Molds/Tools

Hybrid analysis: Making the most of FEA by leveraging traditional analysis

CW guest columinst Collin Petersen (Janicki Industries, Sedro-Woolley, WA, US) suggests the use of more traditional analysis methods, where it is sensible to do so, making your finite element analysis (FEA) significantly simpler in the process.

Read MoreBoat builder Lyman-Morse creates aerospace composite prototype

Prototypes for such clients as the Department of Defense and other government and private sector businesses has become an increasingly important segment of the the company’s business plan.

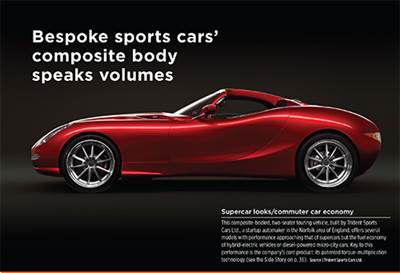

Read MoreBespoke sports cars’ composite body speaks volumes

Glass-reinforced plastic artfully captures classic curves, crash-protects passengers and stunningly packages its maker’s high-performance but highly fuel-efficient diesel powertrain.

Read MoreAdditive manufacturing in automotive applications

Although they have been overshadowed by aerospace applications, 3D-printed tools also are finding a place in automotive processing. Here's one example.

Read More3D-printed fixtures & jigs

Holding fixtures, jigs, trim tools and metal-forming dies can be expensive elements of post-mold composite part processing and assembly. Additive manufacturing, therefore, is proving especially useful in reducing the design/build time/cost in this area.

Read MoreA growing trend: 3D printing of aerospace tooling

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

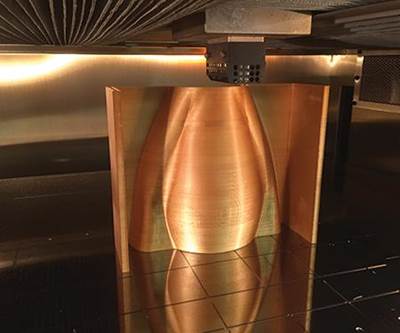

Read More3D Printing Moves Into Tooling Components

Some pundits predict that 3D printing, or additive manufacturing (AM), will change our world forever. While that may yet be, one thing is clear: The growth of 3D printing over the past two decades has wrought significant change in composites tooling. Although AM’s most obvious advantage is direct part production without tooling, the growing trend in the aerospace and automotive sectors at present is its use for fast, on-demand builds of mold tools to keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

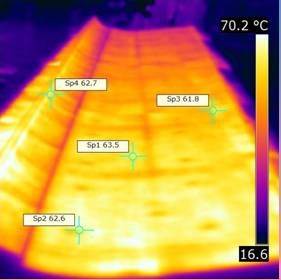

Read MoreHeated composites

LaminaHeat enables heated composite tools and new opportunities for composites via multifunctional structures.

Read MoreMassive, bondline-free tooling block

A candidate for the biggest “bun” from high-density urethane foam?

Read More