ColloidTek Oy (Collo, Tampere, Finland) is a spin-off from Tampere University, co-founded in 2017 by ceramicist and materials scientist, Matti Järveläinen, who is also the company’s CEO. “Colloid” refers to the suspension of particles in technical ceramics. “My PhD is in measurement technologies for ceramic processes,” he explains, “and where we started was analyzing the dispersing process and stability of ceramic suspensions.”

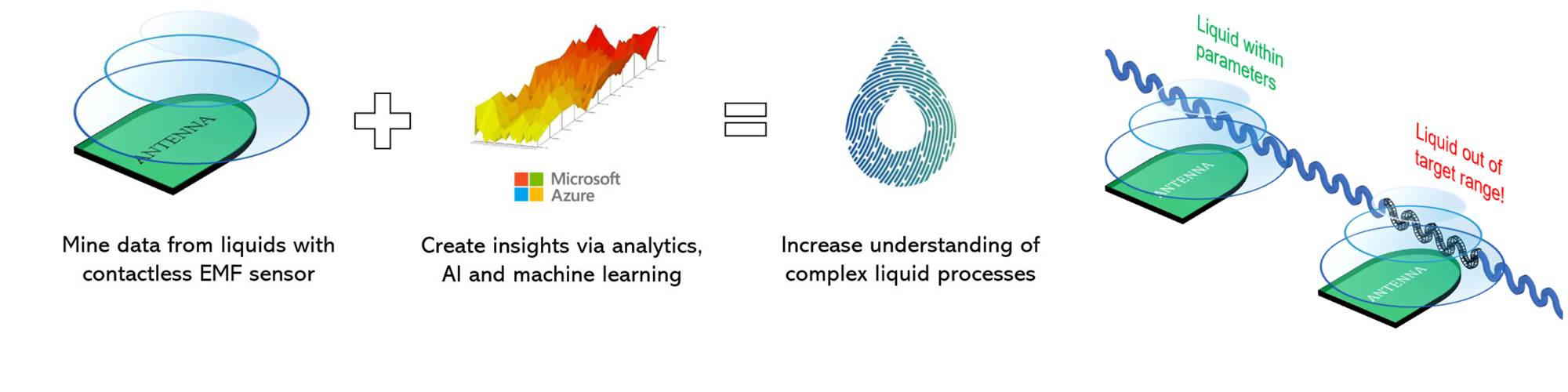

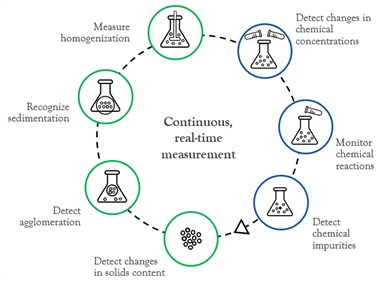

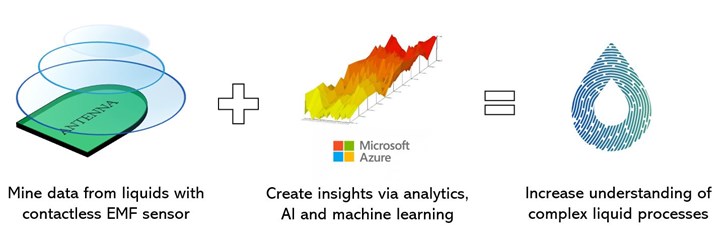

Collo has developed an electromagnetic field (EMF) sensor which constantly measures a liquid being processed and analyzes how that liquid is changing, explains Tuuli Potila, marketing manager for Collo. “Our combination of proprietary Collo sensors, signal processing and data analytics technologies provides a solution to measure what we call liquid fingerprints. Our sensors are installed directly into a process line, giving accurate real-time data and enabling customers to see inside their processes, achieve advanced process control and improve efficiency.”

