Pultruding cost out of aerospace parts

Design-for-manufacturing effort proves to be cost-effective for carbon/epoxy airfoil on expendable UAV.

Design Results

- Production of single-use, consumable wings for weapons or UAVs is automated, using the pultrusion process.

- Wing design meets flight performance requirements despite sacrificing some aerodynamic details for more efficient, lower-cost manufacture.

- Pultrusion permits integral stiffening ribs to be incorporated into the wing in a single-step process.

The unmanned aerial vehicle (UAV) has become a potent weapon in the U.S. Armed Forces arsenal. These remotely operated “drones” have made headlines by providing military commanders a means of gathering intelligence and delivering ordnance with precision. A growing trend in the UAV market involves relatively small, single-use UAVs that, equipped with cameras and wireless communication gear and spared the concern of pilot fatigue, can loiter for days on surveillance missions and might be deployed in “swarms” to guide and protect soldiers and convoys or act as defensive decoys when launched from a manned aircraft (see “Learn More,” at right).

Designing an expendable UAV from

composites presents an obvious challenge: How to produce a viable

aircraft capable of carrying mission-specific communicators, sensors or

other equipment at a cost low enough to justify a single flight?

One

option is to use low-cost, automated methods for key parts. KaZaK

Composites Inc. (Woburn, Mass.) has demonstrated the feasibility of

pultrusion with innovative designs and manufacturing strategies for UAV

wings, as well as other high-value parts for space missions and

military applications.

To make expendable aircraft feasible, production and material costs have to be kept to a minimum, says KaZaK’s president Jerry Fanucci. Although pultrusion often fits the bill, “we don’t think of ourselves as a pultrusion company,” he maintains, pointing out, “we design composite parts, and if pultrusion is the right solution, then we use it.” According to Fanucci, KaZaK is a full-service design and production company, capable of developing not only UAV wings but also entire unmanned aircraft, including selection of the airfoil shape and definition of vehicle aerodynamics. “It ultimately depends on the performance requirements, but if pultrusion is the answer, then it works for aerospace as well as for industrial applications.”

Designing for low-cost manufacture

As most

composites engineers know, pultrusion is a continuous molding process.

A creel system pays out reinforcing materials, in the form of

unidirectional roving, woven cloth, multiaxials, braided preforms

and/or nonwoven mats that are continuously drawn through a moving

production line by a system of alternating pullers. Reinforcements, in

some cases, pass through a preheating furnace, which heats and dries

them to improve resin wetout. Materials then are positioned or shaped

as required. For example, woven cloth could be folded over or placed

off-axis as it passes through one or more forming devices. The

materials then are passed through an open resin bath with a doctoring

system that afterward removes excess resin. Alternatively, it enters an

enclosed injection die, where resin is forced under pressure directly

onto the reinforcements. The wet-out materials then immediately pass

into a heated steel pultrusion die, where they are compressed to the

final part shape and cured. When the cured part exits the die, it can

be cut to the desired length as it moves, with a traveling cut-off saw.

Pultrusion

produces parts with constant cross-sections, most commonly simple

tubes, rods, beams or flat plates — but any complexly-shaped

two-dimensional profile is possible, and even tapering profiles can be

considered, notes Fanucci: “A common misconception about pultrusion is

that it can only produce parts with unidirectional reinforcement but,

in fact, almost any multi-angle laminate can be achieved by using

pre-plied broadgoods or inline filament winding.” As a continuous

automated process, pultrusion can produce very high-quality parts with

tight tolerances of virtually unlimited length, he adds.

“Because

the reinforcements are always under tension, you can achieve very high

fiber alignment and straightness,” he says, contending that such

precision is often unattainable “with a hand layed part cured in the

autoclave, where the autoclave pressure can cause some distortion.”

Costs

are significantly lower for pultrusion than for any other composite

production methods due to several factors. Dry reinforcements and

liquid resin together cost less than prepregs, and labor costs are very

low because the process is automated. Other cost savings can be gained

in the tooling. Pultrusion dies are short, normally only 2 to 4 ft (0.6

to 1.2m) in length, so they can be produced fairly economically. “No

matter how long your part or the number of copies,” says Fanucci, “the

tool cost is the same, and relatively low compared to a layup tool.”

Evolving concepts for manufacturable wings

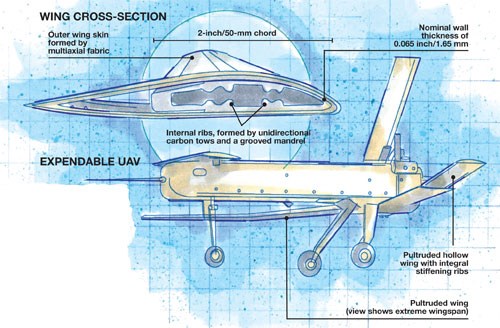

With an eye to these advantages, the company pursued and received two Small Business Innovation Research (SBIR) grants to design wings for weapons. The grant funded programs that evolved into a design for a telescoping wing for a swarm-type, long-loiter UAV, as well as the design for the company’s own disposable gliding UAV, developed for the U.S. Navy as an expendable, GPS-controlled sonobuoy delivery system.To keep part costs as low as possible, some design compromises had to be made, notes Fanucci. One of the wing projects, for example, involved an SBIR customer that provided the external aerodynamic wing shape, with an approximate 2-inch/50-mm chord. Previously developed as part of the client’s overall vehicle design, and necessary to achieve the UAV system’s performance, the wing shape was non-negotiable. But the means by which KaZaK might provide the stiffness required to combat air loads and produce sufficient lift in the wing was not prescribed and included a range of solid, hollow and internally ribbed options.

