Materials

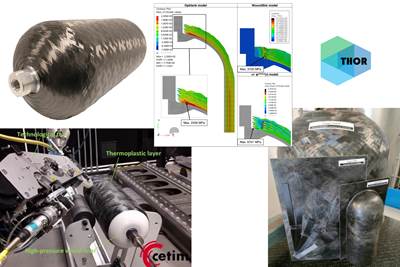

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

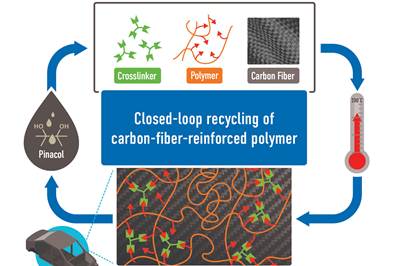

Read MoreORNL develops dynamically crosslinked CFRP, enabling closed-loop recycling

At laboratory scale, functionalized CFRP thermosets can be “released” via heat or chemicals to reincarnate them back into their starting materials.

Read MoreRepurposing wind blades as functional community art pieces

Ohio-based Canvus Inc. upcycles fiberglass wind blades, car tires and post-consumer plastics to create outdoor furniture that amplifies sustainability messages in community spaces.

WatchEve selects composite seats from Recaro Aircraft for 2026 eVTOL

The delivery, to include 75,000 GFRP seats, marks Recaro’s entry into the AAM market.

Read MoreFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

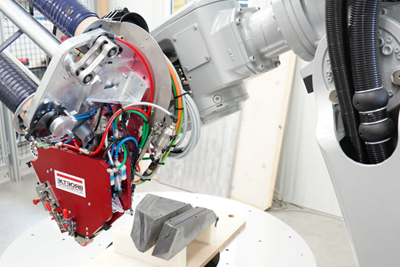

Read MoreBroetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Read MoreHyfer Objects furniture incorporates Sulapac wood composites

High-end design furniture is 3D printed from bio-based, eco-friendly materials for aesthetic and sustainable home product options.

Read MoreToray celebrates commissioning of expanded Torayca T1100 production line

Doubled carbon fiber production capacity at Toray’s Decatur, Alabama, plant will support rising demand in U.S. defense.

Read MoreCRP Technology launches Windform SL for UAV needs

Carbon fiber-reinforced polyamide, added to CRP’s Top-Line series, is well suited to demands for lightness, stiffness and thermal resistance in composites 3D printing.

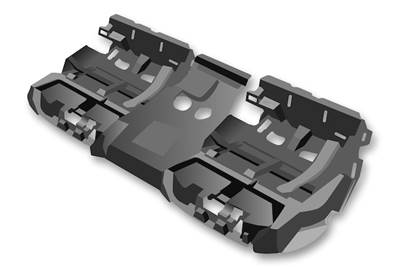

Read MoreComposites, resins portfolio supports EV applications, sustainability

JEC World 2024: Huntsman is sharing a new polyurethane- and epoxy-based composites portfolio aligned with the needs of the automotive sector.

Read More