Victrex, Electroimpact achieve thermoset AFP speeds using thermoplastics

Using Electroimpact’s AFP technology and Victrex’s low-melt PAEK prepreg tape, the companies report laydown speeds of 4,000 inches per minute.

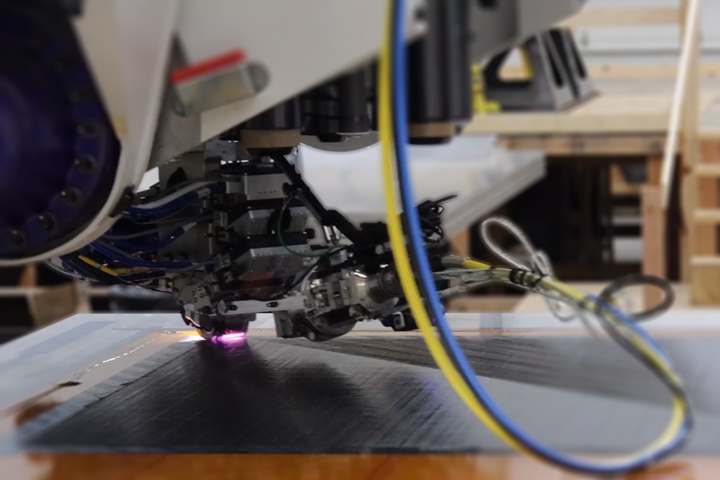

Photo Credit: Victrex

In a step toward the production of large-scale aerospace components from thermoplastic composites, polymer solutions provider Victrex (Cleveleys, U.K.) and automation and tooling specialist Electroimpact (Mukilteo, Wash., U.S.) recently announced that they have achieved laydown speeds of 4,000 inches per minute (IPM) using Electroimpact’s automated fiber placement (AFP) technology and VICTREX AE 250 low-melt polyaryletherketone (LMPAEK) unidirectional (UD) tape.

The Electroimpact AFP processing technology has been enhanced with the deployment of a new laser heating system; VICTREX AE 250 UD tape is a high-performance thermoplastic composite prepreg tape that was designed by Victrex to have mechanical, physical and chemical resistance properties typical of the polyaryletherketone (PAEK) polymer family, such as PEEK, but with a 40°C lower crystalline melting temperature, at 305°C.

“The significance of processing thermoplastic UD tape at 4,000 IPM layup speeds with [Electroimpact’s] Variable Spot Size (VSS) Laser is, for the first time that we know of, that thermoplastics are able to achieve thermoset layup speeds. These developments can help eliminate the need for autoclave cure, and offer major, and new, throughput advantages for thermoplastics.” explains Michael Assadi, chief engineer at Electroimpact.

According to James Myers, head of R&D at Victrex, “The low-melt technology is the key differentiator in optimizing for AFP.” The 305°C melt temperature of this product, in particular, he adds, “enables the high-performance properties of other PAEK polymers at lower energy on the laser, with the right consolidation levels for aerospace. Additionally, the UD tape’s extremely high impregnation, consistency in terms of width and thickness and long continuous lengths without splices are factors contributing to fast layup.”

According to Myers, this product is being optimized for manufacturing efficiency in several automated processes, including AFP, automated tape laying (ATL) and continuous compression molding (CCM). “While the material platform is still in development, there is an emerging potential for large, high-performance structural applications operating in demanding environments where rapid-rate/high-volume manufacture is a key requirement,” he adds. “We have yet to find the limitations of the material in traditional AFP/ATL processing environments.”

This level of speed is currently reported for out-of-autoclave (OOA) consolidation, though according to Myers, the team is also trialing in-situ processing at Electroimpact’s facility, “to create porosity-free laminates in one step.” To this, Assadi adds, “In terms of speed, in-situ consolidation is limited by the material crystallization and autohesion to achieve required properties. The throughput/efficiency benefit of course is that there is no additional consolidation step.”

Victrex reports that a test program comparing several different materials demonstrated that the Victrex LMPAEK UD tape delivered the best performance, producing porosity-free laminations, including the most dimensionally uniform and even distribution of fiber in the resin.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

.jpg;width=70;height=70;mode=crop)