“We provide continuous, contactless monitoring of liquids and how they are changing during processing with regard to chemical reactions, viscosity, homogeneity of mixed components, etc.,” says Järveläinen. “We then use artificial intelligence and analytics to convert this data into better understanding of the process. We correlate our readings to quantities that can have set limits and alarms, such as rheological viscosity, homogeneity or degree of polymerization. If you just take samples into the lab, you are only seeing a snapshot of the process. It's like driving on a motorway and just opening your eyes for one minute each hour and trying to predict where the road goes from that.”

The Collo sensor and technology solution is providing a way to see the path forward in composites processes continuously, in real-time, so that these processes can be directed based on data and then controlled and automated to become intelligent.

Collo sensors

Currently, sensors are configured as either a Collo Probe, which can be immersed into a liquid, or a Collo Plate, which is installed into the wall of containment/mixing vessels or process pipes/feed lines. The Collo Plate is shielded with tempered glass, enabling use at temperatures up to 130°C, and is being tested for continuous use in temperatures up to 150°C. Although the Collo sensor technology itself has no theoretical temperature limitation, says Järveläinen, the Collo Probe maximum service temperature depends on its housing. The first-generation polyurethane housing is limited to 90°C, but a second-generation model using polyetheretherketone (PEEK) is being tested for use up to 150°C.

Collo sensors can be used in all types of liquids, says Potila, including suspensions, emulsions, pastes, gels, slurries, creams, solvents, resins, adhesives, coatings, and multi-component liquids, as well as for complex processes used with such liquids. “We interrogate the sensor in 2-second intervals and the frequency is in the megahertz range,” notes Järveläinen. “We have good control of the electromagnetic field the sensor emits and have developed it to see into the resin or paint, for example.”

In fact, Collo sensors can read through any nonmetallic material. Videos on the Collo.fi website show various demos, including measuring coffee. “You can put your coffee mug on the sensor, and it will send and receive an electromagnetic field through the bottom of the coffee mug with enough sensitivity to recognize one grain of salt added to the coffee,” says Järveläinen. “For composites, then, it doesn't much matter if you have fibers, or if you have a very thick or thin medium, the sensor still has quite high sensitivity.”

So, thinking of this coffee mug example, would a Collo sensor be able to read through the bottom laminate of a composite joint and see into the adhesive? Or read through a composite tool to monitor the resin flow front during infusion of a composite part? “It depends on the size and structure of the antenna and how we engineer it in the sensor unit,” says Järveläinen. “For example, we have engineered a sensor unit about the size of a coin that will read roughly two centimeters into a structure, but we have also used a larger sensor which can measure 5-10 centimeters in depth. When you have a larger penetration depth, it also measures a larger volume and gives you a bit better estimate on the quality of the liquid.”

Non-contact, electromagnetic measurement

Collo sensors measure two main variables — ion viscosity and permittivity. These basic dielectric properties are also measured by dielectric analysis (DEA) sensors. In my blog, “DC dielectric sensors for industrial composites production”, I explained that DEA sensors apply a voltage between two electrodes in contact with a resin or adhesive and then measure the change in signal between these electrodes. I further discuss DEA sensors in my blog, “Combining AC and DC dielectric measurements for cure monitoring of composites”.

“DEA sensors need to contact the resin and are measuring it in the area between those two electrodes, which must be in close proximity to each other,” explains Teemu Yli-Hallila, Collo co-founder and CTO. “The Collo sensor is just one electrode, around which the sensing electric field is formed. This makes it easier for Collo sensors to read through nonmetallic materials and measure liquids without contacting them.”

