Out of Autoclave

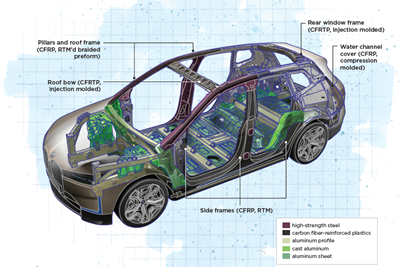

BMW rolls out multi-material Carbon Cage with 2022 iX vehicle line

For its new battery-electric iX sports activity vehicle, BMW combines CFRP strategies from previous i3, i8 and 7-Series designs and adds CFRTP for a lightweight, rigid frame.

WatchMETEOR project studies optimization of thermoplastic prepreg production

Completed project aimed at optimizing and reducing the cost and energy involved in CFRTP prepreg manufacture, with the end goal of industrialization.

Read MoreFully U.S.-made fairing launched into space features OOA composites

A United Launch Alliance Atlas V rocket launched a U.S. defense satellite into space. The payload fairing, produced by RUAG Space, is composed of OOA CFRP face sheets.

Read MoreHigher performance, lower cost helicopter rotor blades developed with OOA, FAA-qualified composites

Erickson Inc. and partner Toray Advanced Composites replaced legacy aluminum S-64 main rotor blades with out-of-autoclave, multi-material composite alternatives.

Read MoreDesigning for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

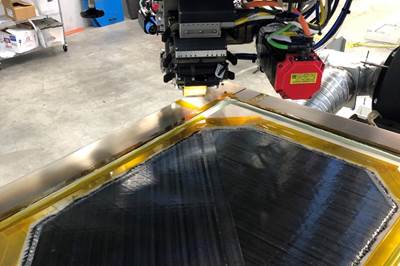

Read MoreElectroimpact, Toray, Janicki advance technologies for rapid, large-scale thermoplastic parts manufacture

Project combines Electroimpact high-speed AFP equipment, Janicki’s OOA heated layup tooling system and Toray Cetex TC1225 low melt PAEK UD tape for deposition rates of up to 4,000 inches/minute.

Read MoreSpirit AeroSystems Europe delivers first set of A320 Family RTM spoilers

Redesigned spoilers developed via a highly automated advanced manufacturing, out-of-autoclave (OOA) process pioneered by Spirit.

Read MoreOut-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

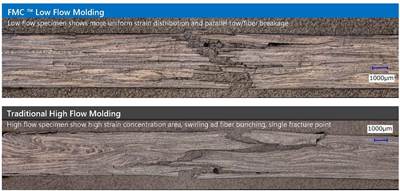

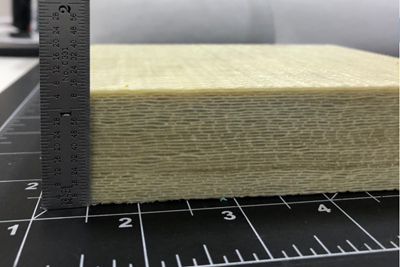

Read MoreForged molding compound: Extending SMC capabilities

New material, design, process combination approaches prepreg performance with chopped carbon fiber SMC.

Read MoreNew thermoset matrix resin offers fast, low-temp, tunable cure

HARP Rapid is a new thermoset resin chemistry for liquid molding processes that offers a fast, tunable cure profile, and a Tg that exceeds the material’s cure temperature.

Read More