Ketones

Magma Global delivers high-pressure composite riser pipe to HWCG consortium

Carbon fiber-reinforced thermoplastic m-pipe designed for flexible and more rapid deepwater oil and gas emergency responses for the U.S. Gulf of Mexico.

Read MoreOhio State CDME advances AM technology with Cincinnati Inc. MAAM printer

With an additive machine that prints ULTEM, PEEK and PEKK thermoplastics, university researchers and students expect to take 3D printing to new heights, including printing a fully functional turbine and internal combustion engines.

Read MoreIn-house polymer pulverizer expands Ensinger’s manufacturing capacities for composites

Machine investment strengthens Ensinger’s position as a complete solution provider in the areas of thermoplastic composite products and services.

Read MoreWing of Tomorrow ribs: One-shot, thermoplastic, OOA consolidation

GKN Aerospace’s carbon fiber thermoplastic aircraft rib design accomplishes 45-minute cycle times, reduced weight and competitive costs via a customized press system.

Read MoreImpossible Objects, Ricoh 3D partner to produce high-strength 3D-printed composite parts

New material options for industrial customers across Europe to remove barriers to printing parts for drones, aircraft, automobiles, athletic gear and more.

Read MoreENLIGHTEN program launched to speed thermoplastic composites industrialization

Multi-scale modeling, testing, sensors and machine learning will advance understanding and algorithms to achieve process control and optimization for both aerospace and automotive supply chains.

WatchMaruHachi installs new UD tape line for high-end applications

New focus on high-temperature thermoplastic tapes and multi-layer sheet laminates for aerospace, automotive and other demanding market segments.

Read MoreBoston Materials manufacturing line increases composite material production capacity

Boston Material’s new 60-inch-wide roll-to-roll manufacturing line increases production capacity of Z-axis carbon fiber materials to more than eight million square feet per year.

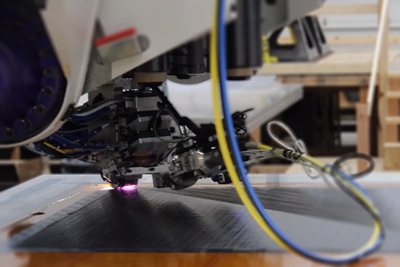

Read MoreVictrex, Electroimpact achieve thermoset AFP speeds using thermoplastics

Using Electroimpact’s AFP technology and Victrex’s low-melt PAEK prepreg tape, the companies report laydown speeds of 4,000 inches per minute.

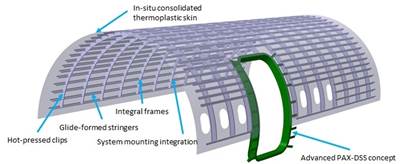

Read MoreManufacturing the upper half of the Multifunctional Fuselage Demonstrator (MFFD)

Proving industrial reliability for low-cost thermoplastic composites production using AFP in-situ consolidation, as well as continuous ultrasonic and resistance welding.

Watch