Processes

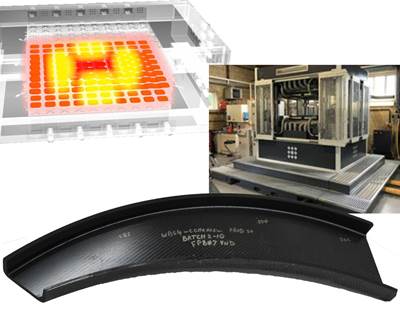

Material choices for the Corvette rear bumper beam

From fabrics to resins, a number of new combinations of materials went into the making of the world’s first curved pultruded automotive part.

Read MoreIPS Adhesives establishes Center of Excellence in North Carolina

The move centralizes the company’s North American R&D and customer service activities, with a focus on faster response times and increased output.

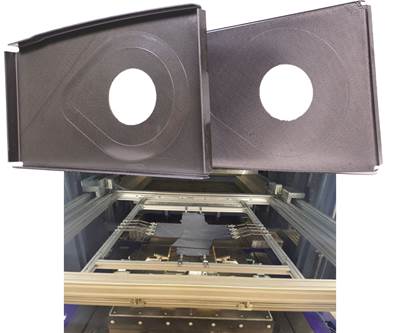

Read MoreRAPM development with PtFS

Boeing-led program explores rapid part cycles using automated, 180-channel thermal control molding cell for infusion, thermoset prepreg and thermoplastic composites.

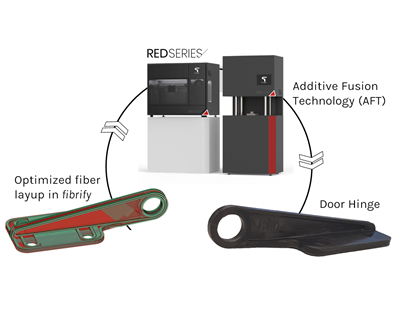

Read More9T Labs, Arkema present new manufacturing approach for small aerospace parts

The companies demonstrate cost-competitive series production of structural composite parts using carbon fiber/PEKK materials and additive manufacturing.

Read MoreNovel prepreg for compression molding in RAPM

Solvay and Boeing combine aerospace performance with process knowledge for high-rate, low-cost composites production.

WatchCurve in the road: First curved pultruded auto parts

Thomas Technik + Innovation KG’s radius pultrusion process unlocks new possibilities for the automotive market and beyond.

Read MoreJEC World 2020 preview: BigHead Fasteners

BigHead is launching Core Range, a new range of fasteners for both surface bonded and embedded applications.

Read MoreYG-1 solid-carbide routers designed for faster composites machining

Four new solid-carbide fiberglass routers have been launched for CNC or hand routers to handle everyday composite machining.

Read MorePark Aerospace Corp. introduces mid-toughened epoxy resin system

The E-752-MTS mid-toughened 350°F (177°C) cure epoxy system is designed for primary and secondary aircraft structure applications.

Read MoreTooling Tech Group expands moldmaking facility

A 10,000-square-foot expansion to the Ohio-based thermoforming and compression mold manufacturing facility will be completed later this year.

Read More