Based on

the given wing shape, KaZaK employed a finite element model based on

air loads and stiffness requirements. The goal was to determine the

composite laminate structure that could best handle the loads by

manipulating the fiber architecture while staying inside the required

outer aerodynamic shape. The company primarily used ANSYS software from

ANSYS Inc. (Canonsburg, Pa.) and SolidWorks from Dassault Systèmes

Solidworks Corp. (Woodland Hills, Calif.) to create the multi-ply wing

laminate. But Fanucci says the company also has access to other FEA and

CAD programs, when required by an application. The FEA analyses

prompted selection of a hollow wing design with lengthwise interior

stiffening ribs and a wall thickness of approximately 0.065 inch/1.65

mm.

During the selection process, an important consideration

was “design for manufacturability,” where the company looked at

available reinforcement material forms and considered how difficult it

might be to pultrude prospective designs: “Anyone looking at pultrusion

is interested in cost minimization,” says Fanucci. “So we often iterate

several designs with the customer to arrive at a compromise that gives

the needed performance, provides the best cost/weight value and is also

easiest to manufacture.” The lengthwise stiffening ribs, for example,

could be pultruded integrally with the wing, eliminating extra

manufacturing steps. However, one client design feature, a

several-degree root-to-tip twist to improve stall performance, was

eliminated. Although KaZaK previously had produced twisted, pultruded

wings, Fanucci points out that the cost is higher and, in this case,

the marginal improvement in flight did not justify the additional

expense: “For a consumable UAV, cost drives the design more than

aerodynamic performance.”

When the wing shape and laminate

design model were complete, the next step was to design the root end

termination, where the pultruded wing attaches to the vehicle body.

Depending on loads and other details, this feature can be a pivot or

other deployment mechanism, in metal or composite, and is usually

bonded into the hollow wing as an insert at the root end. Fanucci

explains that for some contracts, internal telescoping mechanisms are

needed inside the wing. These enable the wing to deploy, spanwise, as

the root section pivots. With all of the various design elements in

place, KaZaK turned to designing the pultrusion process.

Pultruding skins and ribs in one step

To make the hollow wing with interior stiffening ribs, the selected reinforcements included a stitched unidirectional carbon fabric manufactured by Fabric Development Inc. (Quakertown, Pa.), quadraxial carbon fabric supplied by Vectorply Corp. (Phenix City, Ala.) and continuous carbon tows from Grafil Inc. (Sacramento, Calif). The selected resin was aerospace-grade Epon 862 epoxy, supplied by Hexion Specialty Chemicals (Houston, Texas). The epoxy formulation is a proprietary “tweaked” version, modified with accelerators to ensure rapid cure at the pultrusion line speed (~12 inches/300 mm per minute).The

pultrusion line had to be tweaked as well. Multiple unidirectional tows

were fed in conventional manner from the creel and through the first of

two resin-injection dies. To ensure that the resin’s viscosity would be

low enough to thoroughly wet out the fiber, it was preheated prior to

injection. As the impregnated reinforcements exited the die, they were

pulled through a progression of “cards,” or machined plastic blocks

(see center photo, below), that bundled the tows together and gradually

manipulated and positioned the bundles around a stationary

airfoil-shaped mandrel, which was machined with grooves at the rib

positions. Simultaneously, layers of wet out quadraxial fabric were

pulled through formers that folded the materials around the outside of

the mandrel, enclosing and securing the tow bundles in place just

before they entered the second injection die, which is required to

ensure complete wetout of the laminate stack. Immediately afterward,

the layup was pulled through the heated die and cured. Parts were cut

to length, and the metallic root end terminations were bonded.

The

resulting wing has an intricate interior cross-section and a

fiber/volume fraction in excess of 60 percent — approximately the same

as the typical autoclave-cured prepreg part. Subsequent mechanical

testing, including cantilever and four-point bending tests, showed the

wing withstands loads predicted by the model, consistent with its

laminate design, says KaZaK.

Providing low cost and high quality

Often

overlooked by manufacturers of aerospace parts, pultrusion — as

demonstrated here — is clearly a viable candidate for certain

applications, where the very low cost and automated process can deliver

high-performance parts. “The best-performing composite structures are

not very practical if they can’t be economically manufactured,”

observes Fanucci, noting that KaZaK has performed numerous trade

studies that show how pultrusion can reduce the cost of carbon fiber

structures in a variety of markets by 50 percent or more, compared to

other fabrication techniques, yet deliver comparable fiber volume and

performance.

Related Content

SmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreRead Next

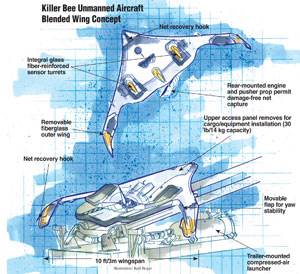

Blended Wing UAV

Unique unmanned craft's robust composite design a plus for rough duty.

Read MoreComposites enable micro air vehicle

Real-time sensing capability makes slow-flight VTOL MAV a "man replacement."

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More