Additive manufacturing in automotive applications

Although they have been overshadowed by aerospace applications, 3D-printed tools also are finding a place in automotive processing. Here's one example.

Although they have been overshadowed by aerospace applications, 3D-printed tools also are finding a place in automotive processing. One example is the composite technical center Plateau Technique Compositic (Ploemeur, France), affiliated with the Université de Bretagné-Sud, in Ploemeur. Compositic recently displayed a large, 3D-printed composite layup tool at the JEC Europe 2015 event in Paris.

Yves Grohens, a professor at the Université, says the tool was the result of research that combined additive manufacturing (AM) with robotic automated fiber placement (AFP) and other processing technologies, with the aim to create parts as rapidly as possible. “The concept is to compress the entire part design/tool production/robotic programming and part layup time. We are currently in discussions with several automotive OEMs about this innovative use of 3D printing.”

Grohens explains that his group worked with automaker PSA Peugeot Citroën (Paris, France) on a model 208 demonstrator car roof part, in partnership with robotic system supplier Coriolis Composites Technologies (Queven, France) and SMM (Le Hezo, France), which manufactured the tool via AM. “The idea was to start from the virtual part in CAD, in the form of an .stl, .igs or other file format that is compatible with both a 3D printing machine and automated tape placement programming.”

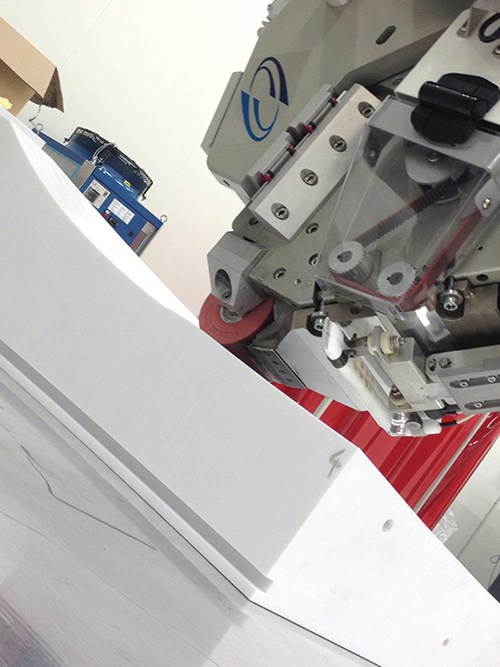

The tool’s design and shape were developed from the part’s CAD file and its print was begun by SMM, while Coriolis engineers simultaneously developed the optimum part layup and AFP machine path programming. The tool was printed on SMM’s large Fortus 900 FDM machine, supplied by AM equipment manufacturer Stratasys (Eden Prairie, MN, US), with approximately 1m3 of useful build volume. Total build time was about 100 hours.

Stratasys provided polycarbonate powder for the print build, without fiber reinforcement, but Grohens says, “We achieved sufficient stiffness and thermal stability with the polycarbonate for this demonstration tool but, in reality, it would be made with polyetherimide [PEI] Ultem material in production, to enable a higher cure temperature of 180°C and higher pressure. We limited the actual cure temperature of this demo tool to 140°C.”

Tool weight, when complete, was 14 kg. No mold treatment of any kind was undertaken after the print, says Grohens.

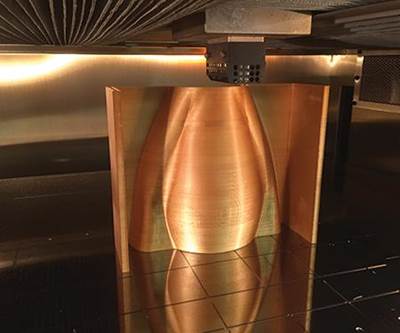

Immediately after the mold was completed, it was placed under the Coriolis robotic head to begin the part layup, using 6.5 mm wide carbon/epoxy prepreg tapes. Grohens says that the part layup process, which was completed in a day, was successful the first time, because tool build, part design and robotic processing were developed simultaneously, within the same digital space. He adds, “If we had proceeded with classical mold machining and a metallic tool, requiring test articles to ensure correct layup, this process would have taken at least two months to reach that perfect state.”

Although the untreated mold caused no problem for the part layup and cure, he does add, “The tool surface is a little bit rough, so on subsequent tools, we treat the surface with an epoxy coating that reduces the roughness and provides a better part surface finish.”

Compositic is pursuing similar projects with partners, including Airbus, for 3D-printed tool applications.

This short article is a sidebar to a longer feature article titled "A growing trend: 3D printing of aerospace tooling" and a companion to another sidebar titled "3D-printed fixutres & jigs." (To read either, click on its title under "Editor's Picks.")

Related Content

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreNine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

Read MoreRead Next

A growing trend: 3D printing of aerospace tooling

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

Read More3D-printed fixtures & jigs

Holding fixtures, jigs, trim tools and metal-forming dies can be expensive elements of post-mold composite part processing and assembly. Additive manufacturing, therefore, is proving especially useful in reducing the design/build time/cost in this area.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More