Digital Demo: Aerospace Carbon Fiber Infusion

Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

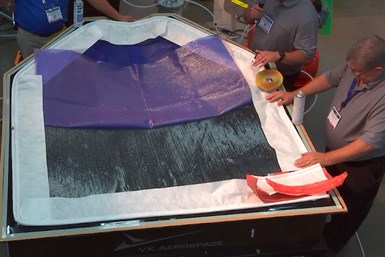

During their annual CAMX demonstration in 2021, Composites One produced a UAV wingskin part using carbon fiber and vacuum infusion. Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

Composites One also highlights their brand Aerovac, a manufacturer of process materials for vacuum infusion.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.