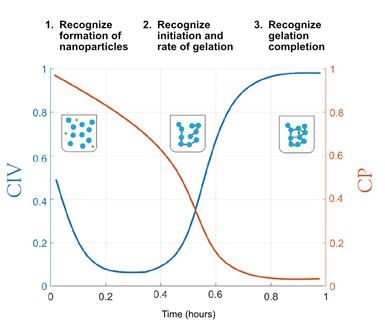

“Dielectricity is a phenomenon by which an electric field is conducted in electrically insulating materials like oil and resin,” says Järveläinen. “In these materials, there are electrically polar elements that align with the electric field. Because these elements have a charge and a mass, when they move, they consume and store some of the energy from the electric field. The parameter that quantifies dielectricity is called permittivity. It is a complex number that has two parts — one describes the strength of polarization and the other describes energy losses when polar elements orient in the electromagnetic field. Collo measures both and we call them Collo permittivity (CP) and Collo ion viscosity (CIV) because we are not giving these in terms of SI units, as is typical, so we differentiate it as our measurement.”

“Dielectricity in materials can be caused by four polarization mechanisms that act in different frequencies of the electromagnetic field,” he continues. “Collo is set to work in the range of two particular mechanisms — called dipolar and interfacial polarization. This enables us to see, for example, impurity ions dissolving into liquid, which would increase the electric losses. But we can also see when the liquid changes from low-viscosity movement of ions to a solid because this changes the strength of polarization.”

The ability for measurement without contacting the resin or composite being controlled is an advantage and why thermal flux sensors were chosen to monitor resin flow and cure for the INNOTOOL 4.0 project (see “Speeding RTM with heat flux sensors”). However, compared to DEA and heat flux sensors, Collo has developed its technology to recognize and measure a total of eight variables. “This increases the accuracy and versatility of Collo sensors,” says Potila, “and gives them very broad capabilities.”

