Materials

Aeroengine Composites, Part 2: CFRPs expand

Proven in fan blade/case applications, carbon fiber-reinforced polymers migrate to previously unanticipated destinations nearer the engine “hot zone.”

Read MoreComposites upgrade marine infrastructure

All-composite docks best concrete in cost and time and aim toward future fastener-less construction for greater savings and sustainability.

Read MoreAutomotive composites: Thermosets for the fast zone

Epoxies continue to be developed for faster cure to meet automotive production rates.

Read MoreComposite brackets for life-of-aircraft service

Reinforced PEEK molding formulated for jet fuel/hydraulic fluid immersion.

Read MoreOuter space: The “final frontier” is exciting again!

CW contributor Dale Brosius, a composites industry consultant and the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI), points to evidence that the composites industry will, once again, be the beneficiary of renewed drive for space exploration.

Read MoreAutomated preform process boosts properties and cuts cycle time

Fiber Patch Placement (FPP) achieves optimized fiber orientation for up to 150% increase in stiffness and reduced cycle time, weight and material waste.

Read MoreLooking to lighten up aircraft interiors? Try natural fibers!

Aircraft OEMs are striving to make their products more efficient, with improved engines and ever-increasing use of composite materials, including in aircraft interiors.

Read MoreLarge-format CNC routing for large CFRP parts

5-axis CNC routers can provide fast, precision machining of increasingly larger parts, but also rapid payback.

WatchComposites extend service of oil and gas pipelines

Corrosion-resistant aramid fiber/thermoplastic liner gives new life to deteriorating steel subsea pipelines.

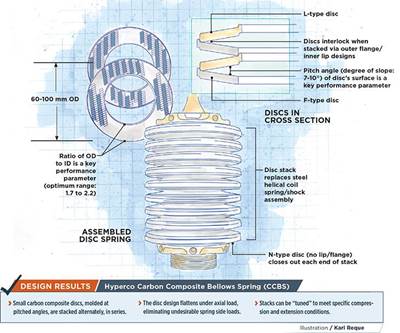

Read MoreCarbon composite spring: Big performance, small package

Disc spring stack is lighter, reduces friction and can be performance-tuned.

Read More