon fiber skins. Further protection is provided by multi-layer insulation capable of withstanding 572º F (300 °C). Solar Orbiter’s heat shield is coated with a thin, black layer of calcium phosphate.

Space telescope. Using infared light, the James Webb Space Telescope will allow astronomers to observe the most distant objects in the universe. Source | NASA

Beyond the solar system

In August 2019, engineers at Northrop Grumman’s facilities in in Redondo Beach, Calif., U.S., mechanically connected the James Webb Space Telescope’s (JWST) Optical Telescope Element, which includes mirror and science instruments, and the Space Craft Element, which combines JWST’s sunshield and spacecraft, for the first time. Although both components of the telescope have been tested individually, this marks the first time the two halves have been combined into a single observatory. The milestone was an important one for Webb as the telescope inches toward its planned launch in 2021.

JWST is the most powerful and complex space telescope ever built — 100 times more powerful than the Hubble telescope. Designed to explore the cosmos using infrared light, the telescope will allow astronomers to observe the most distant objects in the universe, providing images of distant stars, exoplanets and the first galaxies formed. The telescope is also an exciting example of how composites enable satellites and spacecraft.

The telescope platform is made up of three major components — the Optical Telescope Element (OTE), the Integrated Science Instrument Module (ISIM), and the Space Craft Element (SCE), which includes the spacecraft bus and the tennis-court sized sunshield.

JWST employs a carbon fiber backplane to support the telescope’s mirrors, instruments and other elements — a total of more than 2,400 kilograms (2.5 tons) of hardware. The structure is also responsible for keeping the telescope steady during long periods of light collection. The backplane cannot vary more than 38 nanometers despite extreme temperatures ranging from -406°F to -343°F (-243°C to -208°C).

The backplane is made from prepreg comprising carbon fiber provided by Toray Advanced Composites and cyanate ester resin from Hexcel (Stamford, Conn., U.S.). The structure includes more than 10,000 lightweight carbon fiber composite parts. The entire backplane structure includes the center section, the wing assemblies and the backplane support fixture (BSF), and measures approximately 24 feet tall by 19.5 feet wide by more than 11 feet deep (7.3 by 5.9 by 3.4 meters) when fully deployed. It weighs only 2,180 pounds (989 kilograms), but will support instruments weighing more than 7,300 pounds (3,311 kilograms) — a payload of more than 300% its own weight.

In addition to the primary mirror and backplane structure, JWST's OTE includes its Deployable Tower Assembly (DTA), the secondary mirror support structure and the ISIM framework that houses the telescope’s scientific instruments and cooling systems. These structures are made with a prepreg of ultra-high modulus carbon fiber and cyanate ester resin from Toray Advanced Composites.

“These materials are very good optical bench materials,” says Sean Johnson, product manager, thermosets for Toray. “The high stiffness of the UHM fiber provides a very stable structure [and] provides a certain amount of damping. It’s very good at the low temperatures [JWST] is going to see.”

The SCE, or spacecraft bus, is also made of Toray’s carbon fiber composites and houses the spacecraft’s propulsion, observatory support systems, solar power, active cooling systems and communications. The bus must simultaneously be lightweight yet capable of withstanding a force equivalent to 45 tons while supporting the observatory during launch.

In October 2019, JWST successfully passed its sunshield deployment testing and is currently scheduled to launch in 2021. (Learn more).

A giant leap

The next few years will set the stage for a whole new age of space exploration. As the spacecraft and systems needed for this new golden age continue to evolve, composites suppliers and fabricators will be constantly challenged to push the materials and technologies to new limits.

Related Content

VIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More