Boston Materials manufacturing line increases composite material production capacity

Boston Material’s new 60-inch-wide roll-to-roll manufacturing line increases production capacity of Z-axis carbon fiber materials to more than eight million square feet per year.

All photo credit: Boston Materials

On Feb. 9, Boston Materials (Bedford, Mass., U.S.), a manufacturer of advanced lightweight materials, started shipping Z-axis carbon fiber products made with its new 60-inch-wide roll-to-roll manufacturing line to customers in North America and Europe.

“Demand for our Z-axis carbon fiber products is accelerating across several transportation, electronics, industrial and consumer markets,” says Anvesh Gurijala, Boston Materials CEO. “The launch of our new industrial-scale production line demonstrates our ability to quickly scale to support our growing customer base.”

According to Boston Materials COO, Michael Segal, the manufacturing line features state-of-the-art and fully automated inline quality tracking for 100% traceability and quality assurance.

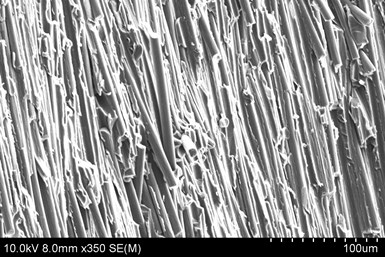

The first shipments include the company’s Supercomp reinforcement product, a high-performance 3D carbon fiber material that is designed to enhance vibration damping, energy dissipation and manufacturability of lightweight composite structures.

Boston Materials also announces the limited release of its ZRT thermoplastic composite films leveraging high-performance polymers such as polyetheretherketon (PEEK), polyethylenimine (PEI), polyphenylene sulfide (PPS), polycarbonate and more. This new product, also produced with the 60-inch-wide manufacturing line, has been designed to enhance thermal management, EMI shielding and through-thickness mechanical properties in electric vehicle, consumer electronics and aerospace applications. Boston Materials says ZRT films are made with 100% reclaimed carbon fiber to support sustainability and circularity targets.

The company plans to install at least two more 60-inch-wide manufacturing lines over the next three years in its recently opened 37,000-square-foot manufacturing facility in Billerica, Mass, U.S.

Related Content

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.