Out of Autoclave

Mining the potential of polyurethane composites

Pultruded rollers for mine conveyors outperform steel and portend a huge new market.

Read MoreResin systems update: The greening of thermosets

Thermoset resin formulators seek environmental benefits as customers demand reduced cost and increased performance.

Read MoreBridge cost cut with inflatable arches

Stay-in-place composite formwork shortens installation, doubles service life of concrete bridge structure.

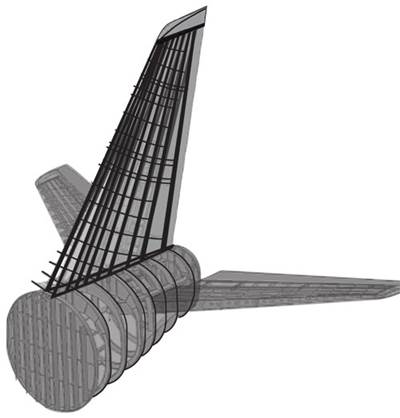

Read MoreCost- and time-saving preform process used for propeller spinner

Carbon fiber/epoxy spinner uses pulp slurry preforming process combined with vacuum infusion molding.

Read MoreThermoplastic composites: Inside story

Reinforced thermoplastics buy their way into structural aircraft interior components.

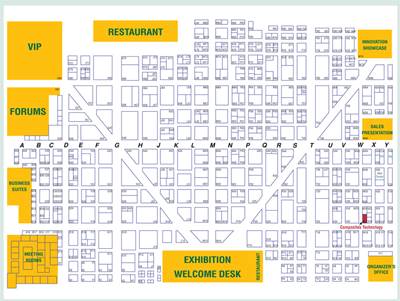

Read MoreSAMPE Europe/JEC Composites 2009 preview

SAMPE Europe’s 30th annual spring conclave and the nearby JEC Composites Show characterize the latest in material and process technologies.

Read MoreInside R and D: A-VaRTM takes flight in Japan

Tests show out-of-autoclave process can reduce costs on new regional jet.

Read MorePultruding cost out of aerospace parts

Design-for-manufacturing effort proves to be cost-effective for carbon/epoxy airfoil on expendable UAV.

Read MoreJEC Composites 2009/SAMPE Europe preview

Organizers predict good turnout in poor economy for annual Paris tradeshow.

Read MoreIs it really low-tech vs. high tech?

I’ll bet that a lot of folks who read this column regularly — assuming I’m lucky and lots of folks are reading — have spent their entire careers working with E-glass without ever thinking they were high-performance geeks, too. To them, welcome to the club!

Read More