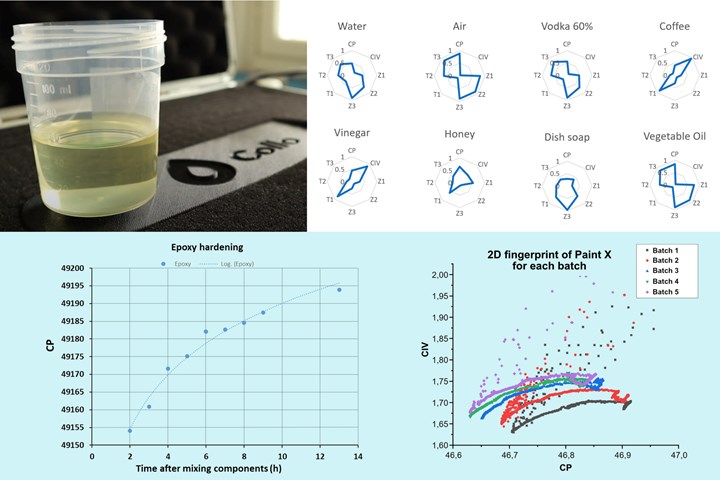

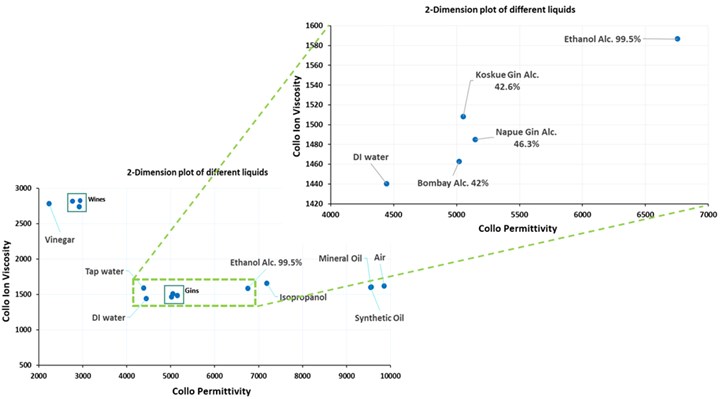

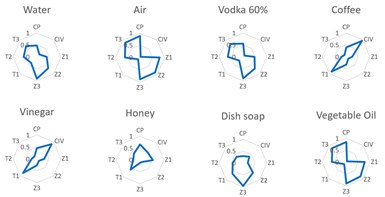

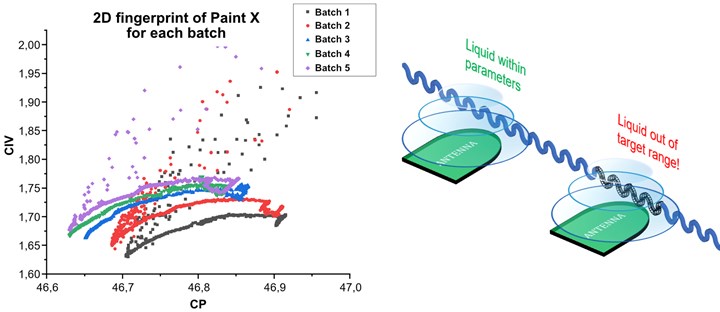

Graph of Collo Permittivity versus Collo Ion Viscosity (top) and spider plots of 8 variables measured by Collo for different liquids (bottom).

Even by graphing just the two main variables of CP and CIV, she notes, “it is possible to show that each liquid has its own signature. And then, in the figure at right, we have zoomed into a zone where we can even distinguish between different types of gin.” (Click on graph to enlarge.)

“But it's pretty difficult to show the additional six variables in a meaningful way,” says Järveläinen. “So, instead we made spider plots to help visualize the different parametric fingerprints of common liquids.”

Real-time, in-situ measurement

“So, the solution we are offering is real-time, inline measurement directly from the process,” says Järveläinen. “Our system then converts that data into physical quantities that are understandable and actionable, like rheological viscosity, and it helps to ensure high-quality liquid processes and products. It also allows optimizing the processes. For example, you can shorten mixing time because you can clearly see when mixing is complete. So, you can improve productivity, save energy and reduce scrap versus less optimized processing.”

Mixing is an issue that I discussed in “HP-RTM for serial production of cost-effective CFRP aerostructures”. RTM aircraft structures have only used 1K (one-component) systems mixed by the supplier, but these require cold shipment and storage, which increases cost. “Now we are considering 2K systems, but the challenge is to ensure the mixing quality,” explains Jan Schiller, lead contact for resin transfer molding (RTM) technologies at the Composites Technology Center (CTC, Stade, Germany), a subsidiary of Airbus Operations GmbH. For Shiller, the assurance of mixing quality “requires detection of the mixing ratio and the mixed resin quality [across the part]. Both are needed for Airbus qualification of a new material.” Collo, then, could be placed into a metal tool or beneath a composite tool and monitor the homogeneity of the mixed resin as it is infused/injected through the part.

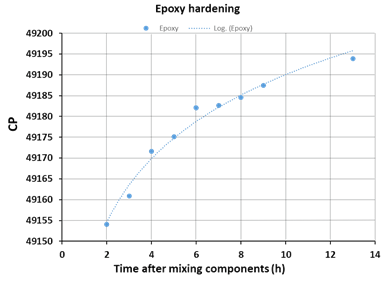

Mixing of 2-component resins can also affect the rate of polymerization. Collo sensors are being used by adhesives supplier Kiilto (Tampere, Finland) to measure polymerization and hardening. “Kiilto is using our sensors to help their customers who use adhesives in layered wood flooring and in other composites applications,” says Järveläinen. “We are measuring the polymerization reaction rate, and then we make an approximation to predict hardening time. So, after a few minutes, we can predict when hardening will be complete.” See the Kiilto video below about how they are using Collo sensors.

“The system can also give indications to use more component A or component B,” he continues, “because the flooring manufacturer can directly control the proportions of each component in their mixing equipment. What they see is inline, and that has been quite interesting because both the resin manufacturer and their customer using the resin can see how the process is working.”

“We can also use machine learning to correlate our measurements to mechanical viscosity,” says Järveläinen, which is key, “because our customer doesn’t want to look at arbitrary data from a sensor. What they want is to understand when they can go to the next process step or how long they have to finish a layup, for example. And for that, you must do the analytics, incorporating multiple sensors, and then you use machine learning, which speeds up the process to get something relevant for the customer. You have to have all of these steps to offer a real solution.”

