Materials

Collins Aerospace selected by AFRL to build thermoplastic composite fin for F-16

Part of $100 million, five-year investment to advance, qualify thermoplastic composites for military and commercial aero applications.

Read MoreCDZ Compositi introduces patented 3D Flex Composite

Specialist in structural and aesthetic prepreg press parts enhances 3D shaping and flexibility in composite parts using carbon and other reinforcement fibers.

WatchForvia brand Faurecia exhibits XL CGH2 tank, cryogenic LH2 storage solution for heavy-duty trucks

Part of its full hydrogen solutions portfolio at IAA Transportation 2022, Faurecia also highlighted sustainable thermoplastic tanks and smart tanks for better safety via structural integrity monitoring.

Read MoreTri-Mack introduces thin, lightweight thermoplastic composite enclosures

Durable, low-cost manufacturing support wide range of industrial uses, with option for embedded EMI shielding.

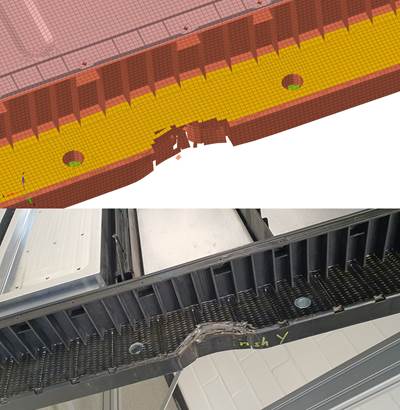

Read MoreBattery enclosure demonstrator testing proves EV feasibility, launches series production projects

Kautex Textron and Lanxess jointly developed and tested a PA6 technology demonstrator, reinforced with locally placed continuous fiber blanks, which passed all important mechanical, thermal tests.

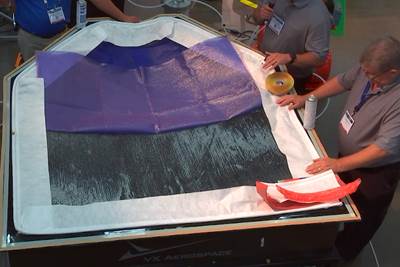

Read MoreDigital Demo: Aerospace Carbon Fiber Infusion

Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

WatchCobra Advanced Composites launches flax fiber-based visual finish components

New range of sustainable, low-density, production-ready composite components meet challenging automotive OEM standards for exterior and interior applications.

Read MoreCarbon Fiber Recycling now accepts carbon fiber bobbin waste

Carbon Fiber Recycling is capable of processing depleted carbon fiber bobbins, provides opportunities for manufacturers looking to recycle 100% of their waste stream.

Read MoreToray Composite Materials America to double Torayca T1100 production capacity

The upgrade to the company’s Decatur, Alabama, carbon fiber plant is set to begin April 2023 in order to support rising demand in defense applications.

Read MoreHexcel HexPly M9.6 prepregs receive type approval for marine use

Third-party certification guarantees lightweight composite quality, performance and consistency for more sustainable marine vessels.

Read More

.jpg;maxWidth=300;quality=90)