ORNL develops dynamically crosslinked CFRP, enabling closed-loop recycling

At laboratory scale, functionalized CFRP thermosets can be “released” via heat or chemicals to reincarnate them back into their starting materials.

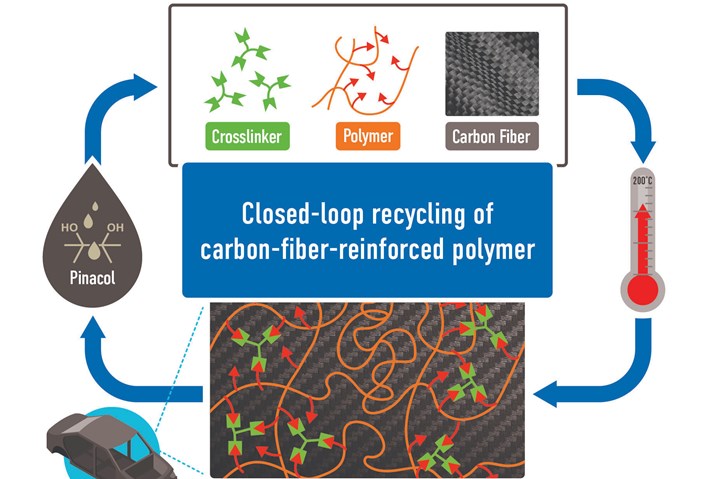

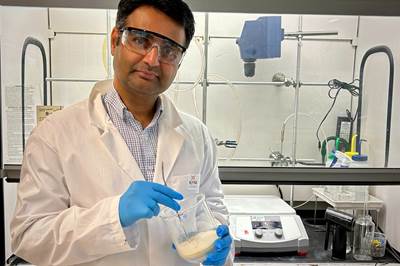

A polymer, functionalized carbon fibers and a crosslinker are mixed and cured. The components can be retrieved by addition of an alcohol, pinacol. Source | Philip Gray and Anisur Rahman/ORNL, U.S. Dept. of Energy

Inventors at the Department of Energy’s (DOE) Oak Ridge National Laboratory (Oak Ridge, Tenn., U.S.) have designed a closed-loop path for synthesizing an exceptionally tough carbon fiber-reinforced polymer (CFRP) and later recovering all of its starting materials. The findings, published in Cell Reports Physical Science, are said to accelerate addressing the challenge of recycling conventional CFRPs, which have typically been single-use materials.

“We incorporated dynamic crosslinking into a commodity polymer to functionalize it. Then, we added a crosslinker to make it like thermoset materials,” explains ORNL chemist and inventor Md Anisur Rahman. “Dynamic crosslinking allows us to break chemical bonds and reprocess or recycle the carbon fiber composite materials.”

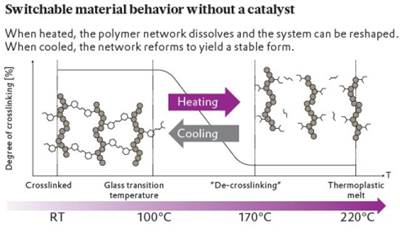

A conventional thermoset material is permanently crosslinked. Once synthesized, cured, molded and set into a shape, it cannot be reprocessed. ORNL’s system, on the other hand, adds dynamic chemical groups to the polymer matrix and its embedded carbon fibers. The polymer matrix and carbon fibers can undergo multiple reprocessing cycles without loss of mechanical properties, such as strength and toughness.

Rahman led the study with ORNL chemist Tomonori Saito. Rahman and ORNL postdoctoral fellow Menisha Karunarathna Koralalage conducted most of the experiments. The trio has applied for a patent for the innovation.

“We invented a tough and recyclable carbon fiber composite,” says Saito. “The fiber and the polymer have a very strong interfacial adhesion due to the presence of dynamic bonds.” The interface locks materials together through covalent interactions and unlocks them on demand using heat or chemistry.

The novel CFRPs’ tensile strength, was the highest ever reported among similar fiber-reinforced composite materials, ORNL researchers contend, at 731 megapascals.