“Kiilto is using our sensors inline to offer premium customer service,” notes Järveläinen. “They can tune the composition of adhesives for individual customers and at the same time monitor how these are working. When you see how the resin is interacting in your customer’s process and how your customer is interacting with your product, that is something exciting because it includes the sensor, cloud computing, machine learning and AI (artificial intelligence) and this is changing how the supply chain can work together.”

Monitoring a parameter

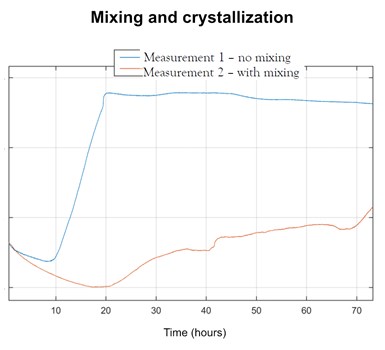

Mixing prevents crystallization in this solution of nitrate salts in water. Both mixing and crystallization can be monitored with a Collo sensor.

Tracking a single parameter is one of the three main ways that Collo’s customers are using its sensor solution. ABB Finland (Helsinki) uses Collo sensors to control the viscosity of resin used in the production of electric motors. “They are linking the sensors to a rheometer to basically run their process through a laboratory measurement,” says Järveläinen. “They have been doing lab testing for decades, so they know what a good rheological viscosity is, but now, they can measure it in real-time, in-situ. So, our sensors don’t output the rheological viscosity —because that requires some mechanical stirring to measure — but instead, we use machine learning to convert our measurements into mechanical viscosity because we know how they correlate. So, we analyze a combination from the resin’s fingerprint that gives the mechanical viscosity and ABB no longer needs the lab to run the measurement. This is one way to use Collo.”

Dielectric sensor supplier Synthesites (Uccle, Belgium) is doing the same thing by using their sensors to estimate the glass transition temperature (Tg) of resin during infusion and RTM processes. This then lets part manufacturers move away from legacy cure recipes and instead exploit material state management based on in-situ resin data in real-time.

Kiilto uses Collo sensors to also monitor other parameters, like sedimentation — a shelf-life issue where an adhesive eventually separates into a layer of low-viscosity solvent or water on top with hardened solids at the bottom of the container. By using the Collo sensor, Kiilto monitored various formulations to see which offered the slowest sedimentation, enabling optimization of that adhesive’s shelf-life.

Monitoring a batch

“Another way to use Collo sensors,” says Potila, “is to monitor each process phase or batch so that they can be benchmarked and compared. We did a pilot study with Pyynikin Panimo (Tampere, Finland) to fingerprint their beer production and optimize their process batches with comprehensive, real-time monitoring.” She notes that online monitoring of the whole beer production process is almost nonexistent. “Most beer production is monitored simply with individual measurements such as temperature and dissolved starches. However, the raw materials exhibit seasonal changes, so that the process is subject to batch-to-batch variations.”

“Monitoring with Collo sensors has let Pyynikin Panimo see real-time changes and take immediate action if necessary,” she continues. “Having a process profile of each batch allows them to spot a misbehaving raw material. Also, because they can now see the dynamics of their process per batch, they can set more optimal parameters with limits and intervene when the batch is out of spec. This helps them to stabilize and improve quality and they now have the knowledge to control even the unpredictable fermentation process.”

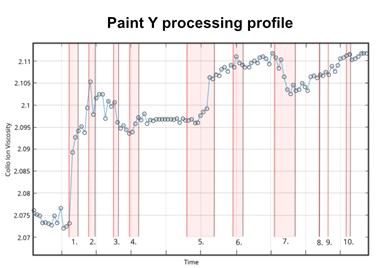

Collo generates a one-dimensional view as ingredients 1. through 10. (red highlighted columns) are added to paint Y.

