Natural fiber-reinforced SMC targets industrial applications

Lorenz and IVW collaborate on a sheet molding compound (SMC) that can accommodate sunflower seed shells, reeds and other natural fibers and fillers.

A rear spoiler produced with a new organic SMC. The researchers were able to fill complex ribbed structures with conventional processing parameters. They found no separation of the fiber and the matrix. Photo Credit: Institut für Verbundwerkstoffe (IVW)

An organic sheet molding compound (SMC) that can accommodate natural fillers and fibers — like ground sunflower seed shells and reeds — has been developed by Lorenz Kunststofftechnik GmbH (Wallenhorst, Germany), a producer of semi-finished polymer products for a variety of industries, and the Leibniz-Institut für Verbundwerkstoffe (IVW, Kaiserslautern, Germany), a non-profit research institution of the state of Rhineland-Palatinate and the Technical University of Kaiserslautern that specializes in composites development and processing. The goal is development of a thermoset composite with a relatively small CO2 footprint.

Peter Ooms, director of sales and business development at Lorenz, says, “We assisted the IVW with our expertise and SMC materials, as well as in the subsequent testing for industrial production. The Kaiserslautern institute did the lab-scale preliminary testing, general research and the development of the formulations for the new organic SMC.”

Potential users surveyed

In collaboration with the Institut für Verbundwerkstoffe (IVW), Lorenz Kunststofftechnik GmbH researched ways to make a thermoset composite with a lower CO2 footprint. Pictured is IVW’s SMC production line.

Photo Credit: IVW

The two organizations developed a materials specification sheet based on a survey of 30 companies in various industries including electrical, automotive and industrial equipment. “Our survey showed that different industries have different requirements for the material,” Ooms says. However, almost all wanted it to have a life-cycle assessment (LCA) to document environmental aspects and CO2 reduction in production, as well as recyclability. We chose the possible organic materials for SMC production based on these requirements.”

The partners decided to develop a glass fiber SMC that partially comprises an organic-based filler. For the filler, several options were considered, including ground sunflower seed shells and reeds, wood flour, upcycled calcium carbonate from industrial water softening plants, and thermoset recycling material. As an additional sustainability initiative, the raw materials were sourced within 500 kilometers of Lorenz’s facility.

Research on the SMC and the fillers and how the materials could be processed was performed at the IVW. Factors considered included impregnability, density, viscosity and the availability of the raw material. The researchers worked with an unsaturated polyester (UP) resin and an anti-shrinkage additive as they developed the formulation.

Working the formulations

Next, the partners defined the parameters for a demonstrator battle component to be manufactured using the new material. “This demonstrator “helped us examine the flow and mold filling behavior of the material, and compare it with conventional SMC semi-finished products,” says Dr.-Ing. Florian Gortner, a scientist at the IVW. “Building on these results and on press rheometry testing, we built a simulation model to demonstrate the flow behavior and enable predictions about other mold geometries.”

After initial research, a baseline SMC resin paste was developed comprising an unsaturated polyester (UP) resin along with an anti-shrinking additive, magnesium oxide and an internal release agent to thicken the resin, and a color paste. This resin paste went through tests so that the researchers could understand how each of the individual components interacted within the SMC. Iterative test series of resin formulations with different fillers ultimately resulted in a number of organic filler-based resins with the desired viscosity, flow and impregnation behavior.

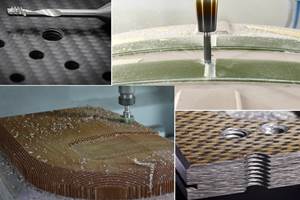

Demonstrators such as this were used to compare the new material’s flow and filling behavior with those of conventional SMC semi-finished products, including in very detailed molds. Photo Credit: IVW

Gortner says, “Magnesium oxide and an internal release agent were used to thicken the resin, and a color paste was added to color the semi-finished products. Working from the survey results, we added further additives and adapted the resin paste to the application.”

They ran several iterations of the formulations until they came up with those that feature the viscosity, flow and impregnation behavior desired. The resulting material permits the production of semi-finished products with a lower density than conventional SMC, which Lorenz hopes will be attractive to the electric vehicle market. The next step will be to produce a version of the resin commercially, which Ooms says Lorenz plans to accomplish this year.

“Now that together with IVW we have succeeded in making this new thermoset, we’re planning further improvements for practical applications,” Ooms adds. For example, Lorenz may develop iterations of the material which vary the amount of resin paste in proportion to the fillers, or substitute the glass fiber for natural fiber, depending on the application. Lorenz also says the unsaturated polyester resins could be replaced with safer, more environmentally friendly resins, as well.

According to Gortner, “The objective of our research project was to show that the use of organic-based components in semi-finished thermoset products is possible. Thanks to the active support of Lorenz, we were able to do this successfully, and will continue to incorporate feedback from industrial production into our results.”

Related Content

Notox surfboards harness flax fiber for wave surfing competition

Libeco flax, Airbus rCF fabrics, Sicomin GreenPoxy bioresins and an agave core form a heavy, robust surfboard custom-designed for Clément Roseyro in this year’s Nazaré Big Waves Surf event.

Read MoreAirbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

Read MoreEvolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreRead Next

Natural fiber composites: What’s holding them back?

Natural fiber reinforcements have been available for some time, but factors such as compatibility with current processes and geographic availability continue to limit widespread use.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;width=70;height=70;mode=crop)