Conventional polymers like thermoset epoxies are typically used to permanently bonded materials such as metal, carbon fiber, concrete, fiberglass, ceramic and plastics to form composites. However, in the ORNL material, the polymer, carbon fibers and crosslinker, once thermoset, can be reincarnated back into those starting materials. The material’s components can be released for recycling when a special alcohol called a pinacol replaces the crosslinker’s covalent bonds.

Closed-loop recycling at laboratory scale resulted in no loss of starting materials. “When we recycle the composites, we recover 100% of the starting materials — the crosslinker, the polymer, the fiber,” emphasizes Rahman, noting that other composite recycling technologies tend to lose the component starting materials.

Inspiration for the solution was originally drawn from nature, such as nacre, the iridescent mother-of-pearl inside the shells of marine mussels and other mollusks, is exceptionally tough: it can deform without breaking. “Our composite’s strength is almost 2 times higher than a conventional epoxy composite,” says Rahman. Other advantages of the reversibly crosslinked CFRPs include quick thermosetting, self-adhesive behavior and repair of microcracks in the composite matrix.

Moreover, the novel CFRPs’ tensile strength, was the highest ever reported among similar fiber-reinforced composite materials, ORNL researchers contend, at 731 megapascals — stronger than stainless steel and stronger than a conventional epoxy-based CFRP composite for automobiles.

The ORNL material’s dynamic covalent bonding between the fiber interface and the polymer also had 43% greater interfacial adhesion compared to polymers without dynamic bonds.

To achieve this material, Karunarathna Koralalage, Rahman and Saito modified a commodity polymer, called S-Bpin, with assistance from Natasha Ghezawi, a graduate student at the Bredesen Center for Interdisciplinary Research and Graduate Education of the University of Tennessee, Knoxville. They created an upcycled styrene ethylene butylene styrene copolymer, which incorporates boronic ester groups that covalently bond with a crosslinker and fibers.

Because CFRP is a complex material, its detailed characterization required diverse expertise and instrumentation. ORNL’s Chris Bowland tested tensile properties. With Raman mapping, ORNL’s Guang Yang showed the distribution of chemical and structural species. Catalin Gainaru and Sungjin Kim, both of ORNL, captured rheological data and Alexei Sokolov, a UT-ORNL governor’s chair, elucidated it. Scanning electron microscopy by Bingrui Li, of ORNL and UT, revealed that carbon fiber maintained its quality after recycling. UT’s Vivek Chawla and Dayakar Penumadu analyzed interlaminar shear strength. With X-ray photoelectron spectroscopy, ORNL’s Harry Meyer III confirmed what molecules attached to fiber surfaces. ORNL’s Amit Naskar, an expert in carbon fiber, reviewed the paper.

The scientists found that the degree of dynamic crosslinking is important. “We found 5% crosslinking works better than 50%,” says Rahman. “If we increase the crosslinker amount, it starts making the polymer brittle. That’s because our crosslinker has three hand-like bulky structures, able to make more connections and decrease the polymer’s flexibility.”

Next, the research team would like to conduct similar studies with glass fiber composites. They also hope to reduce costs of the new technology to optimize commercial prospects for a future licensee. “This step will open more applications, especially for wind turbines, electric vehicles, aerospace materials and even sporting goods,” adds Rahman.

The Vehicle Technologies Office in DOE’s Office of Energy Efficiency and Renewable Energy sponsored the research. DOE’s Office of Electricity sponsored Raman mapping.

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

Reversibly crosslinking thermoset-thermoplastic hybrid polymers

Evonik’s new system delivers crosslinked performance of epoxies below 100°C, processing benefits of thermoplastics above 170°C.

Read MoreComposite current collectors to enable EV battery efficiency

Researchers at ORNL have developed a metal-free current collector using carbon fiber and nanotubes to further lightweight lithium-ion batteries and increase energy density, improving EV driving range.

Read MoreXlynX Materials introduces PFAS-free BondLynx molecular adhesive

Improved version of BondLynx eliminates fluorine for a more sustainable adhesive option, while still outperforming conventional adhesive bonding strength.

Read More