Järveläinen describes another customer example, this time a complete paint manufacturing process. “Using our sensors, we can see where each ingredient has been added and how each changes the fingerprint of the paint liquid. We also monitor how the batches are changing. So, the system creates a profile for the process as the different components are added. Some of them help volatiles come out of the paint and others make sure that it doesn't foam during mixing. And for each of this company’s paint products, we have this type of profile, so that they now get a warning if the product profile varies from batch to batch. And, for example, if it starts to foam, they can pause the process briefly or add more anti-foaming agent, etc.”

Collo sensors can perform batch-to-batch monitoring and detect out-of-spec steps immediately by setting limits and alarms. This system could also be integrated with process equipment for automated, closed-loop control.

Monitoring a process

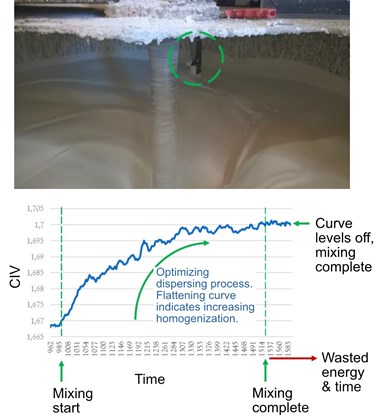

Collo probe submerged in paint mixing vessel (green circle at top) detects when mixing is complete, saving time and energy.

The third use of Collo sensors, says Järveläinen, is to optimize process steps. “Our sensors can recognize when mixing is complete, for example, so waste of time and energy are avoided while quality is assured. Alarms and process equipment control can be set to only allow the next step once the specified homogeneity has been reached.”

Degassing resins is another example. This is a common procedure in composites before resin infusion processes in order to avoid porosity in the finished part. “For one of our customers, the degassing process can take hours to more than a day,” says Järveläinen. “This impairs their production speed because they only have so many reaction vessels. So, it is important to know when the process is actually complete.” One can imagine extrapolating this to better utilization of curing tools and equipment based on real-time monitoring of resin polymerization and cure.Going further, however, Collo sensors can be used to advance process knowledge so that parameters or materials can be changed to reduce process times permanently. “For example, you have a spec that says add three kilograms of this additive and then mix for 30 minutes,” says Järveläinen. “But sometimes the quality of material is higher so that much less additive and/or mixing time is required. Thus, you can first improve your efficiency by basing process control on the actual material state, but then you can benchmark your raw material specifications and extend that improvement.”

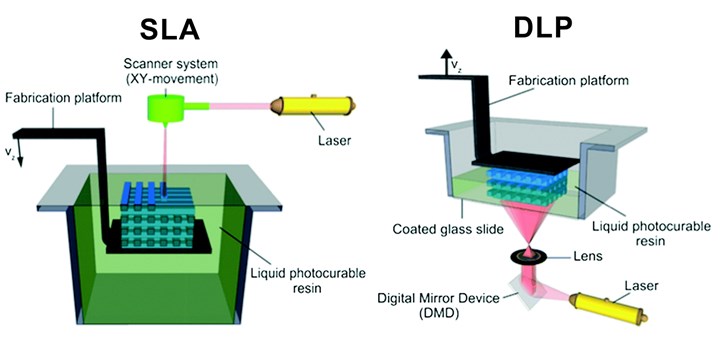

A final example is the use of Collo sensors for 3D printing complex-shaped ceramics using stereolithography (SLA). This additive manufacturing technique uses a light to selectively cure the surface of a liquid containing photopolymerizable monomers, photoinitiators and other additives. When the light-activated polymerization is complete for the designated lines and points of one layer, the system exposes the next layer. For ceramics, the SLA liquid has micro/nanometer-scale ceramic particles added in suspension. Where light is directed, the ceramic particles will be uniformly surrounded by polymer. Finished 3D “green” prints will then be sintered into finished parts, much like conventional ceramics.

