Natural Fibers

BÜFA Thermoplastic Composites offers B-PREG natural fiber-based semi-finished products

Portfolio expanded to include flax fiber/polypropylene UD prepreg tapes, woven prepregs and flax fabrics.

Read MoreNCC proposes natural fiber use for SME subterranean transport network

Under an NCC SME Boost program, research indicates composite reinforcements will reduce material, manufacturing costs and prove more sustainable for innovative SME project.

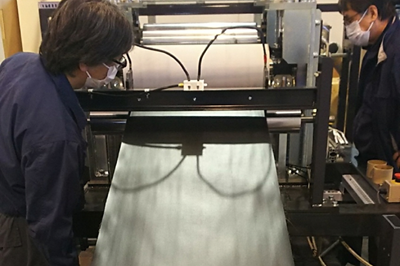

Read MoreMaruHachi installs new UD tape line for high-end applications

New focus on high-temperature thermoplastic tapes and multi-layer sheet laminates for aerospace, automotive and other demanding market segments.

Read MoreSicomin GreenPoxy resins contribute to first NFC wind turbine nacelle

Sicomin’s bio-based resins, intumescent FR gelcoats and UV-resistant clear coatings meet stringent requirements for Greenboats’ 7.3-meter natural fiber composite nacelle.

Read MoreNatural fiber-reinforced SMC targets industrial applications

Lorenz and IVW collaborate on a sheet molding compound (SMC) that can accommodate sunflower seed shells, reeds and other natural fibers and fillers.

Read MoreSuprem SA begins new pultrusion line production

Highly automated manufacturing line processes continuous fibers with high-performance thermoplastics for tapes, profiles and rods.

Read MoreLingrove launches Ekoa Surface Peel N’Stick and receives automotive orders

Natural fiber/bio-thermoplastic composite veneers meet sustainability and performance demands for multiple markets.

Read MoreTeijin contributes to sustainability with infrastructure innovations

In light of climate change and increasingly aggressive environments, Teijin focuses on new, sustainable infrastructure technologies that will enable more adaptability.

Read More3A Composites promotes sustainability initiatives

The company passed its annual FSC review, ensuring responsible balsa wood management, and confirmed Baltek SBC as a carbon-neutral core material.

Read MoreCSP Advanced Materials Center unveils composite battery enclosure and material innovations

Transition into broader R&D capabilities include honeycomb manufacturing process for ultra-lightweight Class A panels and a full-sized, multi-material battery enclosure featuring a one-piece composite cover.

Read More

.jpg;maxWidth=300;quality=90)