Lingrove launches Ekoa Surface Peel N’Stick and receives automotive orders

Natural fiber/bio-thermoplastic composite veneers meet sustainability and performance demands for multiple markets.

After nearly a decade of research and testing, the award-winning Ekoa Surface veneer is available to consumers directly from developer and manufacturer Lingrove (San Francisco, Calif., U.S.). Ekoa is made from flax fiber, a fast-growing crop (100 days) that is CO2-negative and requires no irrigation. The strongest and stiffest natural fiber, flax is already produced on an industrial scale. Ekoa combines this high-performance fiber with bioresins to produce composite surfaces that have the look and feel of wood without the environmental drawbacks.

Ekoa Surface Peel N’Stick is used to upgrade kitchens, baths, accent walls, home offices and furniture. “We did a soft launch during this past fall because progress in our business-to-business (B2B) programs had slowed with the pandemic,” explains Joe Luttwak, Lingrove founder and president. “We had been working with companies like Steelcase, which today uses wood veneers or laminates like Formica.”

Ekoa Surface, however, has higher bio content than most of the engineered wood products being used in commercial interiors and furnishings today. “Our products have 95% bio-based content and are also Clean Air Gold certified,” says Luttwak. The latter is part of the LEED (Leadership in Energy and Environmental Design) standards developed by the Green Building Council (Washington, D.C., U.S.), which have high requirements for clean and safe chemical use in products and low carbon emissions during manufacture, installation and use. “We’ve spent years overcoming issues with natural composites and developing products that can meet very stringent demands. We now have a suite of products for architectural and design, wood replacement and automotive and other vehicle interiors, each product aligned with its market’s requirements.”

From architecture to auto interiors

“We are still working with Steelcase and others,” says Luttwak, “but the commercial interiors market has been hit hard by the pandemic. It has become a longer-term market for us. So, we launched Ekoa Surface as a consumer product. But then a Tier 1 automotive company in Europe approached us in September and soon after, we received our first purchase order from a U.S. automotive OEM for an aesthetic lightweighting application. And we now have orders from a few other Tier 1 suppliers. These applications are targeted for 2023 production models.”

These automotive companies reached out to Lingrove, says Luttwak, “seeking lightweight and sustainability that only natural composites can satisfy. Our materials also provide noise and vibration damping. We are replacing existing materials. One car company in Europe is looking for a sustainable replacement for injection molded, short fiber-reinforced plastics. These are interior applications, but they can also be for interior structures, such as floors.”

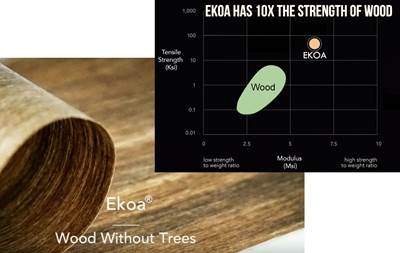

Ekoa does not compromise on performance, he adds, noting that natural composites can have a higher specific modulus than E-glass and exhibit excellent strength-to-weight properties for auto applications. Meanwhile, carbon fiber has 90 times the embodied carbon (carbon footprint, or total greenhouse gases released throughout the supply chain) compared to natural flax fiber. “If we, as the composites industry, want to make automotive a real market,” says Luttwak, “then part of that will mean embracing natural fibers and bioresins, realizing that 20% of CO2 emissions for the automotive industry comes from producing the car.”

Ekoa Surface has a further impact in automotive manufacturing. “We are saving car companies time and money by increasing part yield,” says Luttwak. “Part of that is because our materials are more moldable into compound curves and shapes than wood and metal. Another part is the high-quality finish achieved, which reduces finishing operations. The finish is key to the customer.” Ekoa Surface is available in satin, semi-gloss or gloss finish. “Tooling doesn’t impart that finish,” says Luttwak, “it comes from the material and process that we’ve developed.”

Endless markets, holistic climate solutions

Although the overall market for commercial interiors and furniture dwarfs anything in automotive, says Luttwak, “We see automotive as an excellent, near-term opportunity to have an impact on climate change, including in applications such as dashboards and seatbacks. What we are selling is still Ekoa Surface, it’s just Ekoa Surface for automotive.”

Luttwak claims Ekoa Surface transcends a specific vertical. “The possibilities are endless,” he adds. “For example, it can be used to refurbish your kitchen, upgrade a vehicle interior or create office furnishings with the look and feel of wood but at a lower cost, both in materials and to the environment. For human health, this is a win. There are no harmful chemicals, no off-gassing and no CO2 emissions. Though Ekoa Surface is still undergoing life cycle analysis (LCA), it is projected to be carbon-negative. Its lightweight means less support structure is required and less labor is needed during installation. And it offers designer aesthetics without further treatments. It is an expansive solution.”

“We need more a holistic approach toward climate change,” says Luttwak. “That is why Lingrove started working with natural composites. Trees need to be left standing to become old-growth forests, which are naturally more fire-resistant, and help us maintain groundwater and soil. People are beginning to understand the impact of their choices. Wherever you would find wood or fiber-reinforced plastic (FRP) today, that is where Ekoa can offer benefits.”

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

Bio-prepreg guitar: The look, feel, acoustic quality of wood

When the El Capitan, a composite guitar from Blackbird Guitar (San Francisco, Calif.), made its debut this year with the look and sound of a vintage instrument.

Read MoreEkoa TP, better than wood

Flax fiber/bio-thermoplastic composite provide look and feel of wood but higher properties, targeting $80 billion interiors market and, eventually, a wood replacement for construction.

Read MoreBiodegradable, biobased Ekoa composite veneers are in production

Ekoa 99.7% bio-based veneers are used to finish surfaces in walls, ceilings, furniture and vehicle interiors.

Read More