Comparison of stereolithography (SLA) vs. digital light processing (DLP). Note, Fortify uses a version of DLP to produce custom microstructures in high-resolution, 3D printed composite parts. Source | Royal Society of Chemistry and “DLP vs SLA – 3D Printing Technologies Shootout” by Ricardo Pires, all3DP.com and featured in the CW blog: “Magnetic 3D printing the next generation of composites”.

In order to produce good parts, the ceramic suspensions must maintain appropriate viscosity and homogeneous dispersion throughout the printing process. As discussed above, Collo sensors can indeed be used to monitor the viscosity and homogeneity of the process liquid, but their utility goes even further. “We are working with a few universities to analyze the 3D printing polymerization in the SLA printers to optimize the layer thickness. Because they are hardening the print solution with light, they need to constantly adjust the intensity during the process based on the suspension and the shape being printed. Our Collo sensors allow us to see the polymerization in this mixture of ceramics and copolymers, which we can then use to control the light intensity in real-time.” (See In-line monitoring of ceramic resins used in stereolithography via high-frequency dielectric analysis.)

Integrating sensors for composites

Obviously, Collo’s solution was not developed specifically for composites. “I don’t think you will find many sensor companies that only work with composites,” says Järveläinen. “It’s not that the composites industry is too small, it’s that any one industry will be limited. For example, we are testing Collo in the paper industry to measure the chlorine solution that is used in the pulp making process. But the number of factories in the world for a given process is small — say, between 10 and 100. And then, out of those limited factories using this particular process, only a certain percentage are of an age where our sensors can boost their production. The older factories are structured in a way that it doesn’t help if we can improve their sub-processes. This dynamic plays out across multiple industries, so that for each industrial process, the market available will be rather small.”

Hence, the need for sensor suppliers to work across multiple industries, which makes it difficult to be composites specialists. Even so, Järveläinen doesn’t believe in creating a universal platform for sensor integration. “But I do believe in keeping the interfaces open,” he says. “From the sensor manufacturer point of view, to build a customized system for each vastly different process would require a new interface to be developed each time, and the costs would be too high. That's why I would build an open interface, and then all the sensor providers could give these interfaces to their customers, so that customers can then customize the solution to their needs.”

“I can’t teach you how to make better composites, but I can tell you how our sensor is going to work, once you help me to understand your process.”

Järveläinen cites Siemens Mindsphere as an example of a platform where you can integrate multiple arrays of different sensor types . But it doesn’t resolve the fundamental problem, which is the customer’s lack of knowledge regarding how to integrate these various sensors into their processes. “Most customers don't have sensor experts in their companies,” he continues. “And the sensor manufacturers most often talk in their own sensor language, not that of composites. At the moment, there is no middleman who can help the sensor producers talk with the customers. And the problem is, you as the customer, need to understand which of the sensing technologies are the best for each use case. So, it takes a lot of effort to test how different sensors work. Even for us, it has taken quite a lot of effort, for example, to understand how to link our sensor reading with polymerization data. And for that, we have built an AI model that interprets this from the curve and then alerts when you are ready to go to the next stage of production.”

The need for AI brings up another point. “So, the sensors provide raw data,” says Järveläinen, but then someone — either the end-use customer or the sensor manufacturer — must build an analyzer that works with the sensor to get the information needed for understanding and controlling the process. “For example, with dielectric sensors,” he explains, “if you’re my customer, you would say ‘I don’t care about seeing the electrical resistivity of the liquid but just need to know when it's ready to go to the next stage.’ This then means that you need to understand what variations in the material and process you want to monitor.”

What becomes clear is that the path to integrating sensors for composite processes requires a back-and-forth exchange of information between the sensor manufacturer and the customer. “Some days, I'm talking with pharmaceutical companies and with companies who are producing milk,” says Järveläinen, “and other days, I am trying to speak the language of composites. I can’t teach you how to make better composites, but I can tell you how our sensor is going to work, once you help me to understand your process.”

Related Content

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More