Molds/Tools

Water tree: Single complex mold shapes unique composite sculpture

To fabricate a complex design for a lighted sculpture, sculptor Lawrence Argent taps the talents of composites specialists Kreysler and Assoc. (American Canyon, Calif.).

Read MoreProper mold care: Mandatory!

CT surveys mold care product suppliers for guidance through the critical steps of mold preparation and maintenance.

Read MoreLow-volume thermoplastics: Differential pressure molding

Cost-effective tooling and presses enable semi-automated prototyping and low-volume production of thermoplastic composites.

Read MoreCabin cruiser: Making the most of a mirror finish

The hull mirror-like gel coat finish on the Daedulus 30 cabin cruiser was achieved through a combination of Marine Concepts’ (Lee-on-the-Solent, Hampshire, U.K.) mold design experience and fabrication techniques and materials provided by Scott Bader (Wollaston, Northamptonshire, U.K.).

Read MoreMaintaining fiber length in complex 3-D designs

Award-winning composite pallet showcases new LFT molding process from South Africa.

Read MoreSQRTM enables net-shape parts

New out-of-autoclave process combines resin transfer molding with prepregs for complex helicopter part prototype.

Read MoreBuilding a bigger Big Wheel

Machining specialist scales up the 1970s icon, producing plugs and tools for an exact fiberglass replica at a Disney resort.

Read MoreCost-effective carbon composite reflector dish

Modular manufacturing method forms different dish sizes with near mirror-perfect reflective surfaces, without resort to one-off tools.

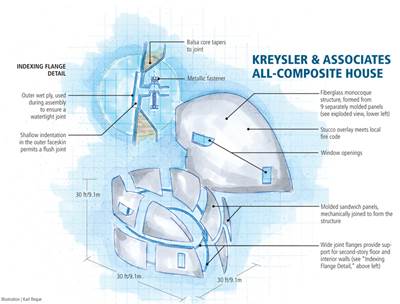

Read MoreResidential construction breakthrough: Composites find a home

Composite materials get the go-ahead for an unconventional but code-compliant California house.

Read MoreGurit CBS for the Aston Martin DBS

Out-of-autoclave process mints Class A carbon composite body panels in one-hour mold cycle.

Read More

.jpg;maxWidth=300;quality=90)