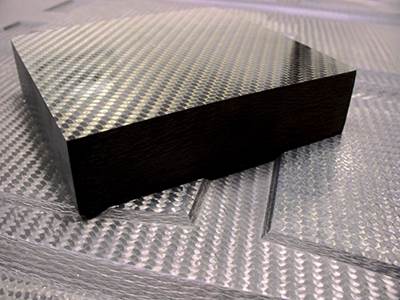

Out of Autoclave

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

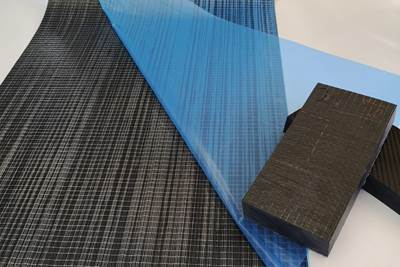

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreRUAG rebrands as Beyond Gravity, boosts CFRP satellite dispenser capacity

NEW smart factory in Linköping will double production and use sensors, data analytics for real-time quality control — CW talks with Holger Wentscher, Beyond Gravity’s head of launcher programs.

Read MoreHaydale Graphene awarded Innovate UK grant to develop smart composite tooling

The ESENSE project aims to replace costly autoclave processes with a multi-zone OOA self-heated tooling solution, potentially cutting lead times by 20%, energy by 15% and halving the cost of autoclave manufacturing.

Read MoreDLR Institute of Structures and Design releases video on TB-Rumpf welded thermoplastic composites

Autoclave-free consolidation and resistance welding validated for future aircraft thermoplastic composite fuselage.

WatchHexcel introduces G-Vent technology for thick, OOA marine structures

Hexcel marine prepregs are available with G-Vent integrated, enabling out-of-autoclave processing with reduced time, cost and autoclave-comparable porosity for highly loaded masts and foils without debulking.

Read MorePlant tour: Victrex Composites Solutions, Bristol, Rhode Island, U.S.

De-risking thermoplastic composites at industrial scale via hybrid overmolding.

WatchMiddle River Aerostructure Systems displays aeroengine nacelle using AFP and RTM composites

Highlights technologies and manufacturing processes that enhance aeroengine operating efficiency while reducing fuel consumption and noise.

Read MoreAirbus C295 technology demonstrator makes maiden flight, proves novel design, manufacturing processes

C295 Flight Test Bed 2 (FTB2) tests OOA composite semi-morphing wing, flaps and flap tabs, as well as SatCom antenna for future turboprop aircraft.

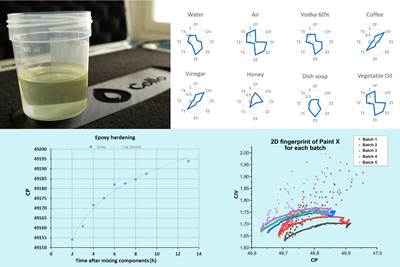

Read MoreFingerprinting liquids for composites

Collo uses electromagnetic sensors and edge analytics to optimize resin degassing, mixing, infusion, polymerization and cure as well as monitoring drift from benchmarked process parameters and enabling in-situ process control.

Watch

.jpg;maxWidth=300;quality=90)